2 月 . 04, 2025 02:51

Back to list

plastic wire mesh

Welded steel wire fabric, often overshadowed by its more famous counterpart—the rebar—is a cornerstone in modern construction, offering durability, versatility, and affordability in a single package. Whether used for roadways, buildings, or infrastructure, this steel reinforcement product deserves a closer look, especially for those seeking innovative solutions in construction.

Moreover, this product aligns with sustainability, a beacon term in modern construction. Steel's inherently recyclable nature positions welded steel wire fabric as a strong contender in green building projects. Its use not only reduces waste, due to its precision-engineered fabrication, but also supports eco-friendly initiatives. Many industry leaders acknowledge these environmental benefits, reinforcing the fabric’s role in sustainable development and enhancing trust in its use. While expertise in selecting appropriate materials is crucial, it is equally important to understand the versatility of welded steel wire fabric. It seamlessly integrates into various types of work, from small-scale residential projects to large-scale industrial applications. Once laid, the fabric accommodates modifications, such as cutting and bending, without compromising its structural capabilities. This adaptability allows for creative solutions in custom designs, often demanded by architects and builders keen on pushing boundaries. The trustworthiness of welded steel wire fabric is further bolstered by rigorous testing standards. Conformance to mechanical property specifications, as per ASTM requirements, guarantees that each batch is suitable for structural applications. By relying on standardized measures, construction professionals can confidently integrate this reinforcement option into their projects, knowing they adhere to internationally recognized safety and quality benchmarks. For any stakeholder, be it an investor, contractor, or architect, the choice of materials rooted in experience, expertise, authoritativeness, and trustworthiness directly influences project outcomes. Welded steel wire fabric embodies these qualities, making it an advantageous consideration for construction professionals aiming not only for durability and strength but also for efficiency, sustainability, and precision in their work.

Moreover, this product aligns with sustainability, a beacon term in modern construction. Steel's inherently recyclable nature positions welded steel wire fabric as a strong contender in green building projects. Its use not only reduces waste, due to its precision-engineered fabrication, but also supports eco-friendly initiatives. Many industry leaders acknowledge these environmental benefits, reinforcing the fabric’s role in sustainable development and enhancing trust in its use. While expertise in selecting appropriate materials is crucial, it is equally important to understand the versatility of welded steel wire fabric. It seamlessly integrates into various types of work, from small-scale residential projects to large-scale industrial applications. Once laid, the fabric accommodates modifications, such as cutting and bending, without compromising its structural capabilities. This adaptability allows for creative solutions in custom designs, often demanded by architects and builders keen on pushing boundaries. The trustworthiness of welded steel wire fabric is further bolstered by rigorous testing standards. Conformance to mechanical property specifications, as per ASTM requirements, guarantees that each batch is suitable for structural applications. By relying on standardized measures, construction professionals can confidently integrate this reinforcement option into their projects, knowing they adhere to internationally recognized safety and quality benchmarks. For any stakeholder, be it an investor, contractor, or architect, the choice of materials rooted in experience, expertise, authoritativeness, and trustworthiness directly influences project outcomes. Welded steel wire fabric embodies these qualities, making it an advantageous consideration for construction professionals aiming not only for durability and strength but also for efficiency, sustainability, and precision in their work.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

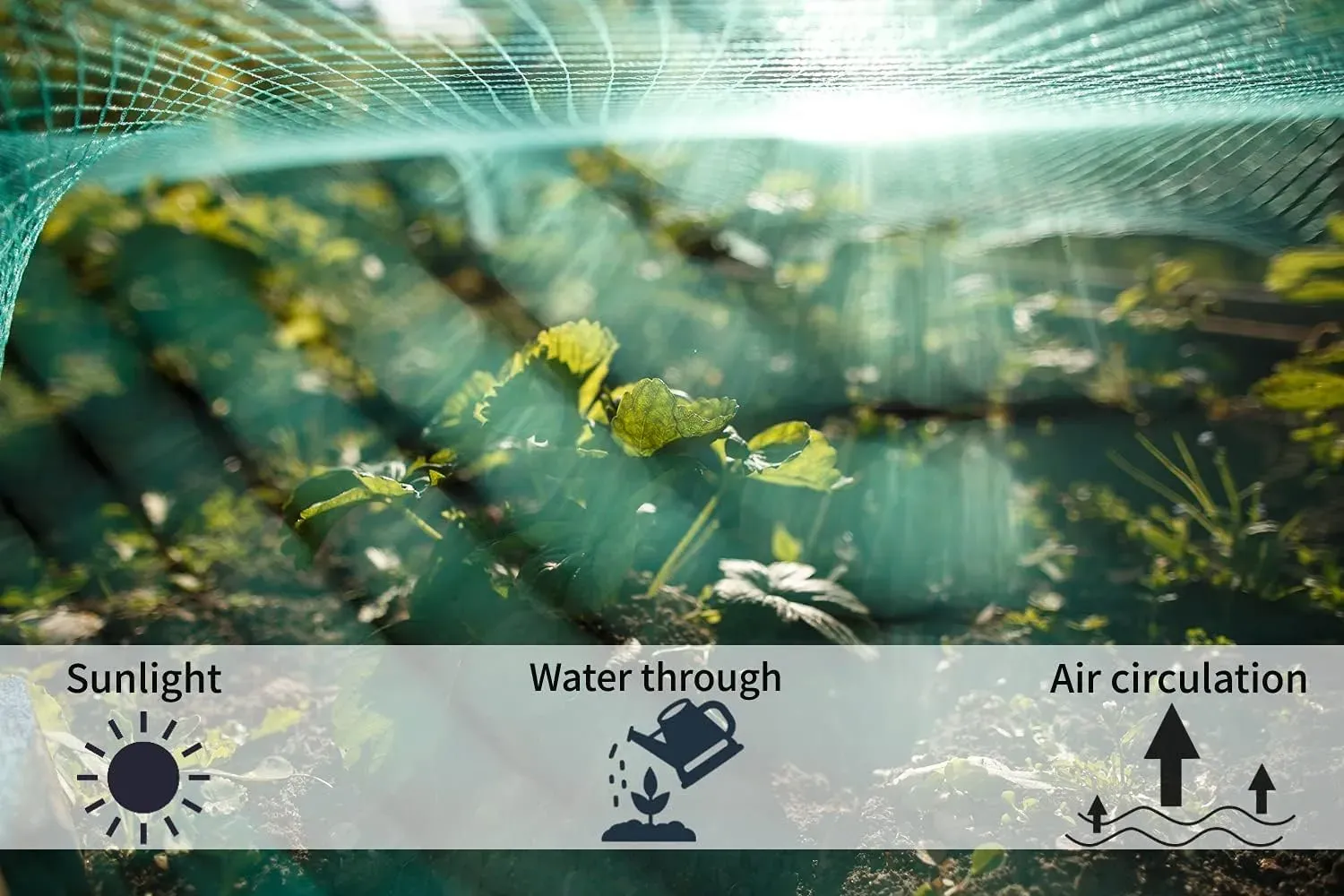

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024