1 月 . 23, 2025 00:56

Back to list

steel mesh screen

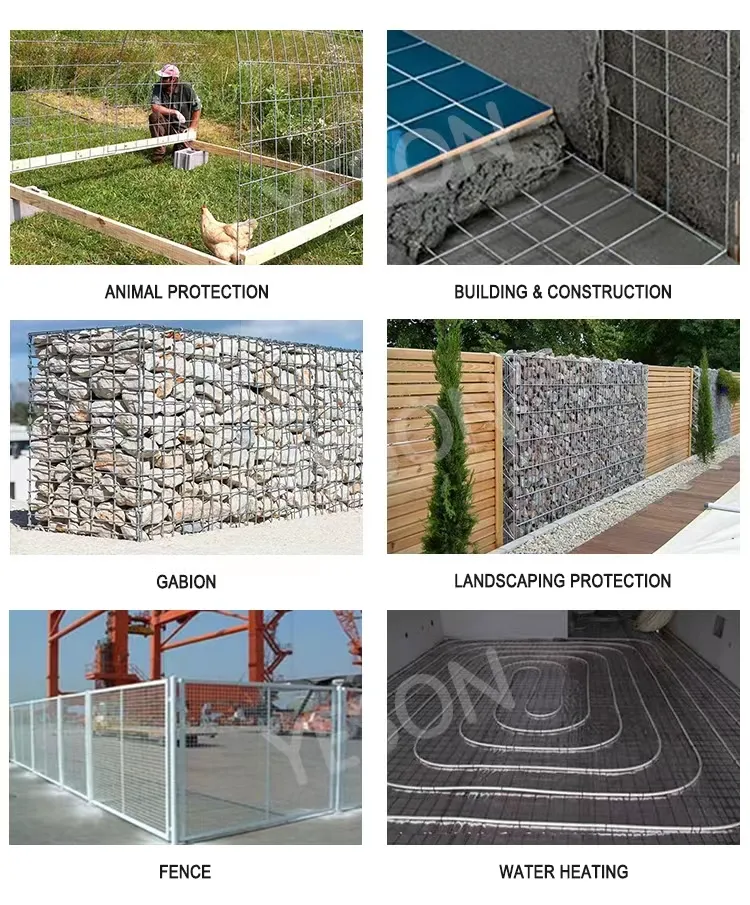

Steel mesh screens have emerged as indispensable components in various industries, offering unparalleled durability and versatile functionality. A savvy choice for those seeking robustness and longevity, these screens are made from intricately woven steel wires, creating a mesh that stands up to rigorous use and environmental stressors.

The trustworthiness of steel mesh screens is borne out by decades of use in critical applications, such as industrial filtration systems, safety cages, and protective installations. Testimonials from seasoned professionals, who have relied on these screens in their projects, cement their reputation for exceptional performance. Clients often return to steel mesh screens, citing their track record for dependability and efficiency. When choosing a steel mesh screen, consider the particular requirements of your project. The mesh's density and wire gauge can affect its strength and permeability, making these factors crucial depending on the application. Consultation with experts who can guide the selection process ensures that the screen meets the specific challenges it will face. Innovations in the production of steel mesh screens have opened new possibilities, expanding their utility even further. Advanced manufacturing techniques have led to the development of screens with enhanced properties, such as increased resistance to chemical exposure or customized mesh patterns for specialized tasks. In summary, the compact blend of experience, expertise, authoritativeness, and trustworthiness makes steel mesh screens an exemplary choice for industries that demand high performance and reliability. From their robust construction to their adaptability across numerous applications, these screens provide solutions that few other materials can match. Their established track record of success across diverse sectors speaks volumes about their role as a crucial component in modern industrial and construction projects, underscoring their status as a product you can depend on.

The trustworthiness of steel mesh screens is borne out by decades of use in critical applications, such as industrial filtration systems, safety cages, and protective installations. Testimonials from seasoned professionals, who have relied on these screens in their projects, cement their reputation for exceptional performance. Clients often return to steel mesh screens, citing their track record for dependability and efficiency. When choosing a steel mesh screen, consider the particular requirements of your project. The mesh's density and wire gauge can affect its strength and permeability, making these factors crucial depending on the application. Consultation with experts who can guide the selection process ensures that the screen meets the specific challenges it will face. Innovations in the production of steel mesh screens have opened new possibilities, expanding their utility even further. Advanced manufacturing techniques have led to the development of screens with enhanced properties, such as increased resistance to chemical exposure or customized mesh patterns for specialized tasks. In summary, the compact blend of experience, expertise, authoritativeness, and trustworthiness makes steel mesh screens an exemplary choice for industries that demand high performance and reliability. From their robust construction to their adaptability across numerous applications, these screens provide solutions that few other materials can match. Their established track record of success across diverse sectors speaks volumes about their role as a crucial component in modern industrial and construction projects, underscoring their status as a product you can depend on.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024