1 月 . 24, 2025 03:05

Back to list

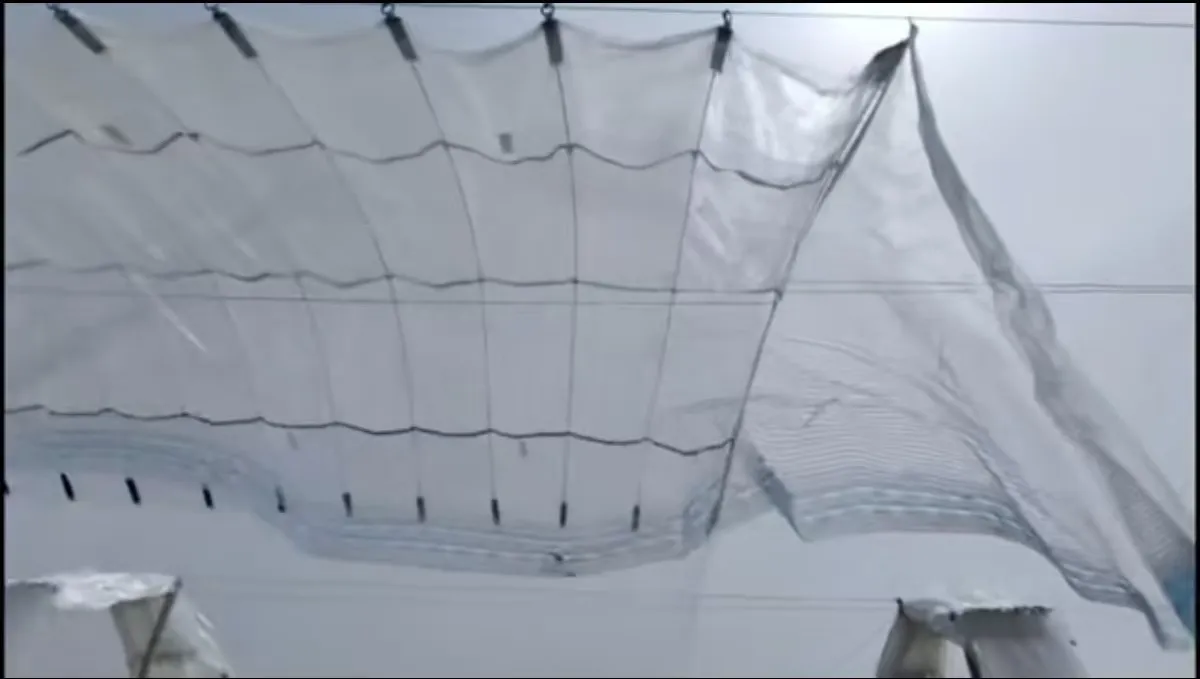

solar bird mesh

Expanded stainless steel mesh is revolutionizing industries with its unparalleled blend of strength, flexibility, and durability. Having traversed its evolution from industrial uses to contemporary architectural applications, it's time to explore this material's invaluable contributions to modern design and engineering.

Trustworthiness is deeply anchored in the proven track record of expanded stainless steel mesh. Clients across industries trust this material not just for its performance but also for the substantial return on investment it promises. Its minimal maintenance needs, coupled with a long life span, result in decreased operational costs over time. Testimonials from industry experts emphasize the peace of mind afforded by its reliability and cost-effectiveness. The design potential of expanded stainless steel mesh is boundless. Architects and designers leverage its transparency and texture to create dynamic spaces that interact harmoniously with light and shadows. This material enables innovative designs that were once deemed too challenging to realize due to physical and cost constraints. For instance, the intricate patterns and structures made possible by the mesh have revitalized spaces, making them visually engaging yet sustainably functional. While the expanded stainless steel mesh has become a staple in several industries, continual research and development are crucial for discovering new applications and enhancing existing ones. This involves studying and optimizing various parameters like mesh thickness, strand width, and aperture size to tailor the mesh for specific uses, ensuring it meets evolving industry demands. In conclusion, expanded stainless steel mesh is far more than a construction material; it is a testament to modern engineering's capabilities. It brings together tradition and innovation, proving indispensable in applications where resilience meets aesthetics. Whether it’s offering an overhaul in architectural design or serving as a linchpin in automotive performance, its impact is undeniably significant and enduring. This profound understanding of expanded stainless steel mesh underlines the importance of selecting this material for projects that require not just resilience but also an element of sophistication and eco-consciousness. As industries continue to evolve, the role of this material is expected to expand, forging new path as an extraordinary solution crafted for the modern world.

Trustworthiness is deeply anchored in the proven track record of expanded stainless steel mesh. Clients across industries trust this material not just for its performance but also for the substantial return on investment it promises. Its minimal maintenance needs, coupled with a long life span, result in decreased operational costs over time. Testimonials from industry experts emphasize the peace of mind afforded by its reliability and cost-effectiveness. The design potential of expanded stainless steel mesh is boundless. Architects and designers leverage its transparency and texture to create dynamic spaces that interact harmoniously with light and shadows. This material enables innovative designs that were once deemed too challenging to realize due to physical and cost constraints. For instance, the intricate patterns and structures made possible by the mesh have revitalized spaces, making them visually engaging yet sustainably functional. While the expanded stainless steel mesh has become a staple in several industries, continual research and development are crucial for discovering new applications and enhancing existing ones. This involves studying and optimizing various parameters like mesh thickness, strand width, and aperture size to tailor the mesh for specific uses, ensuring it meets evolving industry demands. In conclusion, expanded stainless steel mesh is far more than a construction material; it is a testament to modern engineering's capabilities. It brings together tradition and innovation, proving indispensable in applications where resilience meets aesthetics. Whether it’s offering an overhaul in architectural design or serving as a linchpin in automotive performance, its impact is undeniably significant and enduring. This profound understanding of expanded stainless steel mesh underlines the importance of selecting this material for projects that require not just resilience but also an element of sophistication and eco-consciousness. As industries continue to evolve, the role of this material is expected to expand, forging new path as an extraordinary solution crafted for the modern world.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024