2 月 . 03, 2025 04:21

Back to list

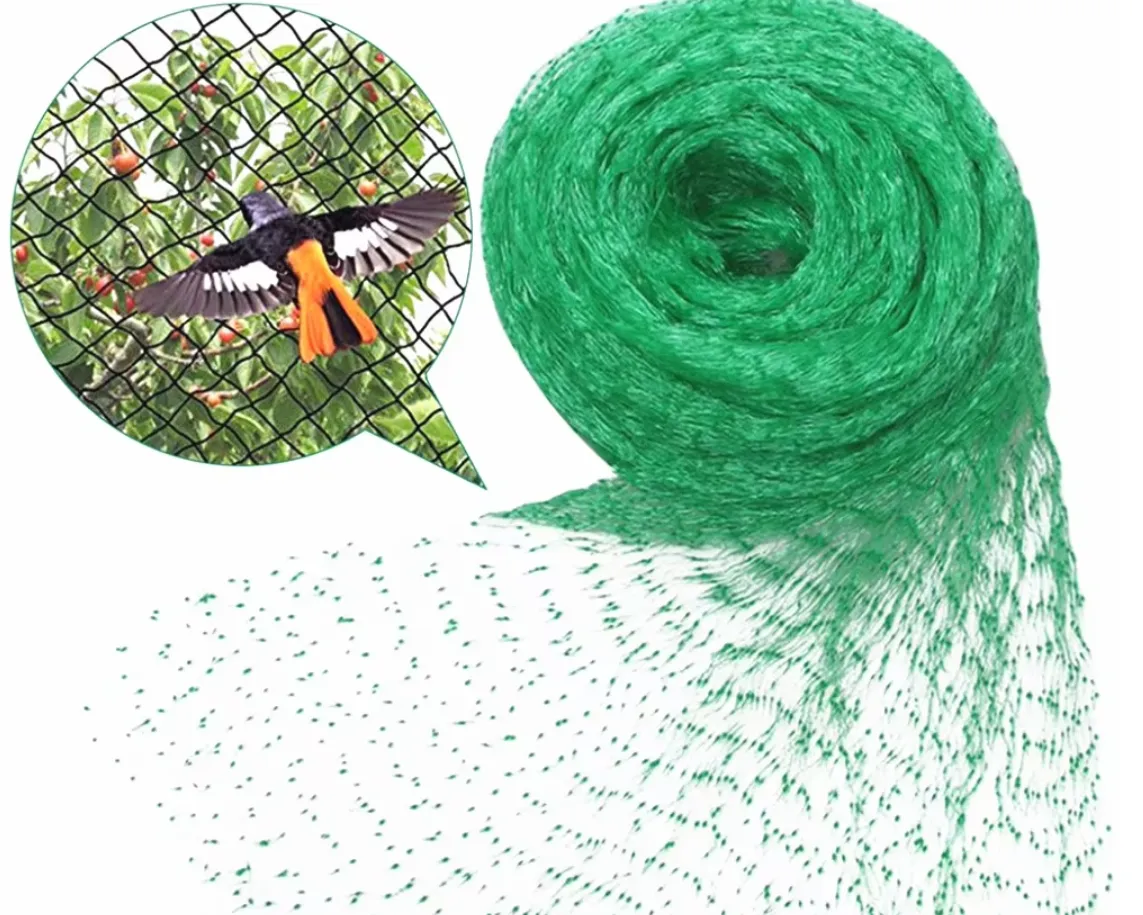

20x20mm Mesh Size Knitted Anti Bird Nets HDPE Agriculture Bird Netting Roll For Birds

Crafting resilient and durable structures hinges on using high-quality materials like steel galvanized mesh. This remarkable product is at the forefront of construction innovation, renowned for balancing strength, flexibility, and corrosion resistance. Understanding its benefits and applications is crucial for construction professionals seeking to optimize the quality and longevity of their projects.

Industry leaders in construction materials often champion the use of steel galvanized mesh for its cost-efficiency over time. While initial costs may be higher compared to non-galvanized options, the reduced maintenance and repair expenses balance the investment. This financial advantage, combined with its long-term durability, makes galvanized mesh a preferred choice for projects with a focus on sustainability and budget management. From an authority standpoint, the choice to use steel galvanized mesh is backed by extensive research and industry standards. Organizations like ASTM International govern the specifications and quality assurance of galvanized products, ensuring compliance with rigorous criteria. Builders and engineers rely on these standards to guide their materials choices, knowing that adherence to such guidelines upholds safety and quality benchmarks. Trustworthiness in recommending steel galvanized mesh also derives from numerous testimonials and case studies highlighting successful applications. Projects worldwide using galvanized mesh often report enhanced durability and performance, reinforcing its reputation as a trustworthy material choice. Client feedback consistently underscores the value of investing in materials that deliver consistent results and robust infrastructure, cementing the role of galvanized mesh as a foundational element of modern construction. For professionals in the field, leveraging the full potential of steel galvanized mesh requires not only familiarity with its technical aspects but also a commitment to embracing cutting-edge construction practices. Continuing education and staying updated with the latest advancements in material science ensure that the utilization of galvanized mesh aligns with evolving industry standards and innovations. The strategic use of high-quality steel galvanized mesh underscores a commitment to excellence in construction. Its proven reliability, backed by science and extensive field experience, makes it an indispensable part of any project where strength, longevity, and environmental resilience are crucial. As construction demands grow and the need for sustainable materials increases, galvanized mesh stands out as a symbol of industry-leading quality and innovation.

Industry leaders in construction materials often champion the use of steel galvanized mesh for its cost-efficiency over time. While initial costs may be higher compared to non-galvanized options, the reduced maintenance and repair expenses balance the investment. This financial advantage, combined with its long-term durability, makes galvanized mesh a preferred choice for projects with a focus on sustainability and budget management. From an authority standpoint, the choice to use steel galvanized mesh is backed by extensive research and industry standards. Organizations like ASTM International govern the specifications and quality assurance of galvanized products, ensuring compliance with rigorous criteria. Builders and engineers rely on these standards to guide their materials choices, knowing that adherence to such guidelines upholds safety and quality benchmarks. Trustworthiness in recommending steel galvanized mesh also derives from numerous testimonials and case studies highlighting successful applications. Projects worldwide using galvanized mesh often report enhanced durability and performance, reinforcing its reputation as a trustworthy material choice. Client feedback consistently underscores the value of investing in materials that deliver consistent results and robust infrastructure, cementing the role of galvanized mesh as a foundational element of modern construction. For professionals in the field, leveraging the full potential of steel galvanized mesh requires not only familiarity with its technical aspects but also a commitment to embracing cutting-edge construction practices. Continuing education and staying updated with the latest advancements in material science ensure that the utilization of galvanized mesh aligns with evolving industry standards and innovations. The strategic use of high-quality steel galvanized mesh underscores a commitment to excellence in construction. Its proven reliability, backed by science and extensive field experience, makes it an indispensable part of any project where strength, longevity, and environmental resilience are crucial. As construction demands grow and the need for sustainable materials increases, galvanized mesh stands out as a symbol of industry-leading quality and innovation.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024