3 月 . 04, 2025 08:58

Back to list

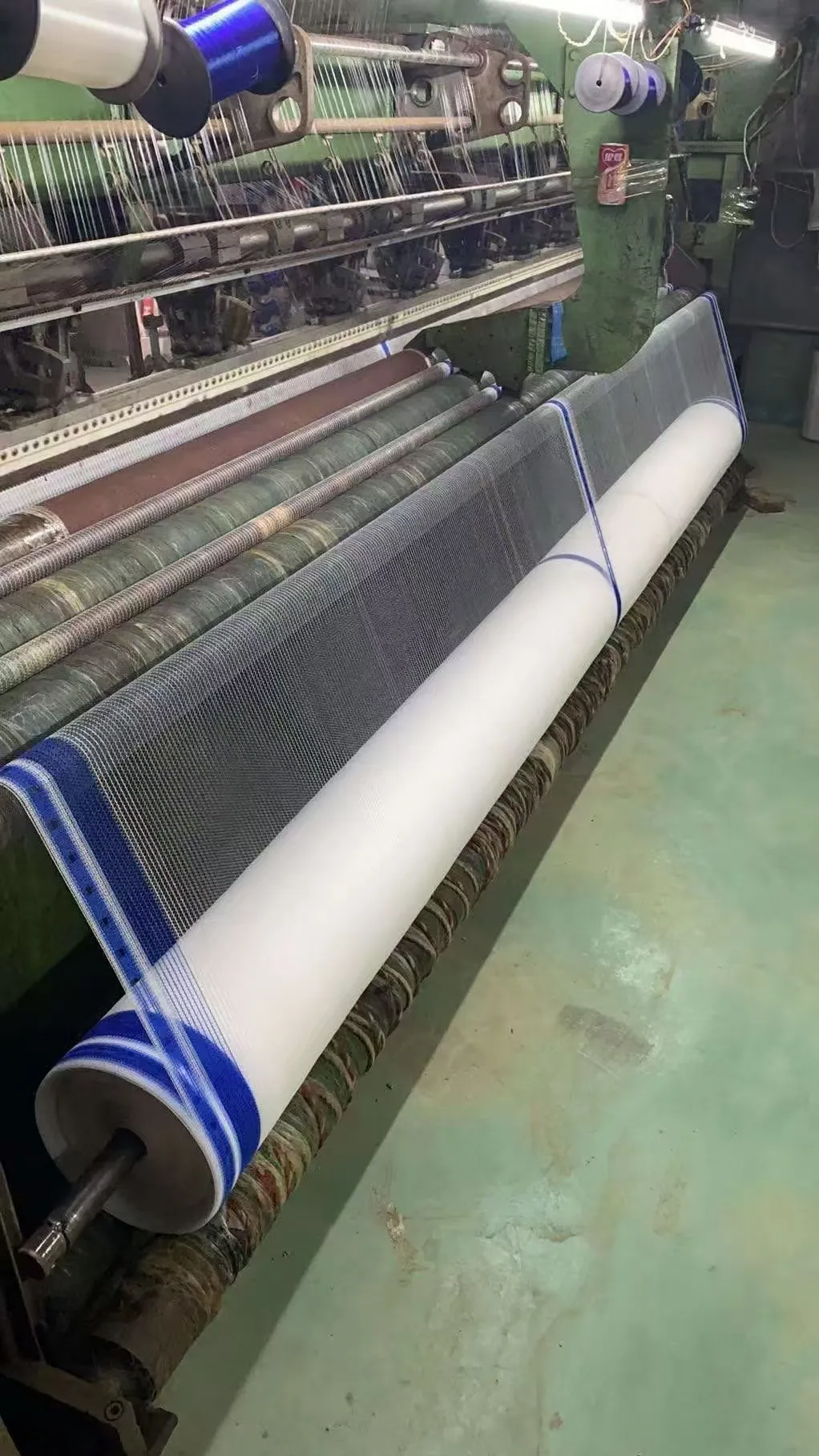

nylon mesh screen

Mining screen mesh is a pivotal component within the mining industry and serves as an essential tool in managing material separation processes. With years of collective industry experience, this article delves deeply into the utilization, benefits, and technical aspects that make mining screen mesh an invaluable asset to mining operations.

Screen meshes contribute significantly to sustainable mining practices. By ensuring efficient separation and reducing wastage, they play a pivotal role in minimizing environmental impact. Innovations such as recycled or recyclable materials, combined with technological upgrades, embody the industry's shift towards more environmentally-conscious operations. Mining professionals worldwide consistently praise the adaptability and functionality of modern screen mesh technologies. Real-world applications showcase how tailored solutions directly correlate with measurable improvements in efficiency and output. Consider a coal mine operation that incorporated customized screen meshes and reported a marked reduction in maintenance costs due to the mesh's enhanced durability. With competition mounting and regulations tightening within the mining industry, it becomes increasingly vital for decision-makers to rely on expertly crafted, authoritative resources like this article to guide their selection of mining screen mesh solutions. Industry experts predict that future advancements will revolve around AI-driven predictive maintenance and smart materials designed to further enhance operational efficiency. Stakeholders would be wise to keep abreast of emerging trends and innovations, ensuring their operations remain at the forefront of mining technology. In conclusion, mining screen mesh is not merely a tool but a strategic component that determines operational success. Its role in enhancing efficiency, coupled with its adaptability to diverse mining conditions, reinforces its importance as a cornerstone of effective mining strategies. Stakeholders are encouraged to prioritize experience, expertise, and trustworthiness in their partnerships, to fortify their operations against the challenges and opportunities presented by the fast-evolving mining landscape.

Screen meshes contribute significantly to sustainable mining practices. By ensuring efficient separation and reducing wastage, they play a pivotal role in minimizing environmental impact. Innovations such as recycled or recyclable materials, combined with technological upgrades, embody the industry's shift towards more environmentally-conscious operations. Mining professionals worldwide consistently praise the adaptability and functionality of modern screen mesh technologies. Real-world applications showcase how tailored solutions directly correlate with measurable improvements in efficiency and output. Consider a coal mine operation that incorporated customized screen meshes and reported a marked reduction in maintenance costs due to the mesh's enhanced durability. With competition mounting and regulations tightening within the mining industry, it becomes increasingly vital for decision-makers to rely on expertly crafted, authoritative resources like this article to guide their selection of mining screen mesh solutions. Industry experts predict that future advancements will revolve around AI-driven predictive maintenance and smart materials designed to further enhance operational efficiency. Stakeholders would be wise to keep abreast of emerging trends and innovations, ensuring their operations remain at the forefront of mining technology. In conclusion, mining screen mesh is not merely a tool but a strategic component that determines operational success. Its role in enhancing efficiency, coupled with its adaptability to diverse mining conditions, reinforces its importance as a cornerstone of effective mining strategies. Stakeholders are encouraged to prioritize experience, expertise, and trustworthiness in their partnerships, to fortify their operations against the challenges and opportunities presented by the fast-evolving mining landscape.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024