Top Manufacturers of Stainless Steel Mesh for Various Applications

An Overview of Stainless Steel Mesh Manufacturers

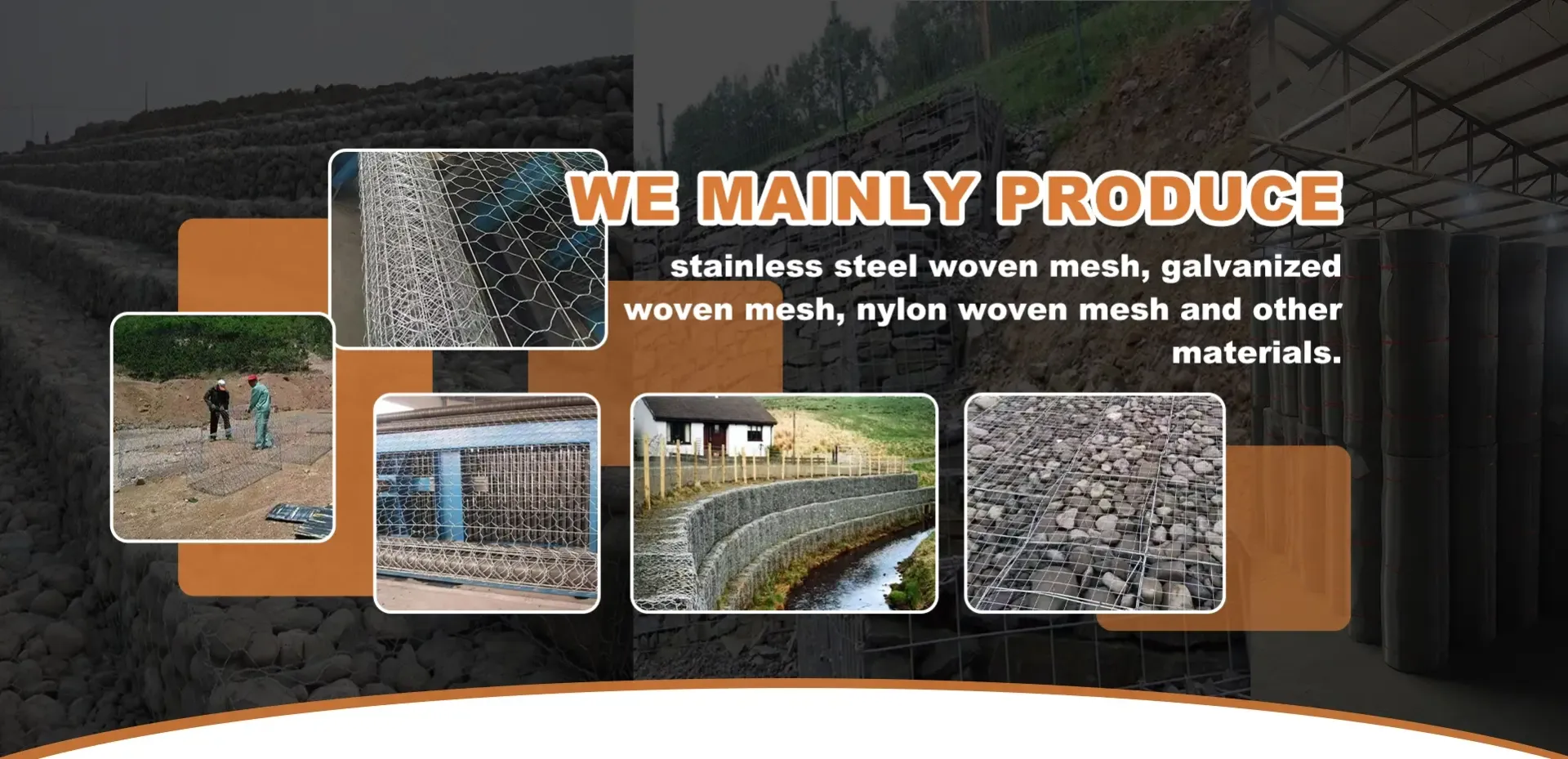

Stainless steel mesh is a versatile and durable material used across various industries, including construction, food processing, pharmaceuticals, and more. Its resistance to corrosion, strength, and aesthetic appeal make it an ideal choice for a myriad of applications. As the demand for stainless steel mesh continues to grow, so does the number of manufacturers in this sector. This article aims to provide an overview of stainless steel mesh manufacturers, their products, and the factors to consider when selecting one.

Understanding Stainless Steel Mesh

Stainless steel mesh consists of woven metal wires made primarily from stainless steel, which is an alloy that contains chromium, nickel, and other elements to enhance its properties. This type of mesh is available in different grades, with the most common being 304 and 316. Grade 304 is often used for general applications, whereas grade 316 is preferred for environments that require higher resistance to corrosion, such as marine applications.

Key Applications of Stainless Steel Mesh

Manufacturers produce stainless steel mesh for many uses, including

1. Filtration Used for filtering fluids and gases in industries such as chemical processing, food and beverage, and water treatment. 2. Safety and Security Implemented in safety barriers, fencing, and window guards to provide security while maintaining visibility.

3. Architectural Elements Used in the construction of decorative screens, railings, and facades, enhancing both aesthetics and functionality.

4. Industrial Applications Supports various processes in manufacturing and can be found in equipment such as sieves, conveyors, and vibrating screens.

Choosing the Right Manufacturer

stainless steel mesh manufacturers

When selecting a stainless steel mesh manufacturer, several factors should be considered

1. Quality and Standards Ensure that the manufacturer adheres to industry standards, such as ISO certifications, ensuring product quality and reliability.

2. Product Range A good manufacturer should offer a wide variety of mesh types, including different wire diameters, mesh patterns, and sizes, catering to diverse industry needs.

3. Customization Options Many applications require specific mesh characteristics. A capable manufacturer should provide customization in terms of woven patterns, coatings, and finishes to meet particular requirements.

4. Expertise and Experience Look for manufacturers with substantial experience and a strong track record. Their expertise can offer valuable insights and aid in selecting the most suitable mesh for specific applications.

5. Customer Service Good communication and customer service are essential. A trustworthy manufacturer should provide support throughout the purchasing process, from selection to post-purchase assistance.

6. Pricing and Delivery Compare pricing among different manufacturers but remember that the cheapest option is not always the best. Consider the balance between cost and quality. Additionally, check their delivery timelines to ensure they meet your project deadlines.

Conclusion

The stainless steel mesh industry has numerous manufacturers that cater to various sectors, from industrial to architectural applications. Understanding the capabilities and offerings of these manufacturers allows businesses to select the right partner for their needs. By considering factors such as quality, product range, customization options, and customer service, organizations can find a reliable supplier that meets their specifications. The continued innovation within this industry promises to enhance the functionality and scope of stainless steel mesh, making it an increasingly essential material across several fields.

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024