2 月 . 04, 2025 04:49

Back to list

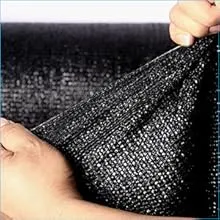

Plastic Flat Nets

The wire mesh welding machine industry is witnessing remarkable growth as more sectors recognize the benefits of investing in automated solutions. Wire mesh plays a critical role in construction, agriculture, security, and even art installations. When selecting a wire mesh welding machine manufacturer, it's essential to consider several factors that can determine the efficiency, durability, and cost-effectiveness of your investment.

Investing in a wire mesh welding machine is a significant outlay, so it's essential to consider technical support and training offerings. Manufacturers who offer comprehensive training ensure that your staff can get the best out of their machines. From initial setup to daily operations, skilled trainers help in lowering the learning curve and maintaining high productivity levels. The availability of consistent technical support can also mitigate downtime, thus protecting your investment. Advanced features in modern wire mesh welding machines include automated settings, user-friendly interfaces, and digital integration capabilities, such as IoT compatibility. Automation is a game-changer, allowing reduced labor costs and minimizing human error—a double boon for production efficiency and quality assurance. Digital integration provides real-time monitoring and diagnostics, enabling predictive maintenance that further reduces unexpected downtimes. When choosing a manufacturer for wire mesh welding machines, ideal candidates will exhibit strengths in experience, expertise, authority, and trustworthiness. Experienced manufacturers usually perform better in custom projects, offering machines that cater to specific business requirements. Expertise ensures a focus on innovation and specialization, while authority indicates a well-recognized capability backed by industry benchmarks and satisfied clients. Trustworthiness in business transactions promises transparency and reliability. Selecting the right manufacturer is about forming a long-term partnership that aligns with your business goals. Making a wise choice upfront can enhance your operational efficiencies and safeguard your investment for years to come. In a rapidly evolving industry landscape, choosing a manufacturer committed to excellence across these four pillars will help you stay ahead of the competition, ensuring both immediate and sustained success.

Investing in a wire mesh welding machine is a significant outlay, so it's essential to consider technical support and training offerings. Manufacturers who offer comprehensive training ensure that your staff can get the best out of their machines. From initial setup to daily operations, skilled trainers help in lowering the learning curve and maintaining high productivity levels. The availability of consistent technical support can also mitigate downtime, thus protecting your investment. Advanced features in modern wire mesh welding machines include automated settings, user-friendly interfaces, and digital integration capabilities, such as IoT compatibility. Automation is a game-changer, allowing reduced labor costs and minimizing human error—a double boon for production efficiency and quality assurance. Digital integration provides real-time monitoring and diagnostics, enabling predictive maintenance that further reduces unexpected downtimes. When choosing a manufacturer for wire mesh welding machines, ideal candidates will exhibit strengths in experience, expertise, authority, and trustworthiness. Experienced manufacturers usually perform better in custom projects, offering machines that cater to specific business requirements. Expertise ensures a focus on innovation and specialization, while authority indicates a well-recognized capability backed by industry benchmarks and satisfied clients. Trustworthiness in business transactions promises transparency and reliability. Selecting the right manufacturer is about forming a long-term partnership that aligns with your business goals. Making a wise choice upfront can enhance your operational efficiencies and safeguard your investment for years to come. In a rapidly evolving industry landscape, choosing a manufacturer committed to excellence across these four pillars will help you stay ahead of the competition, ensuring both immediate and sustained success.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024