2 月 . 20, 2025 07:28

Back to list

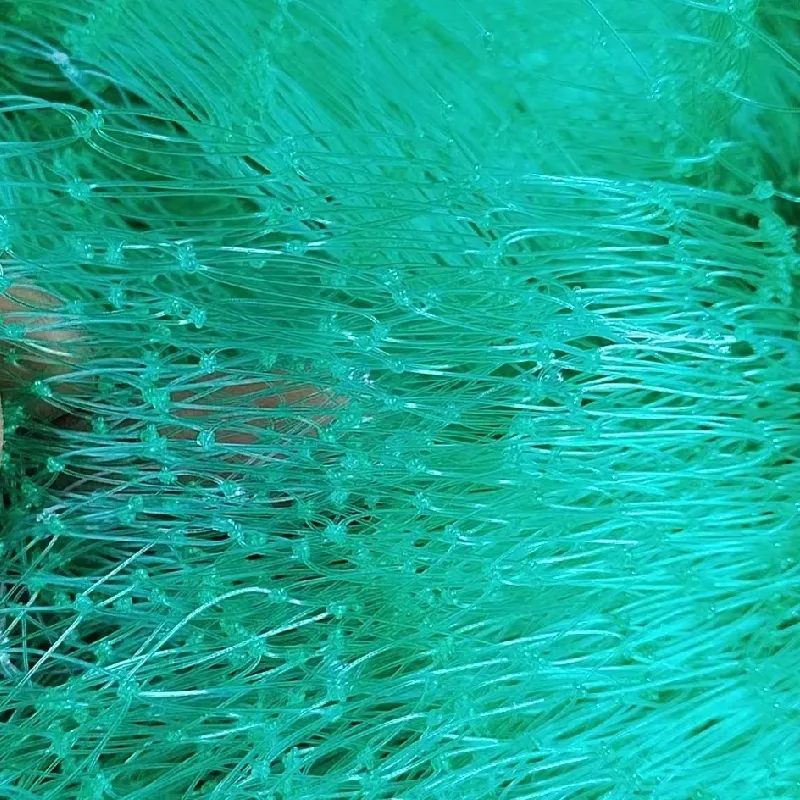

solar bird mesh

Navigating the intricate world of stainless steel mesh manufacturers can be an enlightening journey, especially when seeking high-quality products to meet stringent industrial needs. The stainless steel mesh industry stands as a cornerstone in numerous sectors, from construction to pharmaceuticals, thanks to its durability, versatility, and resistance to corrosion. Here’s a deep dive into what makes stainless steel mesh manufacturers excel and what you should consider when selecting the right partner for your needs.

Customer experience is another pillar of trustworthiness and authority in the sector. Top-tier manufacturers prioritize providing exceptional customer service—from the initial inquiry to after-sales support. This includes offering customization options to meet specific project requirements, comprehensive technical support, and timely delivery schedules. Manufacturers that maintain open lines of communication, and provide predictive maintenance and troubleshooting assistance, are highly valued. Moreover, pioneering manufacturers invest heavily in research and development. By fostering innovation, they not only enhance their product offerings but also continue to set industry benchmarks. Their R&D initiatives often focus on enhancing the durability, versatility, and functionality of stainless steel mesh, ensuring their products can meet evolving industrial demands. Finally, authoritative manufacturers uphold stringent quality control measures throughout their production process. This commitment is often demonstrated by obtaining and maintaining relevant certifications and accreditations which serve as a testament to their efficacy and adherence to high standards. These credentials should be easily accessible on their websites or available upon request, reflecting the manufacturers' commitment to transparency and customer assurance. Choosing the right stainless steel mesh manufacturer involves a consideration of their experience, expertise, and the value they place on building trust with their clients. With these factors in mind, industry professionals can partner with manufacturers who not only supply superior products but also enhance the overall operational efficiency and reliability of their industrial processes.

Customer experience is another pillar of trustworthiness and authority in the sector. Top-tier manufacturers prioritize providing exceptional customer service—from the initial inquiry to after-sales support. This includes offering customization options to meet specific project requirements, comprehensive technical support, and timely delivery schedules. Manufacturers that maintain open lines of communication, and provide predictive maintenance and troubleshooting assistance, are highly valued. Moreover, pioneering manufacturers invest heavily in research and development. By fostering innovation, they not only enhance their product offerings but also continue to set industry benchmarks. Their R&D initiatives often focus on enhancing the durability, versatility, and functionality of stainless steel mesh, ensuring their products can meet evolving industrial demands. Finally, authoritative manufacturers uphold stringent quality control measures throughout their production process. This commitment is often demonstrated by obtaining and maintaining relevant certifications and accreditations which serve as a testament to their efficacy and adherence to high standards. These credentials should be easily accessible on their websites or available upon request, reflecting the manufacturers' commitment to transparency and customer assurance. Choosing the right stainless steel mesh manufacturer involves a consideration of their experience, expertise, and the value they place on building trust with their clients. With these factors in mind, industry professionals can partner with manufacturers who not only supply superior products but also enhance the overall operational efficiency and reliability of their industrial processes.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024