2 月 . 04, 2025 05:57

Back to list

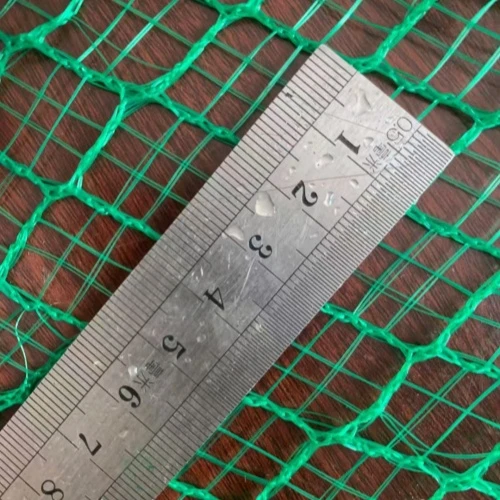

100% HDPE Agricultural Bird Proof Netting Knotted Heavy-Duty Bird Netting

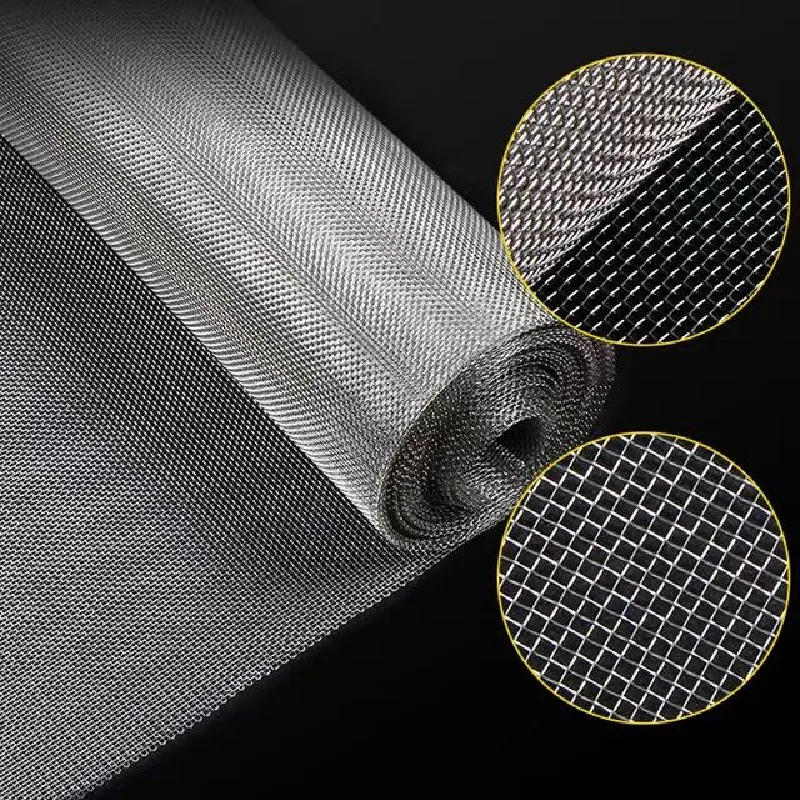

Stainless woven wire mesh, an essential component in a variety of industrial applications, offers unique qualities that set it apart in the world of materials engineering. This article delves into its multifaceted uses and advantages, aiming to provide a comprehensive understanding for professionals seeking reliable information supported by expertise, authority, and trustworthiness.

The expertise in producing stainless woven wire mesh lies in the meticulous selection and processing of stainless steel, along with precision weaving techniques that ensure uniformity and strength. As a result, manufacturers with a proven track record in the metallurgical industry add an authoritative voice to the product’s credibility. Clients can rely on these manufacturers, reinforced by certifications and industry standards, to provide materials that meet exacting specifications. Furthermore, the mesh's exceptional corrosion resistance is central to its widespread adoption across various markets. Whether it's exposure to harsh weather, saline environments, or industrial chemicals, stainless woven wire mesh reliably resists degradation, thereby maintaining its functionality and appearance over time. This enduring resilience supports professional claims of its trustworthiness and underscores its strong reputation in the field. In terms of sustainability, stainless woven wire mesh aligns with modern industry demands for environmentally friendly materials. It is 100% recyclable, which supports waste reduction and conservation of resources, making it a preferred choice for environmentally conscious projects. Professionals can rely on the ecological benefits of this material to meet both regulatory requirements and corporate social responsibility goals. In conclusion, stainless woven wire mesh is not just a material but a testament to high-performance engineering solutions. Its integration into various fields underscores its importance and affirms its position as an authoritative choice in material science. When sourced from reputable manufacturers, it represents a melding of experience, expertise, and credibility, promising reliability and superior performance across its applications. Specialists in diverse industries can trust stainless woven wire mesh for its proven strength, adaptability, and sustainability, making it a cornerstone material in both practical and innovative applications.

The expertise in producing stainless woven wire mesh lies in the meticulous selection and processing of stainless steel, along with precision weaving techniques that ensure uniformity and strength. As a result, manufacturers with a proven track record in the metallurgical industry add an authoritative voice to the product’s credibility. Clients can rely on these manufacturers, reinforced by certifications and industry standards, to provide materials that meet exacting specifications. Furthermore, the mesh's exceptional corrosion resistance is central to its widespread adoption across various markets. Whether it's exposure to harsh weather, saline environments, or industrial chemicals, stainless woven wire mesh reliably resists degradation, thereby maintaining its functionality and appearance over time. This enduring resilience supports professional claims of its trustworthiness and underscores its strong reputation in the field. In terms of sustainability, stainless woven wire mesh aligns with modern industry demands for environmentally friendly materials. It is 100% recyclable, which supports waste reduction and conservation of resources, making it a preferred choice for environmentally conscious projects. Professionals can rely on the ecological benefits of this material to meet both regulatory requirements and corporate social responsibility goals. In conclusion, stainless woven wire mesh is not just a material but a testament to high-performance engineering solutions. Its integration into various fields underscores its importance and affirms its position as an authoritative choice in material science. When sourced from reputable manufacturers, it represents a melding of experience, expertise, and credibility, promising reliability and superior performance across its applications. Specialists in diverse industries can trust stainless woven wire mesh for its proven strength, adaptability, and sustainability, making it a cornerstone material in both practical and innovative applications.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024