2 月 . 19, 2025 03:12

Back to list

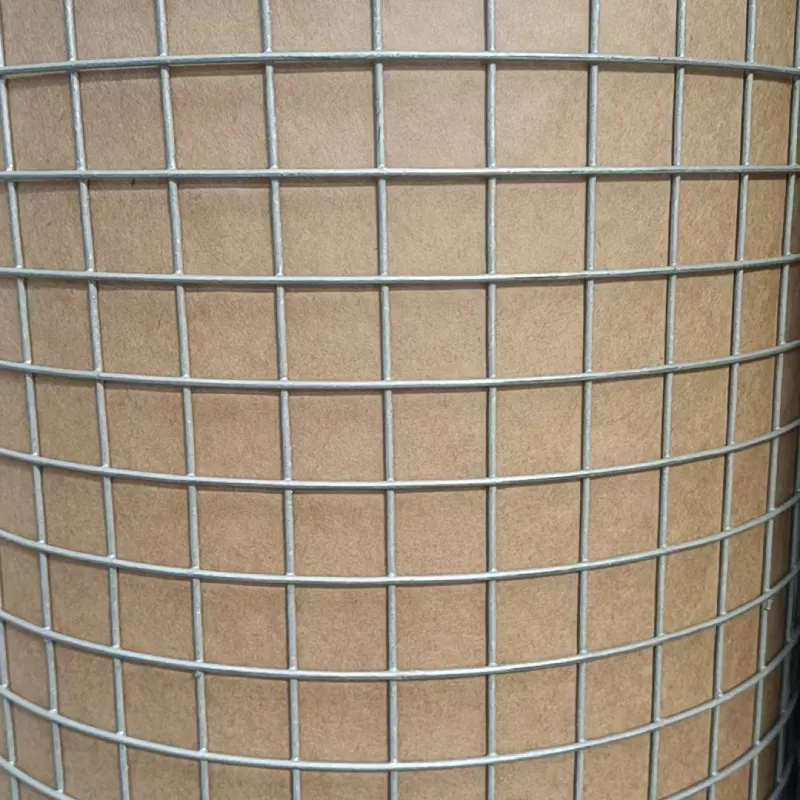

welded steel mesh

Welded steel mesh, an engineering marvel, serves as a critical component in diverse applications ranging from construction to industrial uses. Its significance extends beyond mere material choice, offering structural integrity, durability, and cost-effectiveness. But what exactly makes welded steel mesh stand out, and what should industry professionals know to leverage its full potential? Here's a comprehensive guide through the lens of real-world experience, professional expertise, and authoritative insights.

Trustworthiness in welded steel mesh arises from its history of use and the continuous innovations that enhance its properties. Manufacturers have advanced techniques over years, optimizing weld strength through technological innovations and quality controls. For professionals evaluating supplier options, it’s important to consider certifications and adherence to international standards such as ISO and ASTM, which signify product integrity. The environmental impact of using welded steel mesh is also a key consideration. As sustainability becomes central to engineering discussions, welded steel mesh offers eco-friendly benefits. Steel is inherently recyclable, and its longevity in structural applications means fewer resources are spent on replacements and repairs. Forward-thinking projects often incorporate recycled steel mesh, harmonizing structural needs with environmental stewardship. Finally, real-world implementations of welded steel mesh underline its multifaceted utility. In earthquake-prone zones, its role in reinforcing concrete offers peace of mind with enhanced structural ductility and energy absorption. In the harsh conditions of offshore platforms, galvanized mesh withstands saline corrosion, ensuring operational safety and longevity. In conclusion, welded steel mesh represents a synthesis of practical expertise, professional trust, and authoritative validation. Its applications and advantages are vast, guided by a history of innovation and an ever-evolving understanding of structural demands. For professionals, making informed decisions about utilizing welded steel mesh means considering its proven performance, adaptability, compliance with standards, and environmental impact. Understanding these facets equips industry stakeholders with the knowledge to employ welded steel mesh effectively in a wide array of projects, ensuring both safety and sustainability.

Trustworthiness in welded steel mesh arises from its history of use and the continuous innovations that enhance its properties. Manufacturers have advanced techniques over years, optimizing weld strength through technological innovations and quality controls. For professionals evaluating supplier options, it’s important to consider certifications and adherence to international standards such as ISO and ASTM, which signify product integrity. The environmental impact of using welded steel mesh is also a key consideration. As sustainability becomes central to engineering discussions, welded steel mesh offers eco-friendly benefits. Steel is inherently recyclable, and its longevity in structural applications means fewer resources are spent on replacements and repairs. Forward-thinking projects often incorporate recycled steel mesh, harmonizing structural needs with environmental stewardship. Finally, real-world implementations of welded steel mesh underline its multifaceted utility. In earthquake-prone zones, its role in reinforcing concrete offers peace of mind with enhanced structural ductility and energy absorption. In the harsh conditions of offshore platforms, galvanized mesh withstands saline corrosion, ensuring operational safety and longevity. In conclusion, welded steel mesh represents a synthesis of practical expertise, professional trust, and authoritative validation. Its applications and advantages are vast, guided by a history of innovation and an ever-evolving understanding of structural demands. For professionals, making informed decisions about utilizing welded steel mesh means considering its proven performance, adaptability, compliance with standards, and environmental impact. Understanding these facets equips industry stakeholders with the knowledge to employ welded steel mesh effectively in a wide array of projects, ensuring both safety and sustainability.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024