1 月 . 24, 2025 02:43

Back to list

solar bird mesh

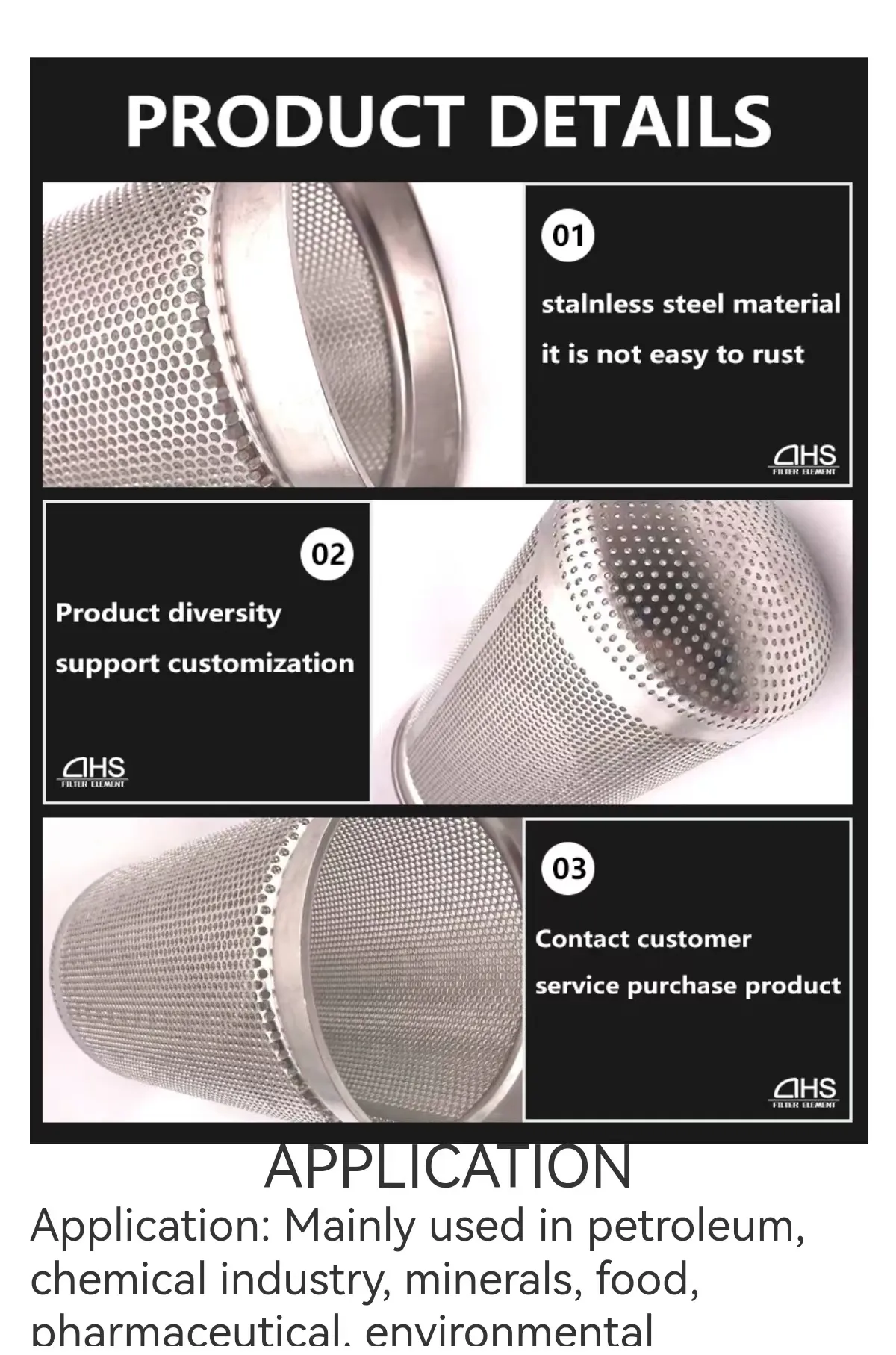

Perforated steel mesh has become increasingly significant in various industries, robustly merging functionality with aesthetic appeal. This uniquely versatile product, composed of steel sheets punched with precise holes, provides unique solutions across multiple applications. Below, we delve into the experiences, expertise, authoritativeness, and trustworthiness that underscore the value of perforated steel mesh.

Trustworthiness is another pillar firmly associated with perforated steel mesh, as demonstrated by its diverse applications in challenging environments. For instance, in chemical processing plants, the mesh is employed to create protective layers that withstand harsh chemicals and extreme temperatures, verifying its enduring resilience and reliability. The product's lifecycle can be extensive, withstanding wear in harsh outdoor or industrial conditions without significant deterioration—important factors that reflect its reliability. Moreover, sustainable production processes are increasingly becoming integral to how perforated steel mesh is sourced. Many manufacturers commit to reducing their carbon footprint by utilizing recycled steel, adhering to eco-friendly practices that further bolster the trust consumers place in this product. This aligns perforated steel mesh with growing industrial and consumer demands for sustainable solutions. In conclusion, perforated steel mesh stands out due to its unrivaled versatility, technical sophistication, and established reputation across various markets. Whether enhancing modern architectural projects or optimizing industrial operations, this strong yet flexible material continues to be a cornerstone due to its proven performance and ever-expanding applications. Therefore, for anyone considering incorporating this material into their projects, rest assured that it is a time-tested, reliable partner—offering innovation, efficiency, and sustainability.

Trustworthiness is another pillar firmly associated with perforated steel mesh, as demonstrated by its diverse applications in challenging environments. For instance, in chemical processing plants, the mesh is employed to create protective layers that withstand harsh chemicals and extreme temperatures, verifying its enduring resilience and reliability. The product's lifecycle can be extensive, withstanding wear in harsh outdoor or industrial conditions without significant deterioration—important factors that reflect its reliability. Moreover, sustainable production processes are increasingly becoming integral to how perforated steel mesh is sourced. Many manufacturers commit to reducing their carbon footprint by utilizing recycled steel, adhering to eco-friendly practices that further bolster the trust consumers place in this product. This aligns perforated steel mesh with growing industrial and consumer demands for sustainable solutions. In conclusion, perforated steel mesh stands out due to its unrivaled versatility, technical sophistication, and established reputation across various markets. Whether enhancing modern architectural projects or optimizing industrial operations, this strong yet flexible material continues to be a cornerstone due to its proven performance and ever-expanding applications. Therefore, for anyone considering incorporating this material into their projects, rest assured that it is a time-tested, reliable partner—offering innovation, efficiency, and sustainability.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024