2 月 . 04, 2025 00:58

Back to list

steel wire fabric

Steel wire fabric, commonly known in the construction industry as welded wire mesh, is a key ingredient in modern building practices. This versatile material combines durability with flexibility, making it an essential choice for architects and builders alike. As someone deeply entrenched in the field of construction and materials engineering, I can attest to its pivotal role not just in infrastructure, but in shaping our cities' skylines.

Trustworthiness is further enhanced by the transparency offered through manufacturers' certifications and material testing results. Consumers and professionals alike can rely on the documented performance metrics, which are critical when working on projects that require strict adherence to safety and quality standards. These certifications guarantee that the steel wire fabric has passed all necessary inspections and meets prevailing construction codes, hence ensuring the safety of the structure and its occupants. Moreover, the environmental impact is a growing consideration; steel wire fabric makes strides in this area as well. Its durability means fewer resources are spent on repairs or replacements, aligning with sustainability initiatives within the industry. Furthermore, the recyclability of steel positions it as an eco-friendly option, promoting green building practices that minimize waste and conserve resources. In the realm of innovative construction technology, steel wire fabric continues to evolve. Enhanced production techniques and the incorporation of advanced materials like high-strength steel push the boundaries of what is possible. This evolution provides an exciting frontier for experts seeking to implement cutting-edge solutions in their projects. Ultimately, steel wire fabric stands as a testament to the advances in engineering and material sciences. Its widespread use across a multitude of construction projects globally highlights its unmatched versatility and indispensable role in engineering robust, reliable, and aesthetic concrete structures. For industry professionals and stakeholders, investing in quality steel wire fabric not only guarantees performance but also aligns with sustainable, future-forward construction practices.

Trustworthiness is further enhanced by the transparency offered through manufacturers' certifications and material testing results. Consumers and professionals alike can rely on the documented performance metrics, which are critical when working on projects that require strict adherence to safety and quality standards. These certifications guarantee that the steel wire fabric has passed all necessary inspections and meets prevailing construction codes, hence ensuring the safety of the structure and its occupants. Moreover, the environmental impact is a growing consideration; steel wire fabric makes strides in this area as well. Its durability means fewer resources are spent on repairs or replacements, aligning with sustainability initiatives within the industry. Furthermore, the recyclability of steel positions it as an eco-friendly option, promoting green building practices that minimize waste and conserve resources. In the realm of innovative construction technology, steel wire fabric continues to evolve. Enhanced production techniques and the incorporation of advanced materials like high-strength steel push the boundaries of what is possible. This evolution provides an exciting frontier for experts seeking to implement cutting-edge solutions in their projects. Ultimately, steel wire fabric stands as a testament to the advances in engineering and material sciences. Its widespread use across a multitude of construction projects globally highlights its unmatched versatility and indispensable role in engineering robust, reliable, and aesthetic concrete structures. For industry professionals and stakeholders, investing in quality steel wire fabric not only guarantees performance but also aligns with sustainable, future-forward construction practices.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

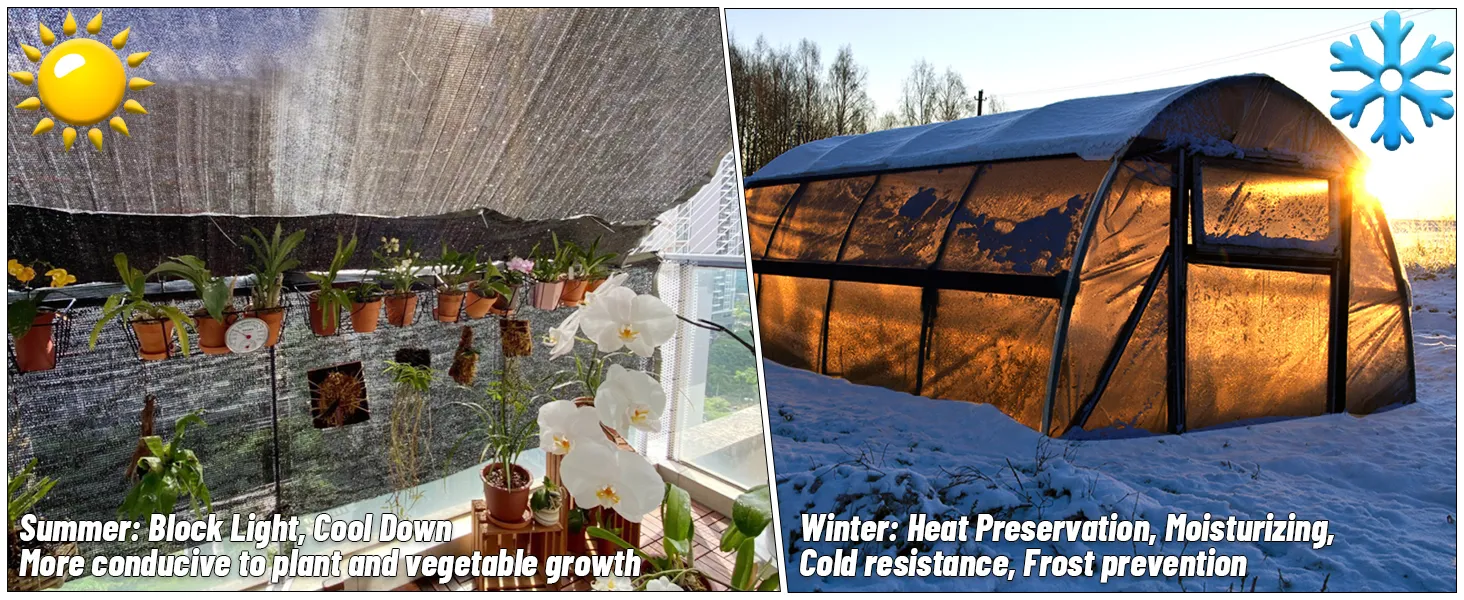

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024