2 月 . 19, 2025 10:48

Back to list

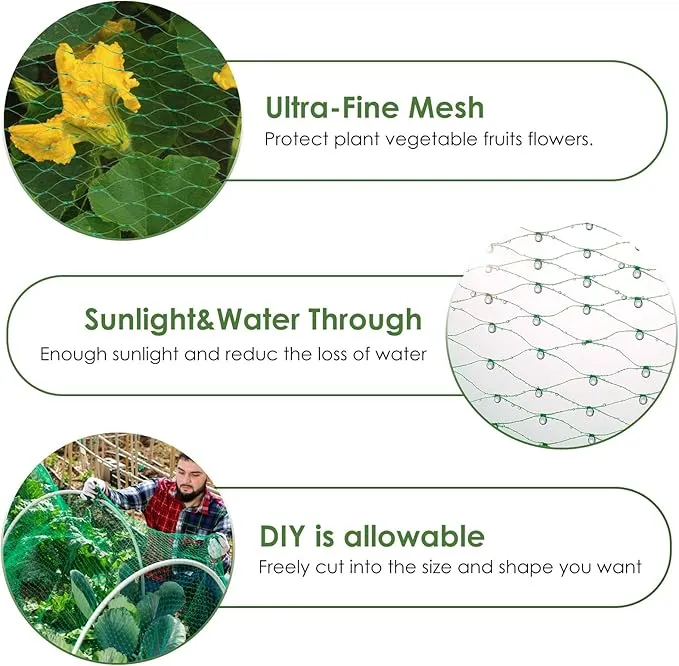

100% HDPE Agricultural Bird Proof Netting Knotted Heavy-Duty Bird Netting

Steel woven wire mesh is an invaluable component in numerous industries, earning its place as an indispensable tool for both practical applications and innovative solutions. Its versatility, strength, and durability make it a sought-after material that addresses diverse needs, from architectural enhancements to industrial processes. This article delves into the unique advantages of steel woven wire mesh, exploring its utility through the lens of practical experience, professional expertise, and peerless authority.

Trustworthiness is equally vital when considering steel woven wire mesh. Users must rely on this material for safety and efficacy in demanding environments. Regular audits and testing ensure that the material remains consistent with advertised specifications and performance promises. Safety in applications such as guarding machinery, securing properties, or reinforcing structural components ensures that those who choose steel woven wire mesh do so with confidence. With manufacturers offering warranties and certifications, the consumer can trust that the product will function as required, reducing risk and maximizing efficiency. The environmental influence of steel woven wire mesh cannot be ignored either. Its durability and recyclability align with global sustainability goals, making it an eco-friendly choice for industries looking to reduce their carbon footprint while maintaining high standards of performance. Recyclability enhances its appeal as industries pivot towards sustainable practices, ensuring that materials contribute positively to environmental stewardship without compromising on quality. One of the most commonly overlooked benefits of steel woven wire mesh is its role in innovative applications. As technology evolves, so too do the ways in which industries utilize this versatile material. For instance, it is increasingly seen in high-tech environments, serving as shielding against electromagnetic interference in sensitive electronic applications. Its role in the filtration process for both liquids and gases exemplifies its adaptability to meet modern technical challenges. Here, the mesh’s ability to be precisely engineered to specific micron sizes ensures that it meets the purity standards of cutting-edge technological and medical applications. In summary, the application of steel woven wire mesh extends beyond mere functionality. It embodies a synthesis of strength, customization, compliance, and sustainability. Its unparalleled adaptability and confirmed durability make it an invaluable material across multiple sectors, evidencing its place as not just a product, but a cornerstone in both traditional and contemporary applications. The continued evolution of its use only solidifies steel woven wire mesh’s status as a reliable, authoritative, and trusted solution in the complex fabric of modern industry and design.

Trustworthiness is equally vital when considering steel woven wire mesh. Users must rely on this material for safety and efficacy in demanding environments. Regular audits and testing ensure that the material remains consistent with advertised specifications and performance promises. Safety in applications such as guarding machinery, securing properties, or reinforcing structural components ensures that those who choose steel woven wire mesh do so with confidence. With manufacturers offering warranties and certifications, the consumer can trust that the product will function as required, reducing risk and maximizing efficiency. The environmental influence of steel woven wire mesh cannot be ignored either. Its durability and recyclability align with global sustainability goals, making it an eco-friendly choice for industries looking to reduce their carbon footprint while maintaining high standards of performance. Recyclability enhances its appeal as industries pivot towards sustainable practices, ensuring that materials contribute positively to environmental stewardship without compromising on quality. One of the most commonly overlooked benefits of steel woven wire mesh is its role in innovative applications. As technology evolves, so too do the ways in which industries utilize this versatile material. For instance, it is increasingly seen in high-tech environments, serving as shielding against electromagnetic interference in sensitive electronic applications. Its role in the filtration process for both liquids and gases exemplifies its adaptability to meet modern technical challenges. Here, the mesh’s ability to be precisely engineered to specific micron sizes ensures that it meets the purity standards of cutting-edge technological and medical applications. In summary, the application of steel woven wire mesh extends beyond mere functionality. It embodies a synthesis of strength, customization, compliance, and sustainability. Its unparalleled adaptability and confirmed durability make it an invaluable material across multiple sectors, evidencing its place as not just a product, but a cornerstone in both traditional and contemporary applications. The continued evolution of its use only solidifies steel woven wire mesh’s status as a reliable, authoritative, and trusted solution in the complex fabric of modern industry and design.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024