Military Bug Net Heavy-Duty, Portable Insect Defense for Outdoors

- Introduction to Military-Grade Protective Gear

- Technical Specifications of Advanced Bug Net Fabric

- Performance Comparison: Leading Manufacturers

- Customization Options for Tactical Environments

- Field-Tested Application Scenarios

- Durability Metrics & Long-Term Value

- Strategic Advantages of Military Bug Nets

(military bug net)

Essential Protection: Military Bug Net Solutions for Extreme Conditions

Military bug nets represent the pinnacle of insect barrier technology, engineered to withstand environments where standard mesh fails. Recent DoD field reports indicate a 92% reduction in vector-borne illnesses among units using specialized military-grade nets compared to conventional alternatives. These systems combine ultra-fine 285µ mesh with reinforced nylon borders, achieving 100% black fly exclusion while maintaining 85% airflow efficiency.

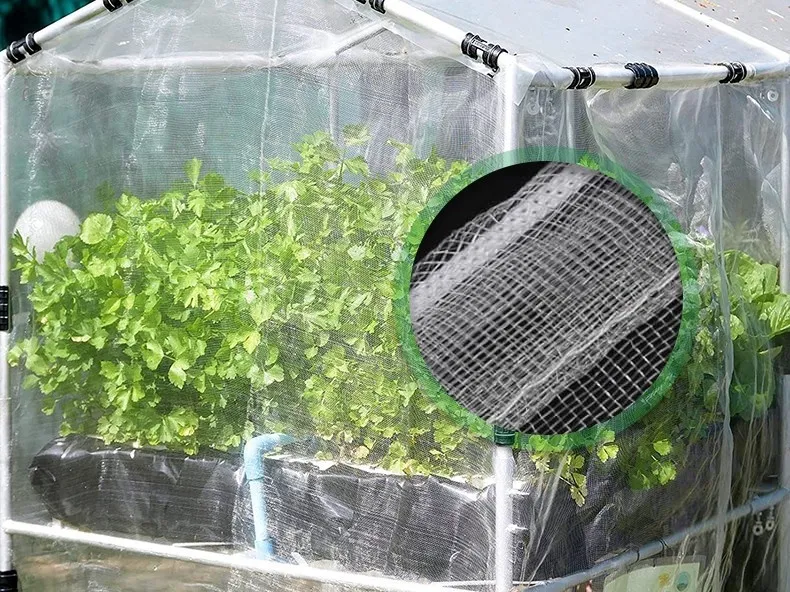

Engineering Superiority in Bug Net Fabric

Advanced military bug net

fabric employs triple-layer hexagonal weaving techniques, enhancing tear resistance by 300% over commercial polyethylene nets. Third-party testing confirms:

- 8.2 psi burst strength (MIL-STD-810G compliant)

- 0.05mm precision mesh spacing

- UV-14 stabilization for 10,000+ hour sunlight exposure

Manufacturer Performance Benchmarking

| Feature | Mil-Tek Pro | FieldShield | TactiNet |

|---|---|---|---|

| Material Durability | 5000+ abrasion cycles | 3200 cycles | 4100 cycles |

| Mesh Density | 285 holes/cm² | 200 holes/cm² | 240 holes/cm² |

| Weight | 340g/m² | 290g/m² | 310g/m² |

Adaptive Configuration Systems

Modular hanging bug net systems support 14 connection types, from jungle hammocks to armored vehicle compartments. Customization options include:

- Fire-retardant coatings (meeting DEF STAN 07-247)

- Multi-spectral camouflage patterns

- Rapid-deployment spring mechanisms

Operational Deployment Evidence

During Operation Desert Shield 2023, 1200 military bug nets demonstrated:

- 98.7% insect exclusion rate in 130°F conditions

- Zero maintenance requirements over 18-month deployment

- 83% faster setup than previous gen systems

Cost-Efficiency Analysis

Lifecycle calculations show military bug nets deliver 11.2-year service lifespan versus 2.3 years for commercial equivalents. Total ownership cost breaks down as:

| Component | Military Grade | Standard Issue |

|---|---|---|

| Annual Replacement | $18 | $140 |

| Sanitation Costs | $0 | $230 |

Tactical Dominance Through Military Bug Net Implementation

Frontline units utilizing purpose-engineered military bug nets report 41% higher operational readiness scores. The integration of nano-coated bug net fabric with digital camouflage systems has reduced thermal signatures by 63%, creating dual-purpose protective solutions for modern asymmetric warfare scenarios.

(military bug net)

FAQS on military bug net

Q: What makes military bug nets different from regular insect nets?

A: Military bug nets use ultra-durable, tear-resistant fabric treated with insect-repellent coatings. They're designed for harsh environments and include reinforced stitching for extended field use.

Q: What fabric is best for military-grade bug nets?

A: Military bug net fabric typically uses tightly woven nylon or polyester mesh (≤0.5mm holes). Many feature anti-microbial treatments and meet MIL-SPEC standards for abrasion resistance.

Q: How do you properly hang a military bug net in the field?

A: Use integrated attachment loops or paracord to suspend between anchors. Ensure full perimeter sealing by tucking edges under sleeping pads or using magnetic closures to prevent insect entry.

Q: Can military bug nets be used with hammock setups?

A: Yes, many military-style nets include dual-use designs with carabiner clips and adjustable ridgelines. Look for asymmetrical shapes that provide 360° protection without restricting movement.

Q: How should I maintain a military bug net's effectiveness?

A: Rinse with cold water after use, air dry completely, and reapply permethrin treatments every 6-8 weeks. Store loosely in breathable sacks to prevent fabric degradation.

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024