2 月 . 20, 2025 12:04

Back to list

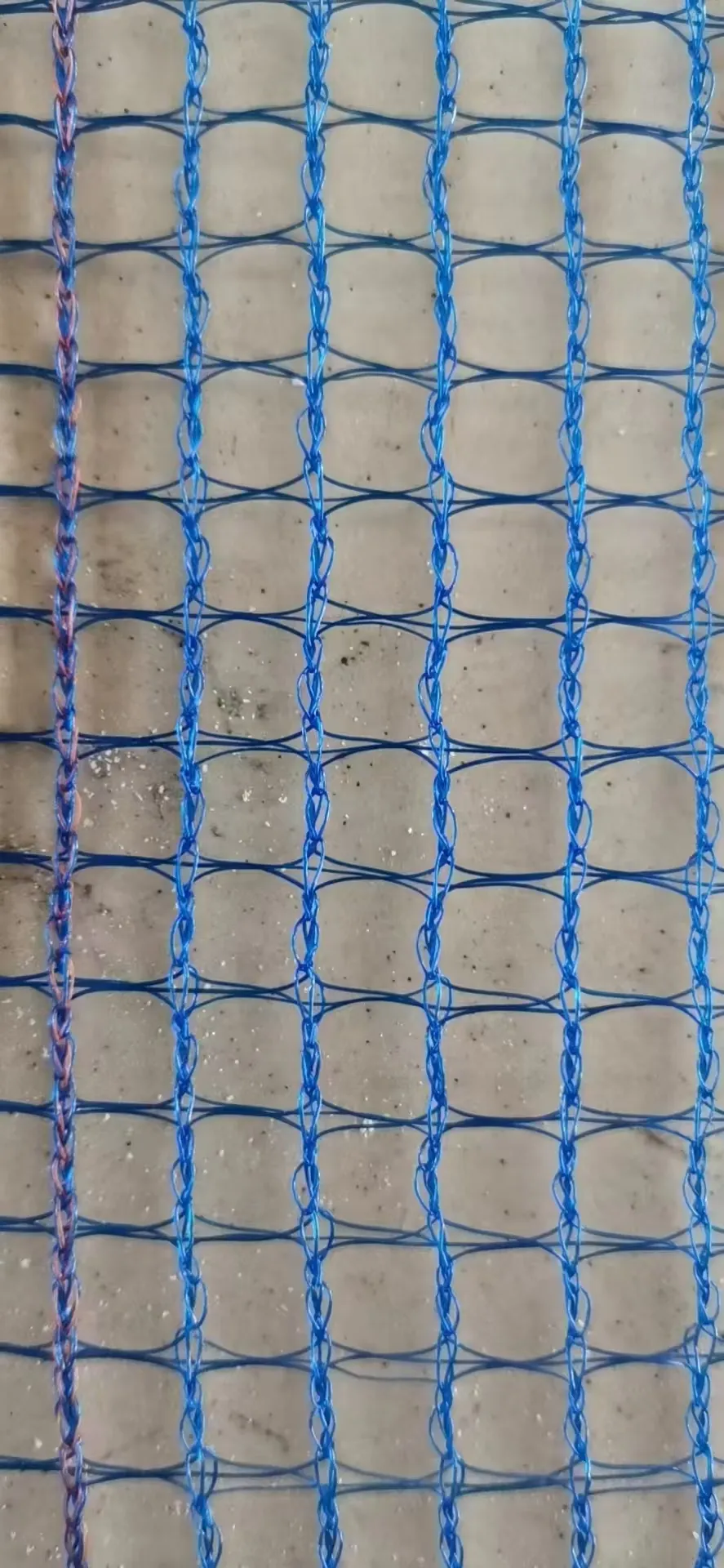

Plastic Flat Nets

Wire mesh filters represent an essential component in a variety of industrial applications due to their versatility, efficiency, and durability. These filters are woven with precision from metals like stainless steel, bronze, or brass, depending on the specific requirements of the application they serve. As a product, wire mesh filters are indispensable for industries ranging from pharmaceuticals to automotive manufacturing, underlining the criticality of choosing the right manufacturer. Discovering trusted wire mesh filter manufacturers involves knowing the intricacies of their production process, quality standards, and expertise in pushing industry boundaries.

In finding the optimal wire mesh filter manufacturer, a comprehensive assessment of these facets should be undertaken. Research plays a vital role, as industry reviews, case studies, and client testimonials provide a glimpse into a manufacturer’s reliability and product performance. Networking with peers and industry experts can also uncover lesser-known but high-quality manufacturers. Prospective clients are encouraged to visit manufacturing sites when possible, gaining firsthand insight into production processes and quality control measures. Additionally, rapid advances in environmental regulations necessitate manufacturers to adopt sustainable practices. Leading manufacturers are now exploring eco-friendly materials and energy-efficient production methods to reduce their environmental footprint. Clients today are increasingly conscious of sustainability, and selecting a manufacturer aligned with these values not only supports environmental efforts but also aligns with modern ethical commerce practices. The future of wire mesh filters lies in continual innovation and adaptation. With new challenges arising, such as the need for filters that can withstand extreme temperatures or resist corrosive chemicals, the manufacturers who thrive are those who invest in research and development. Collaborations with academic institutions and participation in cutting-edge research prolong their competitive edge, creating opportunities for breakthroughs that will define the industry’s direction in years to come. In conclusion, securing an impactful partnership with a wire mesh filter manufacturer encompasses evaluating quality assurance, technological expertise, established authority, and trustworthiness. By assessing these elements with diligence and foresight, industries can ensure they are equipped with reliable filtration solutions, thereby enhancing operational efficiency and safeguarding their processes against unforeseen disruptions.

In finding the optimal wire mesh filter manufacturer, a comprehensive assessment of these facets should be undertaken. Research plays a vital role, as industry reviews, case studies, and client testimonials provide a glimpse into a manufacturer’s reliability and product performance. Networking with peers and industry experts can also uncover lesser-known but high-quality manufacturers. Prospective clients are encouraged to visit manufacturing sites when possible, gaining firsthand insight into production processes and quality control measures. Additionally, rapid advances in environmental regulations necessitate manufacturers to adopt sustainable practices. Leading manufacturers are now exploring eco-friendly materials and energy-efficient production methods to reduce their environmental footprint. Clients today are increasingly conscious of sustainability, and selecting a manufacturer aligned with these values not only supports environmental efforts but also aligns with modern ethical commerce practices. The future of wire mesh filters lies in continual innovation and adaptation. With new challenges arising, such as the need for filters that can withstand extreme temperatures or resist corrosive chemicals, the manufacturers who thrive are those who invest in research and development. Collaborations with academic institutions and participation in cutting-edge research prolong their competitive edge, creating opportunities for breakthroughs that will define the industry’s direction in years to come. In conclusion, securing an impactful partnership with a wire mesh filter manufacturer encompasses evaluating quality assurance, technological expertise, established authority, and trustworthiness. By assessing these elements with diligence and foresight, industries can ensure they are equipped with reliable filtration solutions, thereby enhancing operational efficiency and safeguarding their processes against unforeseen disruptions.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024