2 月 . 10, 2025 10:20

Back to list

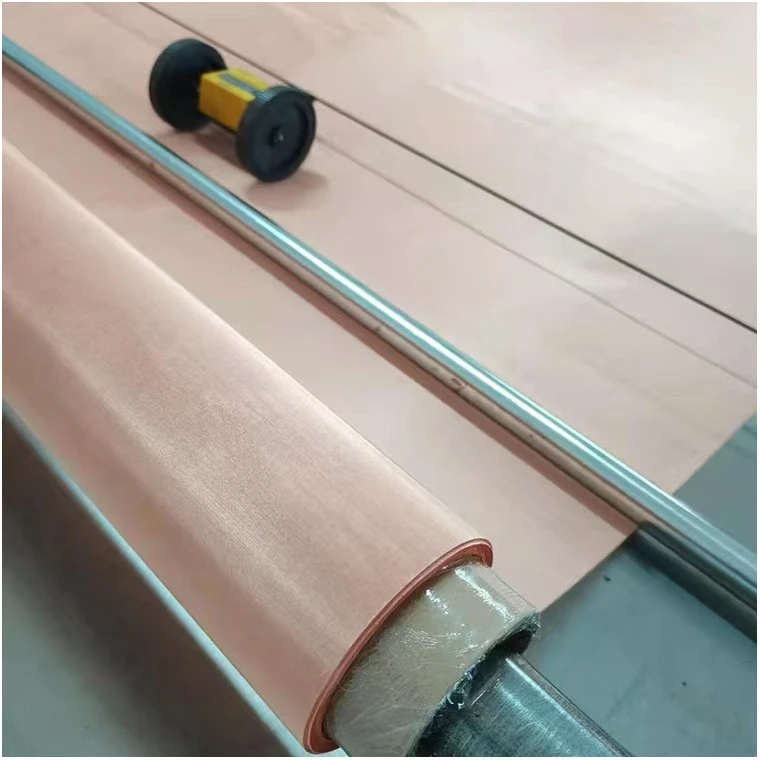

Thickened Nylon Mesh

In industries where precision filtration is paramount, the 10 micron nylon filter cloth stands out as a powerhouse product, lending its unique properties to a variety of applications. Its relevance spans numerous sectors, from pharmaceuticals to food and beverage production, underscoring the profound expertise embedded in its design and implementation.

For those with real-world experience in implementing filtration systems, the operational benefits are clear. The 10 micron nylon filter cloth excels in maintaining operational efficiency across processes, contributing to a consistent final product quality. This is particularly critical in industries like pharmaceuticals, where any deviation can impact efficacy and safety. Users report reduced operational issues and downtime, attributing these improvements to the filter’s adept handling of high-pressure environments and challenging biological particulates. Trust, within this context, is built not just upon product certification, but also through direct user experiences and case studies that illustrate tangible outcomes. Testimonials from seasoned professionals highlight scenarios where switching to a 10 micron nylon filter cloth resulted in measurable increases in productivity and cost savings. Such narratives play a vital role in convincing stakeholders of the product’s value, as they provide concrete evidence of its benefits over alternatives. In summary, the 10 micron nylon filter cloth is a testament to engineering excellence, demonstrating unmatched expertise and reliability in critical filtration applications. Its durability, ease of maintenance, and effectiveness are well-documented amongst professionals, reinforcing its status as a quintessential component in numerous industrial sectors. By prioritizing quality and performance, it establishes itself not only as a product of authority but as a quintessential solution trusted by experts worldwide.

For those with real-world experience in implementing filtration systems, the operational benefits are clear. The 10 micron nylon filter cloth excels in maintaining operational efficiency across processes, contributing to a consistent final product quality. This is particularly critical in industries like pharmaceuticals, where any deviation can impact efficacy and safety. Users report reduced operational issues and downtime, attributing these improvements to the filter’s adept handling of high-pressure environments and challenging biological particulates. Trust, within this context, is built not just upon product certification, but also through direct user experiences and case studies that illustrate tangible outcomes. Testimonials from seasoned professionals highlight scenarios where switching to a 10 micron nylon filter cloth resulted in measurable increases in productivity and cost savings. Such narratives play a vital role in convincing stakeholders of the product’s value, as they provide concrete evidence of its benefits over alternatives. In summary, the 10 micron nylon filter cloth is a testament to engineering excellence, demonstrating unmatched expertise and reliability in critical filtration applications. Its durability, ease of maintenance, and effectiveness are well-documented amongst professionals, reinforcing its status as a quintessential component in numerous industrial sectors. By prioritizing quality and performance, it establishes itself not only as a product of authority but as a quintessential solution trusted by experts worldwide.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024