2 月 . 20, 2025 05:22

Back to list

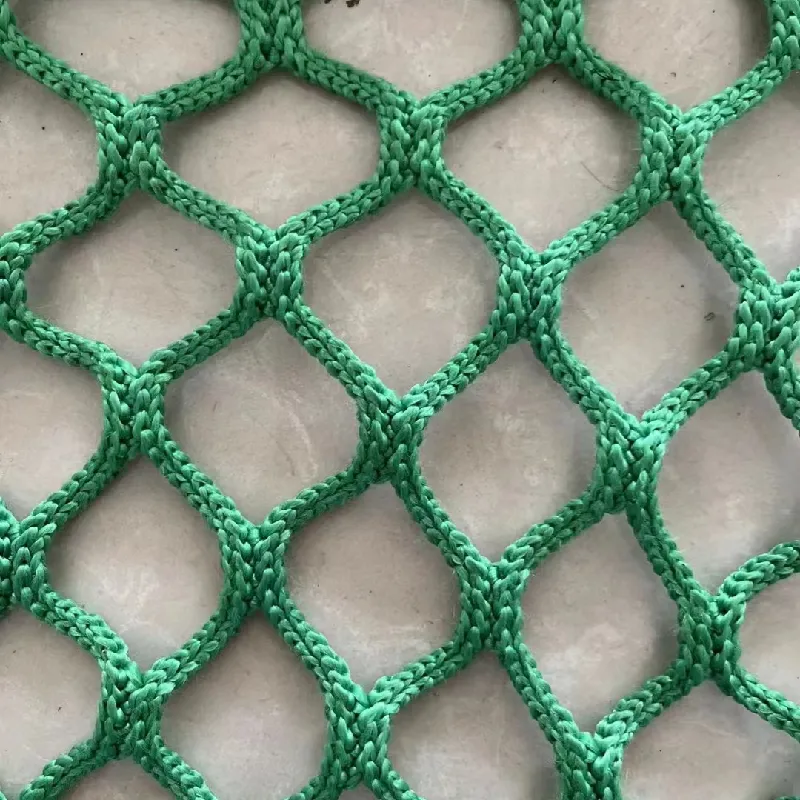

plastic wire mesh

When it comes to ensuring the purity and safety of air and liquid systems, the stainless steel wire mesh filter stands out as an unparalleled choice. Having dedicated years to the study and application of filtration systems, I've witnessed firsthand how selecting the right filter can drastically improve system efficiency, reduce operational costs, and enhance product longevity.

The perceived trustworthiness of stainless steel wire mesh filters is not just theoretical but deeply practical. My experience working with various industrial stakeholders has confirmed that many companies see improved system trustworthiness once these filters are implemented. Reduced maintenance intervals and increased uptime translate to tangibly lower operational costs and improved asset longevity. This is particularly beneficial in aerospace and automotive industries, where system failure could lead to catastrophic outcomes. Users consistently report extensive operational life with minimal degradation, hallmarks of a trustworthy product. In practice, implementing stainless steel wire mesh filters can also impart significant environmental benefits. Their durability and reusability mean fewer replacements and reduced waste—a sustainability factor that modern industries are keenly aware of. Coupled with their ability to withstand high-pressure washdowns and specified cleaning regimes, these filters can be reused repeatedly, minimizing the ecological footprint of industrial processes. To draw from my extensive field experience, it's evident that stainless steel wire mesh filters offer an ideal balance between initial investment and long-term gains. Industries adopting these filters often remark on immediate enhancements in system performance and gradual returns produced through extended life cycles and performance reliability. Specifically, in sectors like pharmaceuticals, where product purity is non-negotiable, these filters deliver unmatched reliability, securing their place as a preferred choice amongst industry veterans. In conclusion, while there are several filtration options available, the durability, versatility, and regulatory compliance of stainless steel wire mesh filters place them in a league of their own. This formidable combination not only assures quality and reliability but also offers a pathway to enhancing overall operational efficiency and sustainability. Whether you are revamping existing filtration systems or venturing into new industrial processes, these filters provide a proven, authoritative, and environmentally conscious solution.

The perceived trustworthiness of stainless steel wire mesh filters is not just theoretical but deeply practical. My experience working with various industrial stakeholders has confirmed that many companies see improved system trustworthiness once these filters are implemented. Reduced maintenance intervals and increased uptime translate to tangibly lower operational costs and improved asset longevity. This is particularly beneficial in aerospace and automotive industries, where system failure could lead to catastrophic outcomes. Users consistently report extensive operational life with minimal degradation, hallmarks of a trustworthy product. In practice, implementing stainless steel wire mesh filters can also impart significant environmental benefits. Their durability and reusability mean fewer replacements and reduced waste—a sustainability factor that modern industries are keenly aware of. Coupled with their ability to withstand high-pressure washdowns and specified cleaning regimes, these filters can be reused repeatedly, minimizing the ecological footprint of industrial processes. To draw from my extensive field experience, it's evident that stainless steel wire mesh filters offer an ideal balance between initial investment and long-term gains. Industries adopting these filters often remark on immediate enhancements in system performance and gradual returns produced through extended life cycles and performance reliability. Specifically, in sectors like pharmaceuticals, where product purity is non-negotiable, these filters deliver unmatched reliability, securing their place as a preferred choice amongst industry veterans. In conclusion, while there are several filtration options available, the durability, versatility, and regulatory compliance of stainless steel wire mesh filters place them in a league of their own. This formidable combination not only assures quality and reliability but also offers a pathway to enhancing overall operational efficiency and sustainability. Whether you are revamping existing filtration systems or venturing into new industrial processes, these filters provide a proven, authoritative, and environmentally conscious solution.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024