2 月 . 20, 2025 04:17

Back to list

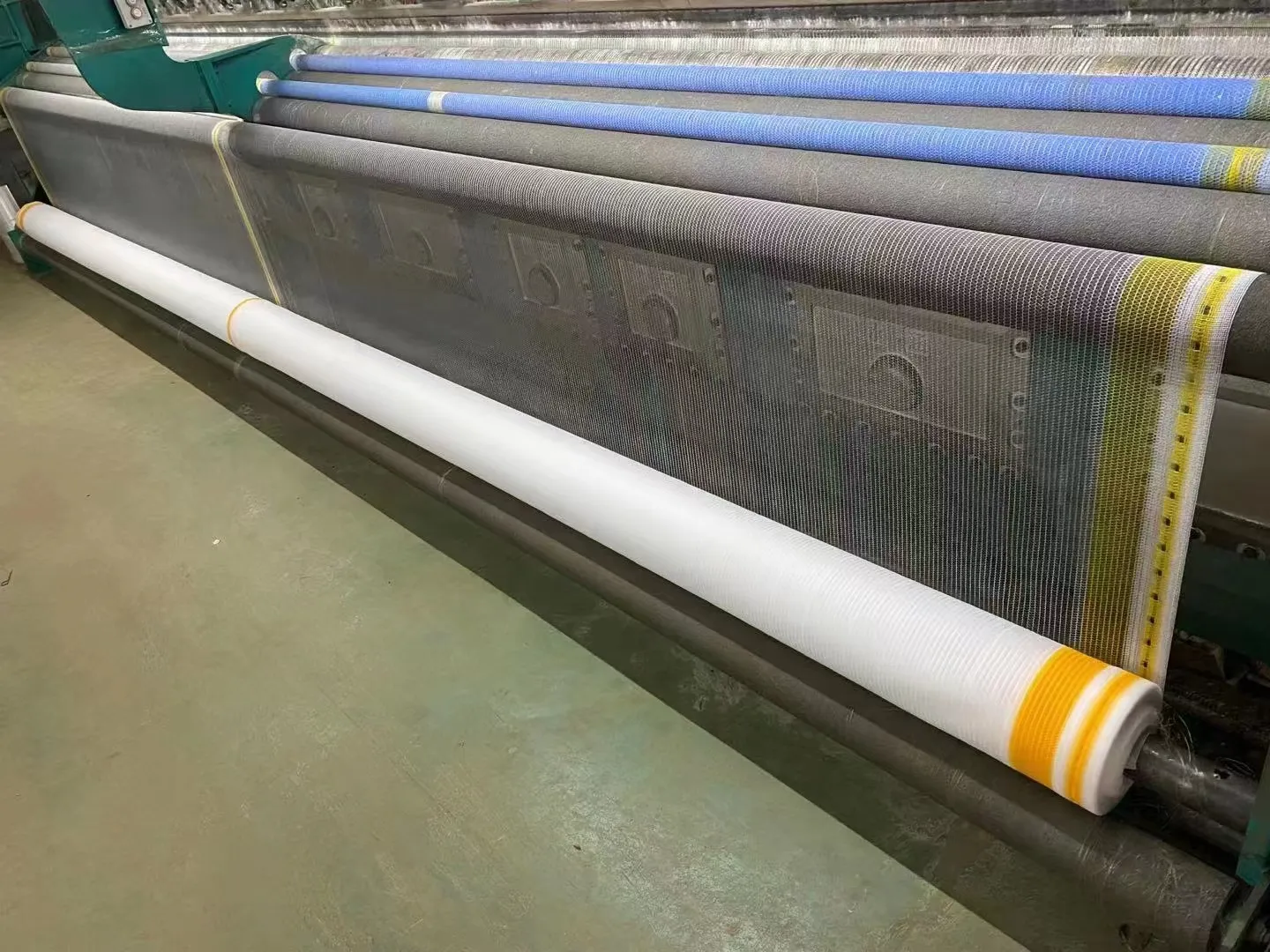

filter nylon mesh

When introduced to industrial filtration, steel filter mesh emerges as an unsung hero celebrated for its robustness, versatility, and reliability. Accustomed to environments demanding supreme strength and precision, steel filter mesh is often the backbone of countless filtration applications worldwide. This article explores its influential presence, performance, and the reasons why it remains a preferred choice for industries demanding high technical standards.

Expertise in handling and installing steel filter mesh involves understanding the delicate balance between mesh strength and flexibility. Technician training emphasizes the importance of correct installation procedures and regular maintenance schedules to optimize performance. The growing literature on industrial safety also reinforces the integrity of steel filter mesh systems, as they often contribute significantly to plant safety by ensuring contaminants are continuously and effectively removed from critical processes. As the industrial landscape progresses toward more sustainable practices, the recyclability of steel filter mesh further aligns with eco-friendly paradigms. Steel, known for its recyclable characteristics without degradation, ensures that companies can incorporate more sustainable practices without compromising on operational efficiency. In conclusion, steel filter mesh occupies a pivotal role in modern industry as a symbol of trust and authority. Its benefits are recognized not just from a performance perspective, but also from an economic and environmental standpoint. Professionals crafting, selecting, and implementing these meshes are charged with supporting industries that rely on uncompromised purity and filtration excellence. The success stories from industries using steel filter meshes speak volumes of its capability to provide precise filtration solutions, fortifying its status as the preferred choice in high-stakes applications. As industrial needs evolve, steel filter mesh is expected to lead in innovation, reliability, and sustainable practices.

Expertise in handling and installing steel filter mesh involves understanding the delicate balance between mesh strength and flexibility. Technician training emphasizes the importance of correct installation procedures and regular maintenance schedules to optimize performance. The growing literature on industrial safety also reinforces the integrity of steel filter mesh systems, as they often contribute significantly to plant safety by ensuring contaminants are continuously and effectively removed from critical processes. As the industrial landscape progresses toward more sustainable practices, the recyclability of steel filter mesh further aligns with eco-friendly paradigms. Steel, known for its recyclable characteristics without degradation, ensures that companies can incorporate more sustainable practices without compromising on operational efficiency. In conclusion, steel filter mesh occupies a pivotal role in modern industry as a symbol of trust and authority. Its benefits are recognized not just from a performance perspective, but also from an economic and environmental standpoint. Professionals crafting, selecting, and implementing these meshes are charged with supporting industries that rely on uncompromised purity and filtration excellence. The success stories from industries using steel filter meshes speak volumes of its capability to provide precise filtration solutions, fortifying its status as the preferred choice in high-stakes applications. As industrial needs evolve, steel filter mesh is expected to lead in innovation, reliability, and sustainable practices.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024