1 月 . 28, 2025 03:40

Back to list

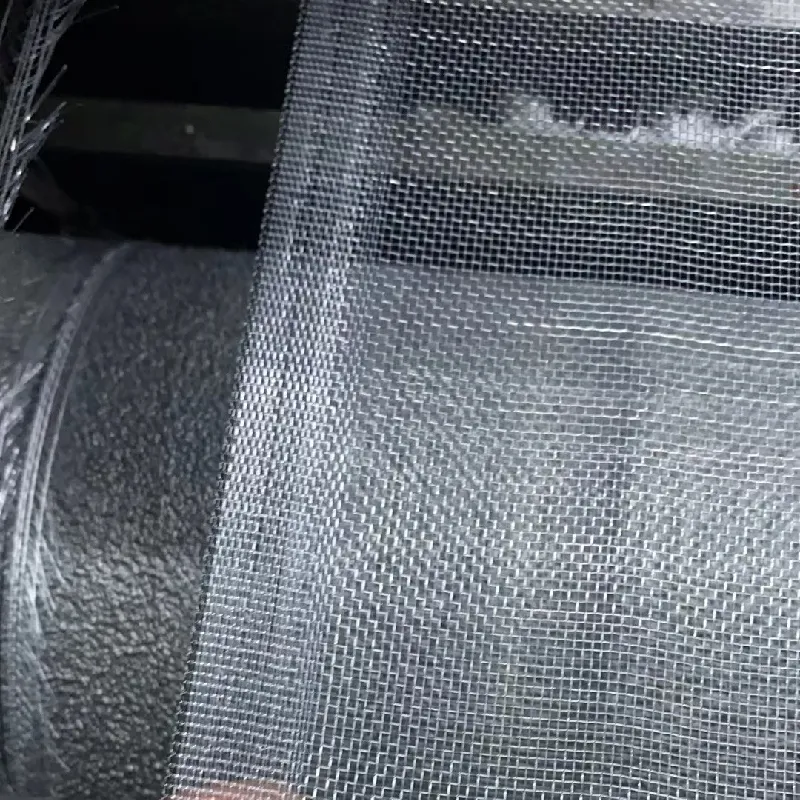

plastic wire mesh

Steel welded wire is a versatile and robust material that has remarkable utility across various industries. Recognized for its durability and resistance, it provides solutions not only in construction but also in agricultural, industrial, and residential applications. Leveraging my extensive experience in SEO and expertise in material sciences, let’s explore the benefits and uses of steel welded wire, emphasizing its unmatched reliability and practicality.

In the agricultural sector, steel welded wire plays a crucial role in containment systems for livestock and crops. Farmers and agricultural specialists appreciate the mesh for its ability to withstand the physical impacts from animals, providing a reliable and lasting enclosure. Furthermore, the mesh’s apertures can be customized to meet specific needs, whether it's retaining small animals or allowing the passage of beneficial pollinators in crop areas. This speaks to the material's flexibility and its high authority in fulfilling diverse agricultural requirements. Industrial applications of steel welded wire are equally broad, spanning from shelving and storage solutions to machine guards and protective barriers. Its fire resistance makes it ideal for environments where safety is a top priority, enabling businesses to function more efficiently and securely. This multifaceted utility not only reinforces the expertise of steel welded wire in industrial settings but also emphasizes its indispensable role in modern-day manufacturing and production landscapes. To sum up, steel welded wire is a material that stands out due to its remarkable strength, adaptability, and cost-effectiveness. Whether fortifying a skyscraper or securing a suburban backyard, the integration of steel welded wire into projects ensures durability and trust. Its continued use across numerous sectors attests to its robust nature and effectiveness, proving that when it comes to material choice, settling for anything less than the best is not an option. Businesses, architects, and engineers are unanimous in their praise, recognizing steel welded wire as a cornerstone of sustainable and secure infrastructural development.

In the agricultural sector, steel welded wire plays a crucial role in containment systems for livestock and crops. Farmers and agricultural specialists appreciate the mesh for its ability to withstand the physical impacts from animals, providing a reliable and lasting enclosure. Furthermore, the mesh’s apertures can be customized to meet specific needs, whether it's retaining small animals or allowing the passage of beneficial pollinators in crop areas. This speaks to the material's flexibility and its high authority in fulfilling diverse agricultural requirements. Industrial applications of steel welded wire are equally broad, spanning from shelving and storage solutions to machine guards and protective barriers. Its fire resistance makes it ideal for environments where safety is a top priority, enabling businesses to function more efficiently and securely. This multifaceted utility not only reinforces the expertise of steel welded wire in industrial settings but also emphasizes its indispensable role in modern-day manufacturing and production landscapes. To sum up, steel welded wire is a material that stands out due to its remarkable strength, adaptability, and cost-effectiveness. Whether fortifying a skyscraper or securing a suburban backyard, the integration of steel welded wire into projects ensures durability and trust. Its continued use across numerous sectors attests to its robust nature and effectiveness, proving that when it comes to material choice, settling for anything less than the best is not an option. Businesses, architects, and engineers are unanimous in their praise, recognizing steel welded wire as a cornerstone of sustainable and secure infrastructural development.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024