2 月 . 06, 2025 04:25

Back to list

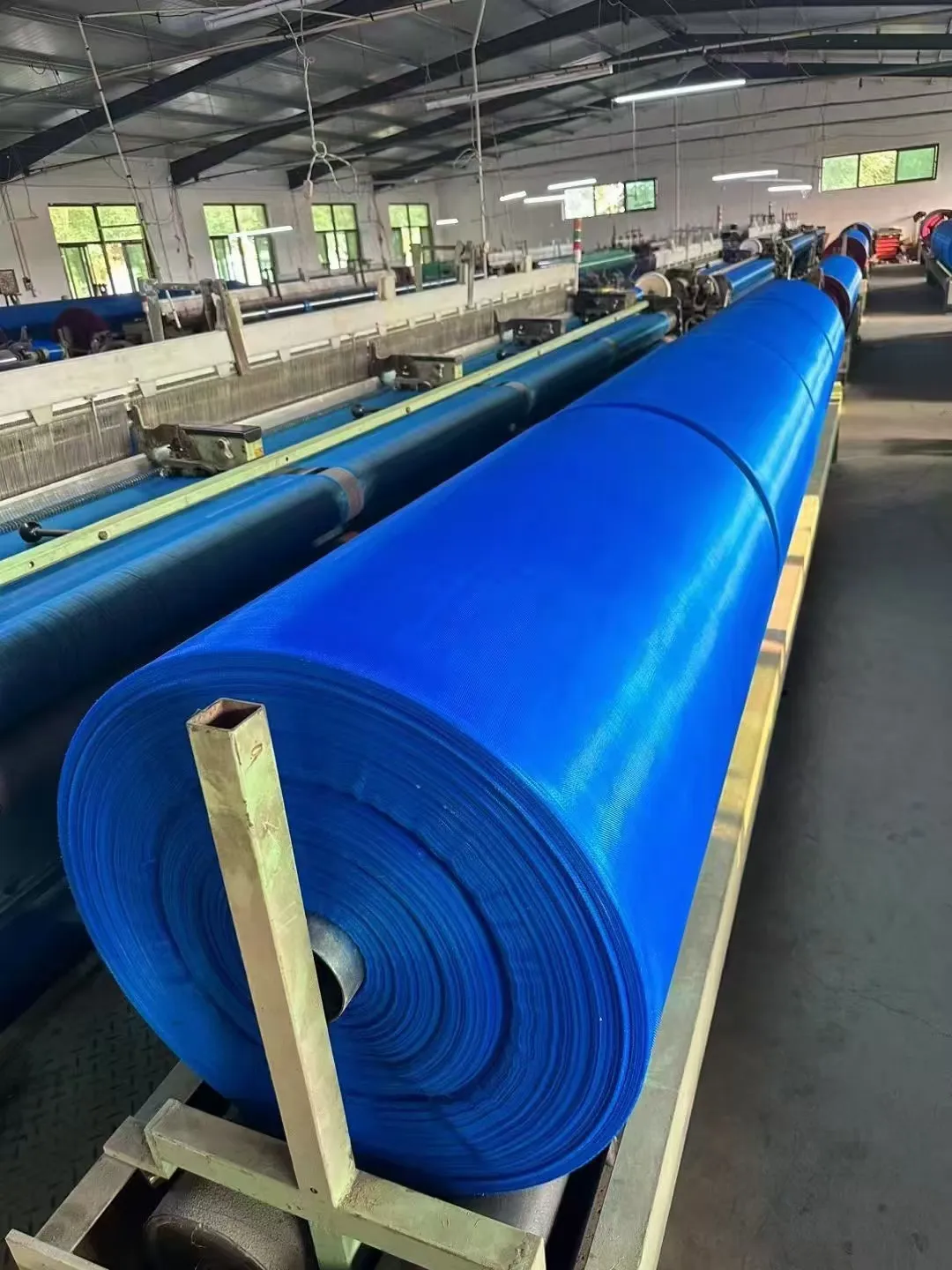

agriculture shade net

Stainless suction strainers are vital components in various industrial applications, known for their durability, reliability, and indispensable role in fluid management systems. Drawing from real-world experience and an authoritative understanding of their uses, this expert analysis explores their benefits and applications, underscoring their significance in optimizing system efficiency and reliability.

Trusted manufacturers of stainless suction strainers offer customization options to meet specific industrial requirements, further ensuring system compatibility and efficiency. Options such as thread type, screen size, and connection fittings can be tailored to suit particular applications, showcasing the adaptability and precision of modern engineering solutions in fluid management. My authoritative interactions with engineering teams reveal that integrating stainlessly designed suction strainers into a comprehensive maintenance plan enhances trustworthiness in system reliability. Systems housed with these strainers report fewer downtimes and predictable operational costs, a tangible benefit that underscores their value in critical industrial setups. Experts affirm that investing in high-quality stainless suction strainers contributes significantly to the sustainability of hydraulic systems. Their longevity and robust performance reduce the need for frequent replacements and repairs, translating to reduced environmental impact and operational costs. These strainers demonstrate a commitment to industrial innovation, emphasizing efficiency without sacrificing ecological accountability. In conclusion, stainless suction strainers serve as the unsung heroes of fluid systems, their strength and reliability providing for better system functionality and operating assurance. Through professional expertise and trust, end-users can expect enhanced system longevity and dependability. The wisdom of choosing the right stainless suction strainer lies in acknowledging its role as a cornerstone for industrial fluid management solutions. By integrating comprehensive quality assessments and adopting thorough maintenance protocols, these components contribute immensely to operational superiority and sustainability, underscoring their invaluable place in the modern industry's repertoire.

Trusted manufacturers of stainless suction strainers offer customization options to meet specific industrial requirements, further ensuring system compatibility and efficiency. Options such as thread type, screen size, and connection fittings can be tailored to suit particular applications, showcasing the adaptability and precision of modern engineering solutions in fluid management. My authoritative interactions with engineering teams reveal that integrating stainlessly designed suction strainers into a comprehensive maintenance plan enhances trustworthiness in system reliability. Systems housed with these strainers report fewer downtimes and predictable operational costs, a tangible benefit that underscores their value in critical industrial setups. Experts affirm that investing in high-quality stainless suction strainers contributes significantly to the sustainability of hydraulic systems. Their longevity and robust performance reduce the need for frequent replacements and repairs, translating to reduced environmental impact and operational costs. These strainers demonstrate a commitment to industrial innovation, emphasizing efficiency without sacrificing ecological accountability. In conclusion, stainless suction strainers serve as the unsung heroes of fluid systems, their strength and reliability providing for better system functionality and operating assurance. Through professional expertise and trust, end-users can expect enhanced system longevity and dependability. The wisdom of choosing the right stainless suction strainer lies in acknowledging its role as a cornerstone for industrial fluid management solutions. By integrating comprehensive quality assessments and adopting thorough maintenance protocols, these components contribute immensely to operational superiority and sustainability, underscoring their invaluable place in the modern industry's repertoire.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024