2 月 . 03, 2025 02:59

Back to list

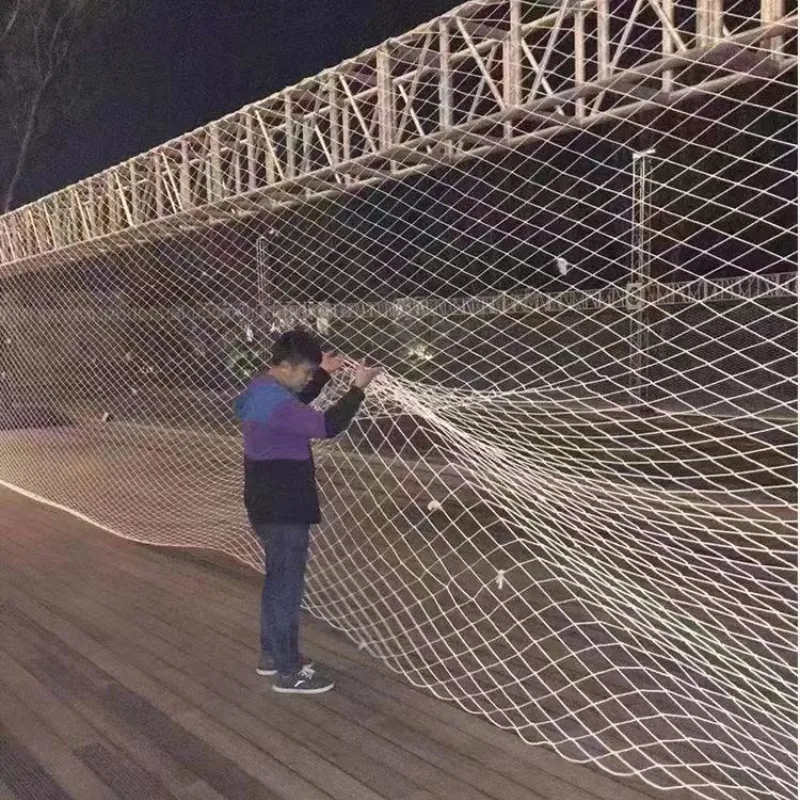

solar bird mesh

In the realm of industrial applications, stainless steel mesh conveyors have emerged as a pivotal innovation, ceaselessly redefining operational efficiency and durability. Crafted meticulously from high-grade stainless steel, these conveyors stand out not merely because of their robust material composition but also due to their unparalleled capability to withstand the rigorous demands of modern manufacturing environments.

Equipped with cutting-edge features, stainless steel mesh conveyors are often customized to meet specific operational requirements, reflecting the adaptable and forward-thinking approach of manufacturers. This customization can range from altering mesh sizes to accommodate different product types to integrating automated mechanisms that align with the technological advancements of Industry 4.0. Such modifications ensure that these conveyors not only meet current industrial demands but are also future-ready solutions poised to tackle forthcoming challenges in various sectors. Trustworthiness is inherently ingrained in the lifecycle of stainless steel mesh conveyors, backed by thorough quality assurance protocols. During production, each conveyor is subjected to rigorous testing against industry benchmarks to ensure compliance with safety and operational standards. This rigorous attention to quality cements their reputation as reliable and long-lasting machinery components in the eyes of industrial operators. Moreover, stainless steel mesh conveyors are supported by comprehensive after-sales service from manufacturers, which includes maintenance, technical support, and timely updates on the latest technological advancements. This commitment to customer satisfaction and support fosters trust and long-term partnerships between providers and users, reinforcing the conveyors' standing as trusted solutions in various industrial processes. In conclusion, stainless steel mesh conveyors represent a harmonious blend of innovation, durability, and operational efficiency. Their resistance to environmental and chemical challenges, combined with the ability to be fine-tuned to specific industry needs, positions them as a pivotal asset in the contemporary industrial landscape. As industries continually evolve, the role of stainless steel mesh conveyors is set to expand, driven by their unmatched performance and reliability that stand the test of time.

Equipped with cutting-edge features, stainless steel mesh conveyors are often customized to meet specific operational requirements, reflecting the adaptable and forward-thinking approach of manufacturers. This customization can range from altering mesh sizes to accommodate different product types to integrating automated mechanisms that align with the technological advancements of Industry 4.0. Such modifications ensure that these conveyors not only meet current industrial demands but are also future-ready solutions poised to tackle forthcoming challenges in various sectors. Trustworthiness is inherently ingrained in the lifecycle of stainless steel mesh conveyors, backed by thorough quality assurance protocols. During production, each conveyor is subjected to rigorous testing against industry benchmarks to ensure compliance with safety and operational standards. This rigorous attention to quality cements their reputation as reliable and long-lasting machinery components in the eyes of industrial operators. Moreover, stainless steel mesh conveyors are supported by comprehensive after-sales service from manufacturers, which includes maintenance, technical support, and timely updates on the latest technological advancements. This commitment to customer satisfaction and support fosters trust and long-term partnerships between providers and users, reinforcing the conveyors' standing as trusted solutions in various industrial processes. In conclusion, stainless steel mesh conveyors represent a harmonious blend of innovation, durability, and operational efficiency. Their resistance to environmental and chemical challenges, combined with the ability to be fine-tuned to specific industry needs, positions them as a pivotal asset in the contemporary industrial landscape. As industries continually evolve, the role of stainless steel mesh conveyors is set to expand, driven by their unmatched performance and reliability that stand the test of time.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024