2 月 . 10, 2025 10:24

Back to list

Thickened Nylon Mesh

When it comes to precision filtration and ensuring that the smallest particulates are captured, a 500 micron nylon mesh stands out as an indispensable tool. Renowned for its strength and versatility, nylon mesh offers a combination of durability and adaptability, making it a preferred choice across various industries including medical, pharmaceutical, food processing, and aquaculture. This article delves into the unique characteristics of 500 micron nylon mesh, supported by real-world experiences, expert insights, and authoritative evaluations to offer a comprehensive understanding of its applications and benefits.

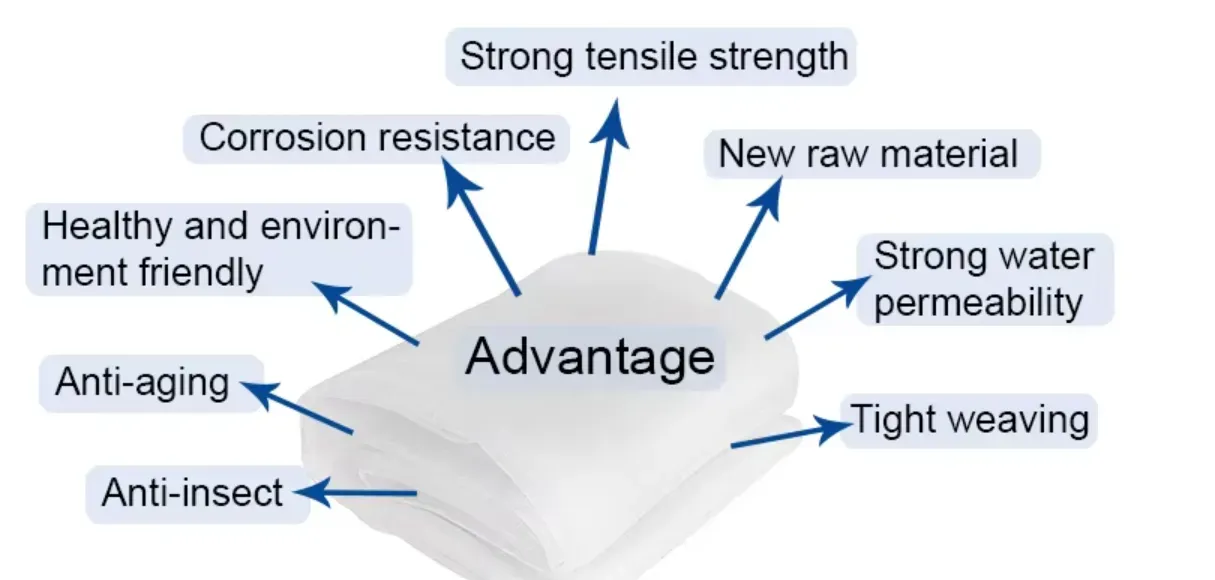

The versatility of 500 micron nylon mesh expands further into industrial and domestic settings. Engineers, scientists, and hobbyists appreciate its adaptability in projects ranging from automotive filtration systems to DIY home improvements. Its ease of handling and customization options enable it to fit specialized applications, much appreciated by those who seek tailored solutions in their respective fields. Experience shows that maintenance and longevity of 500 micron nylon mesh are crucial considerations. Users report that its inherent properties, such as resistance to environmental wear and tear, translate to longevity even in harsh conditions. With proper care, including periodic cleaning to remove accumulated particulates, the mesh can serve effectively for extended periods without compromising its integrity. Recent advances in nylon manufacturing technology have further augmented the capabilities of 500 micron mesh. Enhanced weaving techniques have improved its tensile strength, ensuring that it remains invulnerable to stretching or tearing under pressure, thereby increasing user confidence. Moreover, the availability of customizable sizes and shapes means that specific task requirements can be met with precision, supporting innovation and creativity in engineering and design endeavors. In conclusion, the 500 micron nylon mesh continues to maintain its authoritative stance across multiple sectors, providing solutions that marry efficacy with cost-efficiency. Its role is ever-expanding, driven by continuous innovation and user feedback. Thanks to its unparalleled strength, versatility, and credible track record, it remains a trusted component for professionals and enthusiasts striving for excellence in their fields. Whether employed in heavy-duty industrial applications or fine dining establishments, its contribution to operational optimization is both recognized and celebrated.

The versatility of 500 micron nylon mesh expands further into industrial and domestic settings. Engineers, scientists, and hobbyists appreciate its adaptability in projects ranging from automotive filtration systems to DIY home improvements. Its ease of handling and customization options enable it to fit specialized applications, much appreciated by those who seek tailored solutions in their respective fields. Experience shows that maintenance and longevity of 500 micron nylon mesh are crucial considerations. Users report that its inherent properties, such as resistance to environmental wear and tear, translate to longevity even in harsh conditions. With proper care, including periodic cleaning to remove accumulated particulates, the mesh can serve effectively for extended periods without compromising its integrity. Recent advances in nylon manufacturing technology have further augmented the capabilities of 500 micron mesh. Enhanced weaving techniques have improved its tensile strength, ensuring that it remains invulnerable to stretching or tearing under pressure, thereby increasing user confidence. Moreover, the availability of customizable sizes and shapes means that specific task requirements can be met with precision, supporting innovation and creativity in engineering and design endeavors. In conclusion, the 500 micron nylon mesh continues to maintain its authoritative stance across multiple sectors, providing solutions that marry efficacy with cost-efficiency. Its role is ever-expanding, driven by continuous innovation and user feedback. Thanks to its unparalleled strength, versatility, and credible track record, it remains a trusted component for professionals and enthusiasts striving for excellence in their fields. Whether employed in heavy-duty industrial applications or fine dining establishments, its contribution to operational optimization is both recognized and celebrated.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024