1 月 . 23, 2025 04:16

Back to list

100% HDPE Agricultural Bird Proof Netting Knotted Heavy-Duty Bird Netting

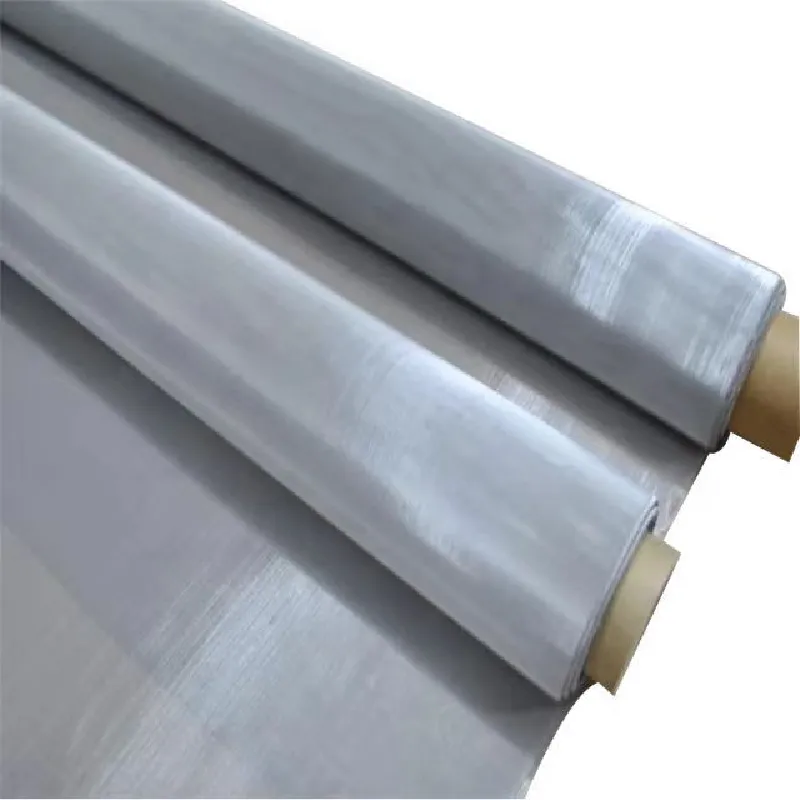

Woven stainless steel mesh has emerged as a cornerstone in varied industries due to its unparalleled blend of flexibility, durability, and corrosion resistance. Understanding its nuanced characteristics can propel your choice towards informed decisions, thereby optimizing its utilization across applications.

From a practical experience viewpoint, users consistently report low maintenance needs, despite harsh operational settings. The longevity of woven stainless steel mesh stems from its non-reactive nature, reducing replacement frequency and operational costs over time. This longevity ensures that industries ranging from food processing to petrochemical refining can rely on it without frequent interruptions for repairs or renovations. The trustworthiness of woven stainless steel mesh is further cemented through rigorous testing and quality assurance protocols. Manufacturers often subject the mesh to tensile strength tests, ensuring it can handle anticipated loads while retaining flexibility. This level of scrutiny in testing builds confidence in its application, particularly in safety-critical roles such as protective screens in hazardous environments. When discussing expertise, it is crucial to note the customizability of woven stainless steel mesh. Its adaptability allows for bespoke solutions tailored to specific project requirements. Whether adjusting mesh aperture for unique filtration needs or altering alloy mixtures to better suit environmental conditions, the mesh’s versatility is a direct reflection of the accumulated knowledge in its production. To conclude, woven stainless steel mesh serves as an exemplary model of reliability, marked by its unmatched combination of strength, adaptability, and resistance to challenging environments. With authentic experiences validating its superiority and comprehensive expertise informing its customization, it stands not just as a robust choice but as an integral component trusted across multiple domains. As industries evolve, the trustworthiness and proven performance of woven stainless steel mesh will continue to underscore its pivotal role, ensuring it remains a material of choice for future innovations.

From a practical experience viewpoint, users consistently report low maintenance needs, despite harsh operational settings. The longevity of woven stainless steel mesh stems from its non-reactive nature, reducing replacement frequency and operational costs over time. This longevity ensures that industries ranging from food processing to petrochemical refining can rely on it without frequent interruptions for repairs or renovations. The trustworthiness of woven stainless steel mesh is further cemented through rigorous testing and quality assurance protocols. Manufacturers often subject the mesh to tensile strength tests, ensuring it can handle anticipated loads while retaining flexibility. This level of scrutiny in testing builds confidence in its application, particularly in safety-critical roles such as protective screens in hazardous environments. When discussing expertise, it is crucial to note the customizability of woven stainless steel mesh. Its adaptability allows for bespoke solutions tailored to specific project requirements. Whether adjusting mesh aperture for unique filtration needs or altering alloy mixtures to better suit environmental conditions, the mesh’s versatility is a direct reflection of the accumulated knowledge in its production. To conclude, woven stainless steel mesh serves as an exemplary model of reliability, marked by its unmatched combination of strength, adaptability, and resistance to challenging environments. With authentic experiences validating its superiority and comprehensive expertise informing its customization, it stands not just as a robust choice but as an integral component trusted across multiple domains. As industries evolve, the trustworthiness and proven performance of woven stainless steel mesh will continue to underscore its pivotal role, ensuring it remains a material of choice for future innovations.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

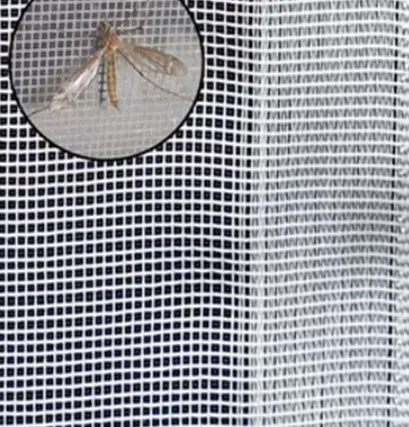

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024