2 月 . 03, 2025 05:23

Back to list

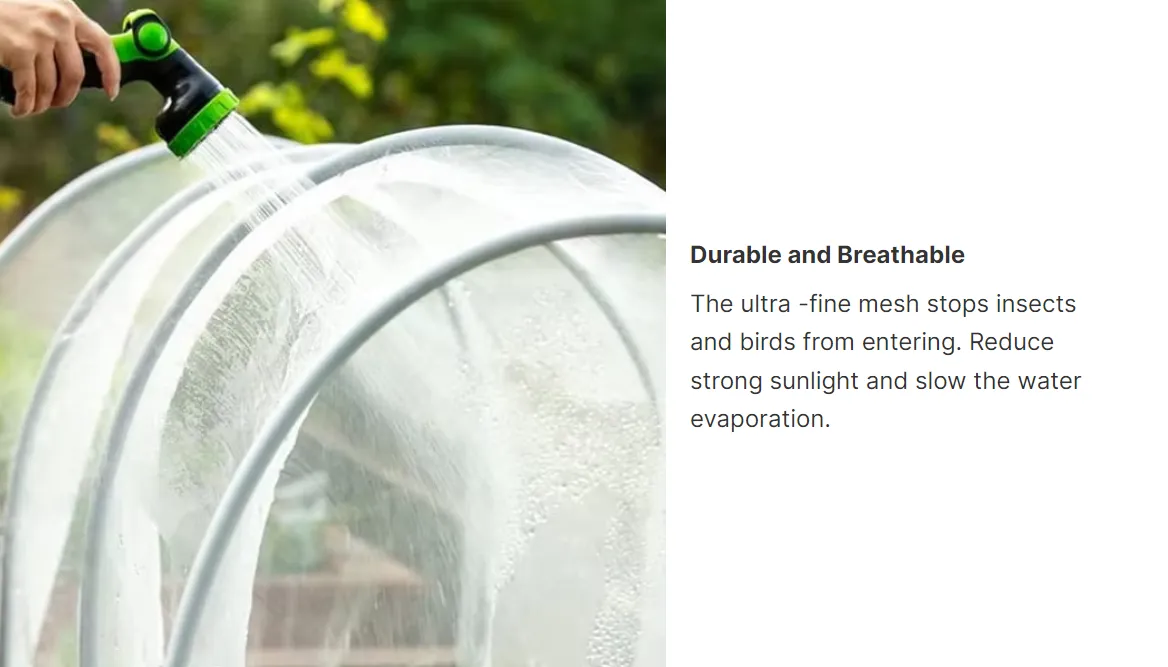

Good Quality Greenhouse Insect Net for Vegetable

Steel mesh, often seen as a vital component in the construction of cages, showcases a blend of durability and versatility unmatched by other materials. Whether it’s for constructing animal enclosures, bird cages, or utilitarian storage solutions, this product has cemented its status as a staple in many industries. Understanding its strengths and applications can guide consumers to make informed choices, ensuring both safety and efficacy in their projects.

The trustworthiness of steel mesh is reflected in its widespread adoption. Industries ranging from agriculture to construction rely heavily on its dependability. Testimonials from experienced users highlight its consistency in performance, noting how it withstands both physical stress and environmental wear for extended periods. The simple yet effective design of steel mesh has earned the trust of engineers and craftsmen worldwide, who regard it as a fundamental resource in their toolkit. Choosing the right steel mesh for a specific cage project involves understanding the intricacies of wire gauge and aperture size. The gauge determines the thickness and, consequently, the strength of the mesh, while the aperture size affects visibility and airflow. For larger animals, a thicker gauge and smaller apertures are advisable to provide greater resistance to force and contain any potential escape attempts. Conversely, smaller creatures, like birds, benefit from finer gauges and larger apertures to ensure adequate ventilation and viewing angles. When purchasing steel mesh, it’s vital to consider the product's compliance with industry standards. Expertly manufactured steel mesh should meet, if not surpass, these benchmarks, guaranteeing both safety and quality. Documentation and certification from reputable manufacturers can bolster confidence in the product’s authenticity and reliability. In summary, steel mesh stands as a testament to the power of innovation in traditional materials. By combining modern manufacturing techniques with its timeless attributes of strength and adaptability, it offers an unparalleled solution for cage construction across numerous fields. Its balance of resilience, flexibility, and safety positions it as a reliable choice for anyone looking to construct durable and long-lasting enclosures. As consumers, selecting the right type of steel mesh can significantly impact the success and durability of a project, aligning with both practical needs and industry best practices.

The trustworthiness of steel mesh is reflected in its widespread adoption. Industries ranging from agriculture to construction rely heavily on its dependability. Testimonials from experienced users highlight its consistency in performance, noting how it withstands both physical stress and environmental wear for extended periods. The simple yet effective design of steel mesh has earned the trust of engineers and craftsmen worldwide, who regard it as a fundamental resource in their toolkit. Choosing the right steel mesh for a specific cage project involves understanding the intricacies of wire gauge and aperture size. The gauge determines the thickness and, consequently, the strength of the mesh, while the aperture size affects visibility and airflow. For larger animals, a thicker gauge and smaller apertures are advisable to provide greater resistance to force and contain any potential escape attempts. Conversely, smaller creatures, like birds, benefit from finer gauges and larger apertures to ensure adequate ventilation and viewing angles. When purchasing steel mesh, it’s vital to consider the product's compliance with industry standards. Expertly manufactured steel mesh should meet, if not surpass, these benchmarks, guaranteeing both safety and quality. Documentation and certification from reputable manufacturers can bolster confidence in the product’s authenticity and reliability. In summary, steel mesh stands as a testament to the power of innovation in traditional materials. By combining modern manufacturing techniques with its timeless attributes of strength and adaptability, it offers an unparalleled solution for cage construction across numerous fields. Its balance of resilience, flexibility, and safety positions it as a reliable choice for anyone looking to construct durable and long-lasting enclosures. As consumers, selecting the right type of steel mesh can significantly impact the success and durability of a project, aligning with both practical needs and industry best practices.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024