2 月 . 20, 2025 04:54

Back to list

fine nylon mesh

Navigating the world of filtration and sieving, fine stainless steel mesh screens have emerged as an indispensable component across a variety of industries, offering superior durability and precision. Through personal experiences and industry insights, the unique properties of fine stainless steel mesh screens and their multifaceted applications can be better understood, alongside their advantages that make these screens a top choice for professionals seeking reliable solutions for complex tasks.

Trustworthiness is another domain where fine stainless steel mesh screens excel. Businesses that invest in high-quality mesh screens often do so with the understanding that these products are tested and certified to meet international quality standards. The confidence provided by such certifications - ISO, ASTM, and others - lends credibility to their use in critical applications where failure could result in significant financial or environmental repercussions. During a visit to a mining operation, a project manager expressed immense satisfaction with their choice of certified stainless steel mesh screens, emphasizing the minimal downtime and consistent performance as key benefits. Additionally, fine stainless steel mesh screens are part of sustainable practices adopted by industries aiming to reduce their environmental footprint. Being entirely recyclable, stainless steel mesh is not just a temporary solution but part of a long-term strategy to conserve resources and promote eco-friendly initiatives. This aspect has gained increasing attention, especially in sectors under scrutiny for their environmental impact. An industrial facility shared how their transition to stainless steel mesh screens was motivated not just by performance metrics, but by corporate responsibility towards sustainable operations. In conclusion, the use of fine stainless steel mesh screens transcends simple filtration needs. Combining real-world experience with professional expertise, it becomes clear that these screens embody resilience, safety, efficiency, and environmental stewardship. For those in the market looking for a trustworthy, tried-and-true solution, stainless steel mesh screens present a compelling case rooted in a legacy of dependability and precision. Whether it’s ensuring contaminants are filtered from food, enhancing water purity, or actively contributing to environmental conservation, fine stainless steel mesh screens offer unparalleled benefits that stand as a testament to their continued relevance and importance in modern industry.

Trustworthiness is another domain where fine stainless steel mesh screens excel. Businesses that invest in high-quality mesh screens often do so with the understanding that these products are tested and certified to meet international quality standards. The confidence provided by such certifications - ISO, ASTM, and others - lends credibility to their use in critical applications where failure could result in significant financial or environmental repercussions. During a visit to a mining operation, a project manager expressed immense satisfaction with their choice of certified stainless steel mesh screens, emphasizing the minimal downtime and consistent performance as key benefits. Additionally, fine stainless steel mesh screens are part of sustainable practices adopted by industries aiming to reduce their environmental footprint. Being entirely recyclable, stainless steel mesh is not just a temporary solution but part of a long-term strategy to conserve resources and promote eco-friendly initiatives. This aspect has gained increasing attention, especially in sectors under scrutiny for their environmental impact. An industrial facility shared how their transition to stainless steel mesh screens was motivated not just by performance metrics, but by corporate responsibility towards sustainable operations. In conclusion, the use of fine stainless steel mesh screens transcends simple filtration needs. Combining real-world experience with professional expertise, it becomes clear that these screens embody resilience, safety, efficiency, and environmental stewardship. For those in the market looking for a trustworthy, tried-and-true solution, stainless steel mesh screens present a compelling case rooted in a legacy of dependability and precision. Whether it’s ensuring contaminants are filtered from food, enhancing water purity, or actively contributing to environmental conservation, fine stainless steel mesh screens offer unparalleled benefits that stand as a testament to their continued relevance and importance in modern industry.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

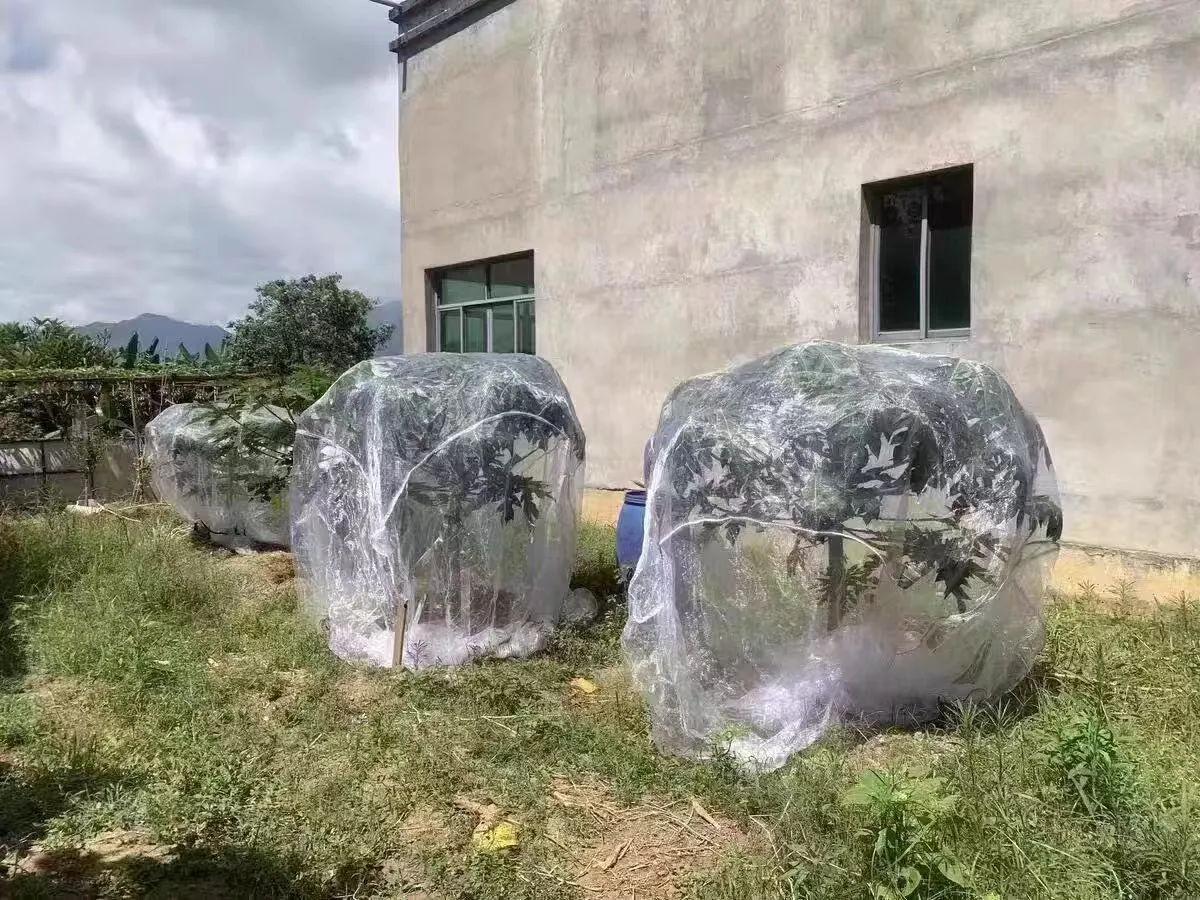

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024