1 月 . 26, 2025 02:18

Back to list

Nylon Filter Mesh

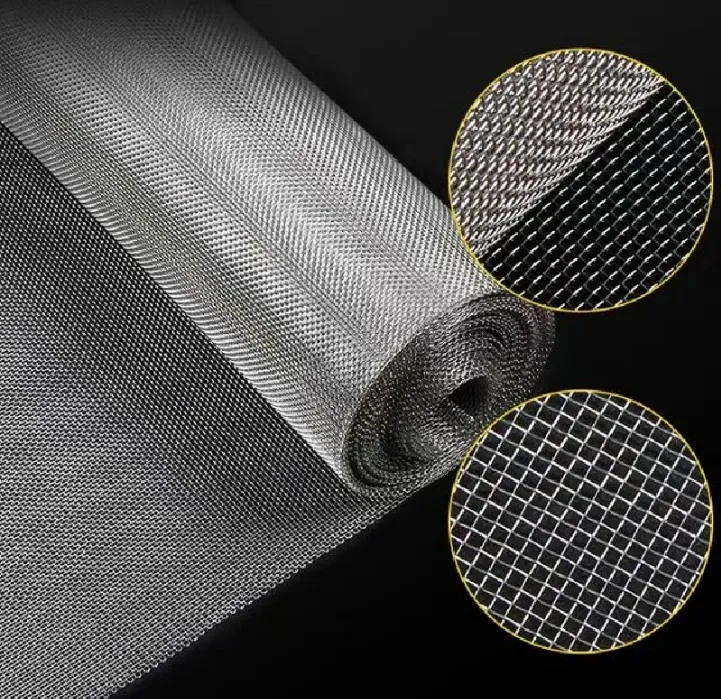

In the world of industrial and commercial filtration, steel filter mesh stands out as a versatile and indispensable component. When navigating the myriad of choices for filtration solutions, understanding the intricacies of steel filter mesh can significantly influence the success of your application, pushing your operations towards unprecedented efficiency and reliability.

As for trustworthiness, the reliability of steel filter mesh hinges on the assurance of consistent quality and performance. Trust begins with the sourcing of premium-grade raw materials, followed by rigorous quality control during each manufacturing phase. Leading authorities in the industry conduct extensive testing on parameters such as tensile strength, aperture size accuracy, and corrosion resistance. Certifications from recognized bodies further solidify this trust, guaranteeing that the steel filter mesh will perform optimally throughout its intended lifespan. Users' experiences with steel filter mesh often highlight its ease of maintenance and longevity, reducing long-term operational costs. Unlike other filtration media that may require frequent replacement, steel filter mesh can be cleaned and reused multiple times without degradation in performance. This not only reduces waste but also offers significant savings, especially for large-scale operations. To appreciate the full potential of steel filter mesh, consider its applications in air and liquid filtration systems. In HVAC systems, for example, stainless steel mesh filters ensure clean airflow without compromising on efficiency. Meanwhile, in water treatment facilities, the ability of steel meshes to withstand biochemical reactions and high flow rates makes them indispensable for purifying water streams, ensuring that communities receive safe and clean water. In conclusion, steel filter mesh embodies the pinnacle of engineering and material science, offering unmatched expertise, authority, and trustworthiness. Its adaptability across varying industries and application scenarios speaks to its innovative design and enduring reliability. When selecting steel filter mesh, it is crucial to partner with experienced manufacturers who not only understand your needs but also possess the expertise to provide solutions that propel your business forward, ensuring precision, reliability, and sustainability every step of the way.

As for trustworthiness, the reliability of steel filter mesh hinges on the assurance of consistent quality and performance. Trust begins with the sourcing of premium-grade raw materials, followed by rigorous quality control during each manufacturing phase. Leading authorities in the industry conduct extensive testing on parameters such as tensile strength, aperture size accuracy, and corrosion resistance. Certifications from recognized bodies further solidify this trust, guaranteeing that the steel filter mesh will perform optimally throughout its intended lifespan. Users' experiences with steel filter mesh often highlight its ease of maintenance and longevity, reducing long-term operational costs. Unlike other filtration media that may require frequent replacement, steel filter mesh can be cleaned and reused multiple times without degradation in performance. This not only reduces waste but also offers significant savings, especially for large-scale operations. To appreciate the full potential of steel filter mesh, consider its applications in air and liquid filtration systems. In HVAC systems, for example, stainless steel mesh filters ensure clean airflow without compromising on efficiency. Meanwhile, in water treatment facilities, the ability of steel meshes to withstand biochemical reactions and high flow rates makes them indispensable for purifying water streams, ensuring that communities receive safe and clean water. In conclusion, steel filter mesh embodies the pinnacle of engineering and material science, offering unmatched expertise, authority, and trustworthiness. Its adaptability across varying industries and application scenarios speaks to its innovative design and enduring reliability. When selecting steel filter mesh, it is crucial to partner with experienced manufacturers who not only understand your needs but also possess the expertise to provide solutions that propel your business forward, ensuring precision, reliability, and sustainability every step of the way.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024