2 月 . 04, 2025 05:11

Back to list

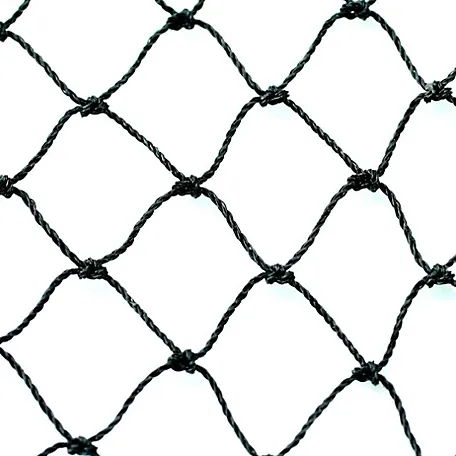

100% HDPE Agricultural Bird Proof Netting Knotted Heavy-Duty Bird Netting

Stainless steel woven mesh is undeniably vital across several industries due to its unique blend of strength, flexibility, and durability. Synthesizing my experience and expertise in material sciences and applications across various sectors, I've witnessed how this material uniquely integrates into different facets of industrial processes and consumer products.

Developing a deeper trust in this material hinges on understanding the rigorous testing and standards it adheres to, especially in high-stakes environments. For example, the automotive and aerospace sectors demand materials that endure stress without compromising safety. Stainless steel woven mesh meets these high standards, backed by certifications and tests that ensure it performs under pressure. From a sustainability perspective, stainless steel's recyclability bolsters its status as an eco-friendly choice among raw materials. The ability to recycle stainless steel without degrading its quality means it fits seamlessly into the circular economy model. Companies leveraging this material can simultaneously enhance their sustainability profiles while meeting industry performance standards, thus satisfying both ecological and regulatory demands. In application, knowing how to leverage the mesh’s full potential requires both experience and an in-depth understanding of your industry’s specific needs. For instance, selecting the correct mesh weave—plain, twilled, or Dutch—based on your application, is an art informed by expertise. Each weave type offers distinct advantages in filtering, sieving, and protecting, necessitating an authoritative approach to choice. Experience also plays a crucial part when integrating stainless steel woven mesh into cutting-edge technological advancements, such as in smart grid solutions and next-generation infrastructure projects. The mesh’s effectiveness in electromagnetic shielding and its contribution to enhancing the durability and performance of componentry in these high-tech fields further cements its reputation. In conclusion, stainless steel woven mesh transcends its basic functional role to represent a material defined by its resilience, versatility, and reliability. Armed with experience, expertise, and a robust understanding of industry requirements, businesses can harness the mesh’s myriad benefits—ensuring their products not only meet but exceed the demands of tomorrow’s challenges.

Developing a deeper trust in this material hinges on understanding the rigorous testing and standards it adheres to, especially in high-stakes environments. For example, the automotive and aerospace sectors demand materials that endure stress without compromising safety. Stainless steel woven mesh meets these high standards, backed by certifications and tests that ensure it performs under pressure. From a sustainability perspective, stainless steel's recyclability bolsters its status as an eco-friendly choice among raw materials. The ability to recycle stainless steel without degrading its quality means it fits seamlessly into the circular economy model. Companies leveraging this material can simultaneously enhance their sustainability profiles while meeting industry performance standards, thus satisfying both ecological and regulatory demands. In application, knowing how to leverage the mesh’s full potential requires both experience and an in-depth understanding of your industry’s specific needs. For instance, selecting the correct mesh weave—plain, twilled, or Dutch—based on your application, is an art informed by expertise. Each weave type offers distinct advantages in filtering, sieving, and protecting, necessitating an authoritative approach to choice. Experience also plays a crucial part when integrating stainless steel woven mesh into cutting-edge technological advancements, such as in smart grid solutions and next-generation infrastructure projects. The mesh’s effectiveness in electromagnetic shielding and its contribution to enhancing the durability and performance of componentry in these high-tech fields further cements its reputation. In conclusion, stainless steel woven mesh transcends its basic functional role to represent a material defined by its resilience, versatility, and reliability. Armed with experience, expertise, and a robust understanding of industry requirements, businesses can harness the mesh’s myriad benefits—ensuring their products not only meet but exceed the demands of tomorrow’s challenges.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024