2 月 . 18, 2025 09:40

Back to list

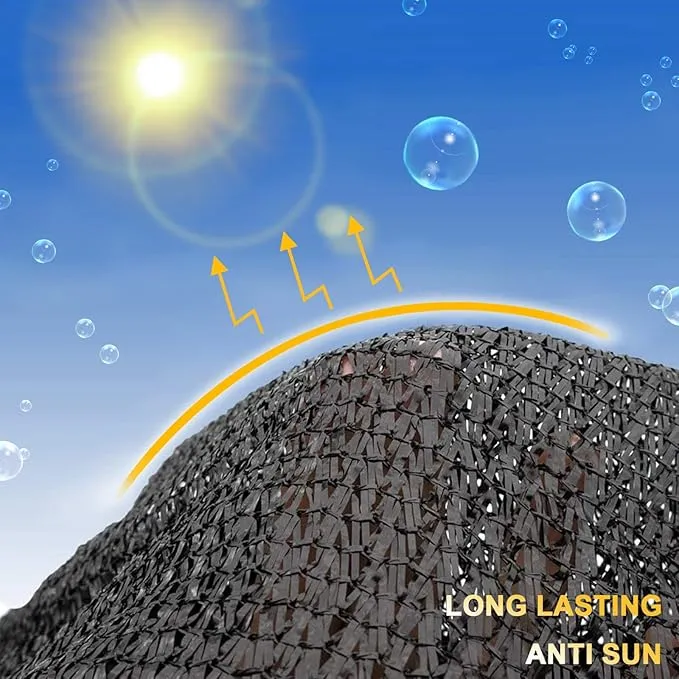

100% HDPE Agricultural Bird Proof Netting Knotted Heavy-Duty Bird Netting

The woven stainless steel mesh, a staple in various industrial and architectural applications, represents an artful blend of form and function. Its genesis is steeped in expertise, reflecting a melding of traditional weaving techniques with modern engineering principles. As a material, it stands out for its durability, versatility, and aesthetic appeal, making it a top choice for architects, builders, and engineers.

Authoritativeness in the woven stainless steel mesh industry is backed by international adherence to quality standards, such as ISO 9001 for quality management and the ASTM standards for material specifications. Manufacturers who have achieved these certifications demonstrate their commitment to producing reliable and high-quality mesh products. Companies with a long-standing history in metal weaving bring an unparalleled level of authority, as they utilize decades of accumulated knowledge to innovate and improve their products continuously. Trustworthiness is critical when selecting a supplier for woven stainless steel mesh. Reputable manufacturers provide detailed product specifications, offer customizable solutions, and ensure transparency in their production and business practices. Customer testimonials and case studies often highlight the reliability of the mesh in challenging environments, providing potential clients with confidence in their purchasing decisions. Furthermore, ongoing research and development within the industry aim to enhance the properties of stainless steel mesh, such as increasing its resistance to more extreme environmental conditions, thereby expanding its usability and life span. In essence, woven stainless steel mesh is more than a mere building material; it embodies a confluence of experience, expertise, authority, and trust. Its proven performance across various applications underscores its superiority in the global market. As industries continue to strive for efficiency coupled with aesthetic quality, woven stainless steel mesh stands ready to meet these demands, supported by the robust knowledge and trustworthy practices of its producers. The ongoing evolution of this material promises new architectural and industrial frontiers, as it adapts to the ever-changing demands of modern engineering and design.

Authoritativeness in the woven stainless steel mesh industry is backed by international adherence to quality standards, such as ISO 9001 for quality management and the ASTM standards for material specifications. Manufacturers who have achieved these certifications demonstrate their commitment to producing reliable and high-quality mesh products. Companies with a long-standing history in metal weaving bring an unparalleled level of authority, as they utilize decades of accumulated knowledge to innovate and improve their products continuously. Trustworthiness is critical when selecting a supplier for woven stainless steel mesh. Reputable manufacturers provide detailed product specifications, offer customizable solutions, and ensure transparency in their production and business practices. Customer testimonials and case studies often highlight the reliability of the mesh in challenging environments, providing potential clients with confidence in their purchasing decisions. Furthermore, ongoing research and development within the industry aim to enhance the properties of stainless steel mesh, such as increasing its resistance to more extreme environmental conditions, thereby expanding its usability and life span. In essence, woven stainless steel mesh is more than a mere building material; it embodies a confluence of experience, expertise, authority, and trust. Its proven performance across various applications underscores its superiority in the global market. As industries continue to strive for efficiency coupled with aesthetic quality, woven stainless steel mesh stands ready to meet these demands, supported by the robust knowledge and trustworthy practices of its producers. The ongoing evolution of this material promises new architectural and industrial frontiers, as it adapts to the ever-changing demands of modern engineering and design.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024