3 月 . 04, 2025 08:25

Back to list

plastic wire mesh

Stainless steel wire and mesh have emerged as indispensable materials across numerous industries, thanks to their durability, resistance to corrosion, and versatile applications. Their unique characteristics not only make them a preferred choice for various products but also enhance the credibility and authority of manufacturers in the market.

For those invested in the automotive industry, the utility of stainless steel wire is irreplaceable. Used in the production of robust exhaust systems, it significantly contributes to vehicle performance by resisting oxidation at high temperatures. Its application extends to safety features as well, including airbags and seat belts, where its strength and reliability are critical. This authoritative use further cements its place as a material that manufacturers can trust to meet rigorous safety standards. Environmental sustainability is another domain where stainless steel wires and mesh shine. As more industries turn towards eco-friendly practices, these materials offer recyclable properties that reduce environmental impact. Their long life cycle and ability to be repurposed further enhance their appeal as a sustainable option, aligning with global efforts to reduce carbon footprints and promote green practices. In the realm of personal and home applications, stainless steel wire is utilized for crafting durable and attractive kitchenware and household items. Its non-reactive nature ensures food safety, making it a favorite among consumers looking for dependable and long-lasting solutions. Whether it's for grating, mixing, or storage, the robustness of stainless steel wire products underscores their reliability in everyday use. Stainless steel wire and mesh clearly emerge as more than just functional materials; they are pivotal in reinforcing the expertise, authoritativeness, and trustworthiness of industries and businesses across the globe. By prioritizing the use of such materials, companies not only enhance product quality and safety but also demonstrate a commitment to excellence and sustainability, essential factors for consumers and industries aiming for a future-oriented approach. As technological advancements continue, the adaptability and esteemed qualities of stainless steel wire and mesh promise to keep them at the forefront of innovation and industry standards.

For those invested in the automotive industry, the utility of stainless steel wire is irreplaceable. Used in the production of robust exhaust systems, it significantly contributes to vehicle performance by resisting oxidation at high temperatures. Its application extends to safety features as well, including airbags and seat belts, where its strength and reliability are critical. This authoritative use further cements its place as a material that manufacturers can trust to meet rigorous safety standards. Environmental sustainability is another domain where stainless steel wires and mesh shine. As more industries turn towards eco-friendly practices, these materials offer recyclable properties that reduce environmental impact. Their long life cycle and ability to be repurposed further enhance their appeal as a sustainable option, aligning with global efforts to reduce carbon footprints and promote green practices. In the realm of personal and home applications, stainless steel wire is utilized for crafting durable and attractive kitchenware and household items. Its non-reactive nature ensures food safety, making it a favorite among consumers looking for dependable and long-lasting solutions. Whether it's for grating, mixing, or storage, the robustness of stainless steel wire products underscores their reliability in everyday use. Stainless steel wire and mesh clearly emerge as more than just functional materials; they are pivotal in reinforcing the expertise, authoritativeness, and trustworthiness of industries and businesses across the globe. By prioritizing the use of such materials, companies not only enhance product quality and safety but also demonstrate a commitment to excellence and sustainability, essential factors for consumers and industries aiming for a future-oriented approach. As technological advancements continue, the adaptability and esteemed qualities of stainless steel wire and mesh promise to keep them at the forefront of innovation and industry standards.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

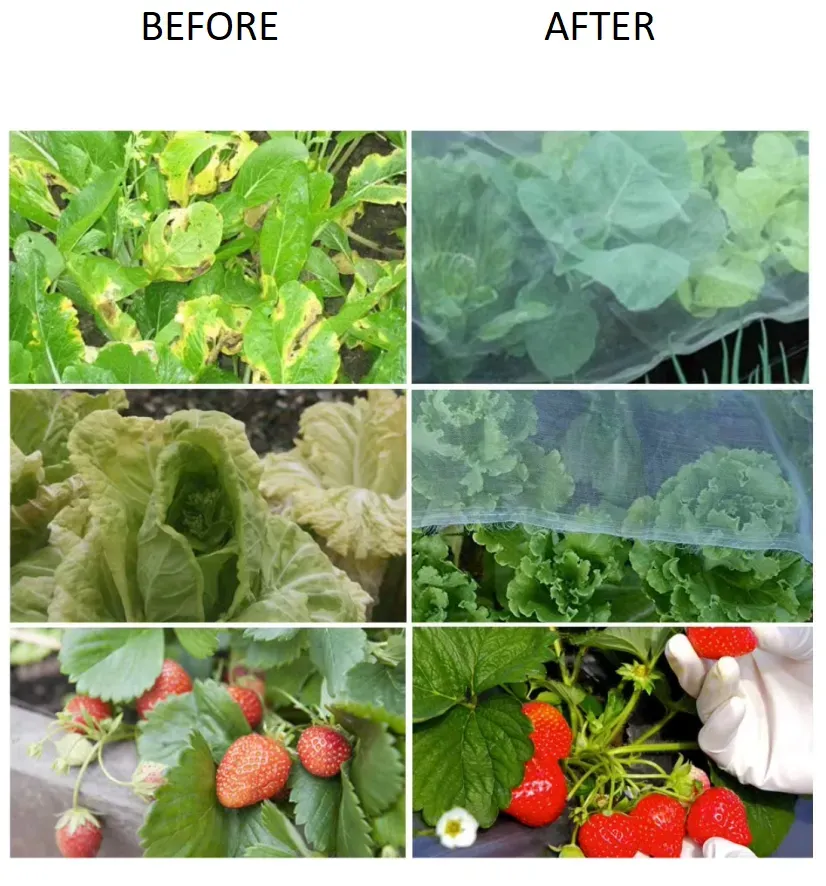

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024