2 月 . 20, 2025 12:32

Back to list

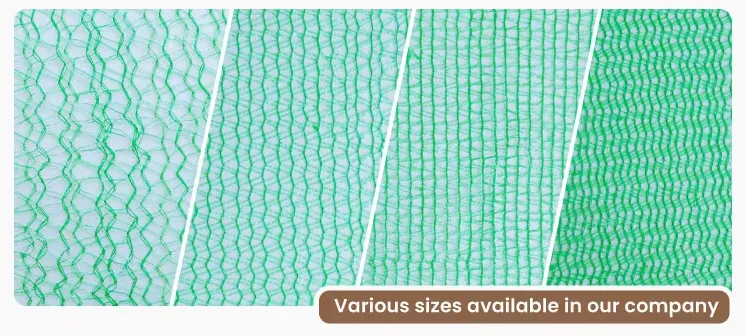

Plastic Flat Nets

Steel wire mesh for concrete is a crucial element in modern construction, offering a blend of durability, flexibility, and efficiency. This vital product enhances the structural integrity of concrete, making it indispensable for both small-scale and large-scale construction projects. The unique benefits and applications of steel wire mesh are vast, making it a preferred choice among builders and engineers alike.

Another significant benefit of steel wire mesh is its contribution to sustainability in the construction sector. By increasing the lifespan of concrete structures, it reduces the need for frequent repairs and replacements, leading to a substantial reduction in material consumption over time. Moreover, steel is one of the most recycled materials globally, supporting eco-friendly construction practices. This aligns with modern trends towards sustainable building operations and reduces the environmental impact associated with new construction projects. From an engineering perspective, the use of steel wire mesh in concrete is backed by extensive research and field studies, underlining its effectiveness and reliability. Experts in the field consistently cite steel wire mesh as a superior reinforcement solution due to its high performance under tensile and shear stresses. Furthermore, it conforms to international building codes and standards, providing assurance that it meets the necessary safety and quality criteria for construction applications around the world. The prominence of steel wire mesh in concrete is further supported by endorsements from industry authorities and the gravitation of leading construction companies towards its adoption for high-profile projects. Case studies and testimonials abound, highlighting successful implementations where steel wire mesh has contributed to increasing the service life and safety of concrete structures. Ultimately, its proven track record and adaptability make steel wire mesh a preferred choice for concrete reinforcement. Whether for residential sidewalks, industrial flooring, or major infrastructure development, its benefits are clear and compelling. Industry professionals seeking a reliable and efficient reinforcement solution for concrete construction can confidently rely on steel wire mesh to deliver outstanding performance, value, and peace of mind.

Another significant benefit of steel wire mesh is its contribution to sustainability in the construction sector. By increasing the lifespan of concrete structures, it reduces the need for frequent repairs and replacements, leading to a substantial reduction in material consumption over time. Moreover, steel is one of the most recycled materials globally, supporting eco-friendly construction practices. This aligns with modern trends towards sustainable building operations and reduces the environmental impact associated with new construction projects. From an engineering perspective, the use of steel wire mesh in concrete is backed by extensive research and field studies, underlining its effectiveness and reliability. Experts in the field consistently cite steel wire mesh as a superior reinforcement solution due to its high performance under tensile and shear stresses. Furthermore, it conforms to international building codes and standards, providing assurance that it meets the necessary safety and quality criteria for construction applications around the world. The prominence of steel wire mesh in concrete is further supported by endorsements from industry authorities and the gravitation of leading construction companies towards its adoption for high-profile projects. Case studies and testimonials abound, highlighting successful implementations where steel wire mesh has contributed to increasing the service life and safety of concrete structures. Ultimately, its proven track record and adaptability make steel wire mesh a preferred choice for concrete reinforcement. Whether for residential sidewalks, industrial flooring, or major infrastructure development, its benefits are clear and compelling. Industry professionals seeking a reliable and efficient reinforcement solution for concrete construction can confidently rely on steel wire mesh to deliver outstanding performance, value, and peace of mind.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024