2 月 . 18, 2025 07:46

Back to list

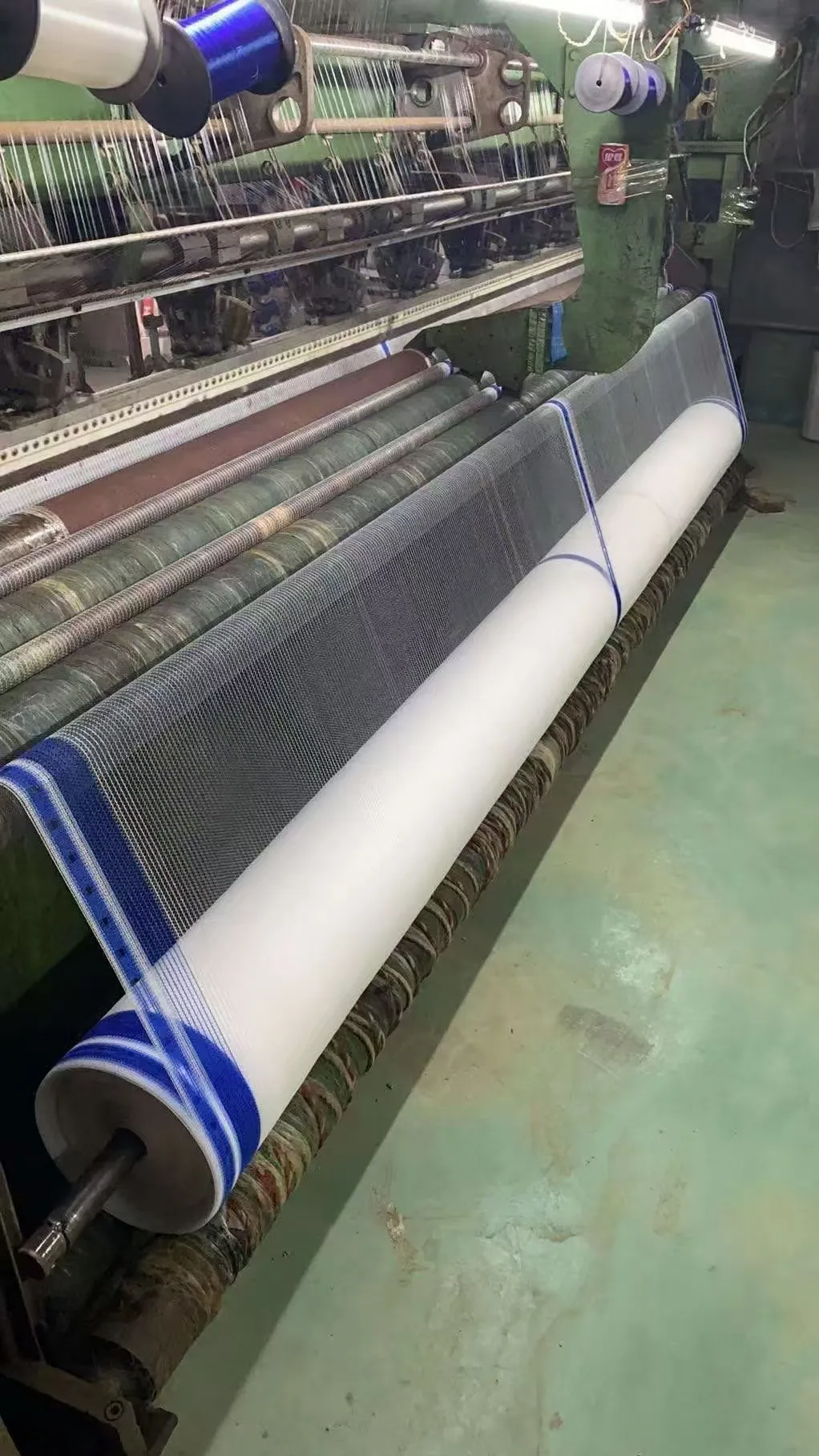

woven bird netting

Stainless steel woven wire mesh stands as a critical component in various industries, owing to its durability and versatility. As a professional in this realm, I've gathered insights and experiences over the years that highlight its profound benefits and applications, ensuring clients receive both quality and value.

Authoritativeness is further bolstered by the endorsements from numerous global industries that vouch for stainless steel woven wire mesh's capabilities. Whether implementing it in a high-pressure chemical environment or utilizing it in artistic architectural designs, the myriad endorsements from seasoned professionals speak to the material's reliability. Industry awards and certifications further bolster its reputation, establishing its place as a pivotal component in cutting-edge projects worldwide. Trustworthiness forms the backbone of any enduring client-manufacturer relationship. Reliable suppliers offer warranties and customer support that stand as a testament to the mesh's quality. Transparent sourcing of materials and ethical manufacturing practices ensure clients receive a product that not only performs exceptionally but also contributes to a sustainable future. This commitment to ethical practices has earned the trust of countless companies, solidifying stainless steel woven wire mesh as a reliable choice for myriad applications. In summary, stainless steel woven wire mesh represents a confluence of strength, functionality, and aesthetic potential. Its wide array of applications showcases its versatility, while the ongoing innovations in its crafting reflect the depth of expertise within the industry. Through real-world experience, professional expertise, authoritative endorsements, and a foundation of trustworthiness, stainless steel woven wire mesh remains an indispensable asset for industries aiming for excellence and durability.

Authoritativeness is further bolstered by the endorsements from numerous global industries that vouch for stainless steel woven wire mesh's capabilities. Whether implementing it in a high-pressure chemical environment or utilizing it in artistic architectural designs, the myriad endorsements from seasoned professionals speak to the material's reliability. Industry awards and certifications further bolster its reputation, establishing its place as a pivotal component in cutting-edge projects worldwide. Trustworthiness forms the backbone of any enduring client-manufacturer relationship. Reliable suppliers offer warranties and customer support that stand as a testament to the mesh's quality. Transparent sourcing of materials and ethical manufacturing practices ensure clients receive a product that not only performs exceptionally but also contributes to a sustainable future. This commitment to ethical practices has earned the trust of countless companies, solidifying stainless steel woven wire mesh as a reliable choice for myriad applications. In summary, stainless steel woven wire mesh represents a confluence of strength, functionality, and aesthetic potential. Its wide array of applications showcases its versatility, while the ongoing innovations in its crafting reflect the depth of expertise within the industry. Through real-world experience, professional expertise, authoritative endorsements, and a foundation of trustworthiness, stainless steel woven wire mesh remains an indispensable asset for industries aiming for excellence and durability.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024