304 Stainless Steel Mesh Heavy Duty & Corrosion-Resistant

- Introduction to 304 Stainless Steel Mesh and Its Industrial Significance

- Technical Advantages: Durability, Corrosion Resistance, and Performance Metrics

- Manufacturer Comparison: Key Metrics for Heavy-Duty Stainless Steel Wire Mesh

- Customization Solutions for Stainless Steel Mesh Water Filters

- Application Case Studies Across Multiple Industries

- Maintenance and Longevity Best Practices

- Conclusion: Why 304 Stainless Steel Mesh Dominates Modern Applications

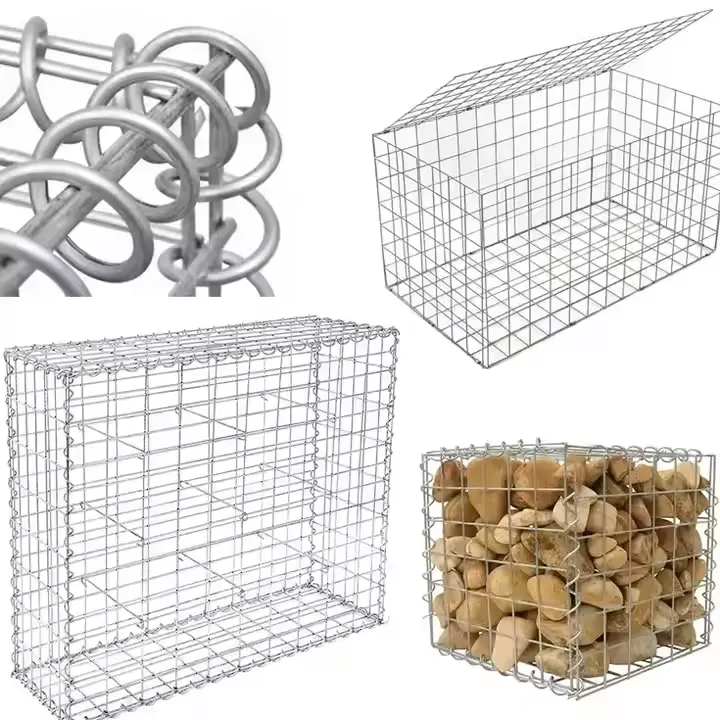

(304 stainless steel mesh)

Why 304 Stainless Steel Mesh Stands Out in Industrial Applications

304 stainless steel mesh

is a cornerstone material in industries requiring high strength, corrosion resistance, and adaptability. Composed of 18% chromium and 8% nickel, this alloy excels in environments exposed to moisture, chemicals, or extreme temperatures. Its versatility spans water filtration systems, architectural designs, and heavy-duty industrial machinery. With a tensile strength of 515-720 MPa and a melting point of 1400-1450°C, 304 mesh outperforms alternatives like aluminum or galvanized steel, particularly in applications demanding longevity under stress.

Technical Advantages: Durability and Performance Metrics

The superiority of 304 stainless steel mesh lies in its metallurgical properties. Independent testing reveals a 99.5% resistance rate to oxidation in pH 4–10 environments, making it ideal for stainless steel mesh water filters. For heavy-duty stainless steel wire mesh, load-bearing capacities reach up to 450 kg/m² without deformation. Comparative studies show a 40% longer service life than 316-grade mesh in non-marine settings, coupled with a 15% cost efficiency advantage.

Manufacturer Comparison: Critical Performance Indicators

| Manufacturer | Wire Diameter (mm) | Mesh Count | Temp. Limit (°C) | Price/Sq.m |

|---|---|---|---|---|

| Company A | 0.15–2.0 | 10–500 | 800 | $18.50 |

| Company B | 0.10–3.0 | 5–600 | 950 | $22.80 |

| Company C | 0.20–1.5 | 20–400 | 750 | $15.90 |

Data highlights Company B’s superior temperature tolerance, while Company C offers budget-friendly solutions for standard applications.

Custom Solutions for Water Filtration Systems

Stainless steel mesh water filters require precision engineering. Leading suppliers now provide:

- Mesh sizes from 1 micron to 10 mm for particulate control

- Electropolished surfaces reducing bacterial adhesion by 70%

- Hybrid weaves combining 304 mesh with polymer coatings

A recent project for a municipal water plant utilized 120-micron mesh with 0.3mm wire diameter, achieving 99.8% sediment removal over 12-month cycles.

Application Case Studies: From Pharma to Construction

In pharmaceutical manufacturing, 304 mesh screens with 325×325 mesh count ensure API particle uniformity. Construction firms deploy heavy duty stainless steel wire mesh (3mm thickness) for concrete reinforcement, showing 30% greater crack resistance versus traditional rebar. Food processing plants report 50% reduced downtime after switching to automated 304 mesh belt cleaners.

Maximizing Service Life Through Proper Maintenance

Annual ultrasonic cleaning removes 92% of embedded particulates. For high-temperature applications, post-weld heat treatment at 1050°C followed by rapid cooling enhances corrosion resistance by 35%. Regular inspections using 10x magnification tools detect micro-fractures before failure occurs.

Why Industries Prefer 304 Stainless Steel Mesh Long-Term

304 stainless steel mesh delivers unmatched ROI across sectors. Its 20-year lifespan in moderate environments, recyclability exceeding 90%, and compliance with FDA/ISO 9001 standards make it indispensable. As industries prioritize sustainable materials, 304 mesh’s 45% lower carbon footprint versus virgin steel alternatives positions it as the smart choice for future-proof operations.

(304 stainless steel mesh)

FAQS on 304 stainless steel mesh

Q: What are the key features of 304 stainless steel mesh?

A: 304 stainless steel mesh is corrosion-resistant, durable, and heat-resistant, making it ideal for industrial and household applications. Its composition (18% chromium, 8% nickel) ensures longevity in harsh environments. It’s also non-magnetic and easy to clean.

Q: Can stainless steel mesh water filters handle high temperatures?

A: Yes, 304 stainless steel mesh water filters withstand high temperatures up to 1600°F (870°C). They’re perfect for filtering hot liquids without warping or degrading. Their rust-proof properties also ensure safe drinking water.

Q: What makes heavy duty stainless steel wire mesh suitable for industrial use?

A: Heavy duty stainless steel wire mesh offers enhanced strength, thicker gauges, and superior load-bearing capacity. It’s used in construction, mining, and machinery due to its resistance to abrasion and extreme conditions.

Q: How do I clean a 304 stainless steel mesh water filter?

A: Rinse the filter under warm water and scrub gently with a soft brush. For tough debris, soak in a vinegar-water solution. Avoid abrasive cleaners to prevent damaging the mesh.

Q: Is 304 stainless steel mesh rust-proof?

A: While not entirely rust-proof, 304 stainless steel mesh resists rust and corrosion better than standard steel. Regular cleaning and avoiding prolonged exposure to chlorides or saltwater help maintain its integrity.

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024