Durable Stainless Steel Mesh for Enhanced Strength and Versatility in Various Applications

Understanding Stainless Steel Mesh Versatility and Applications

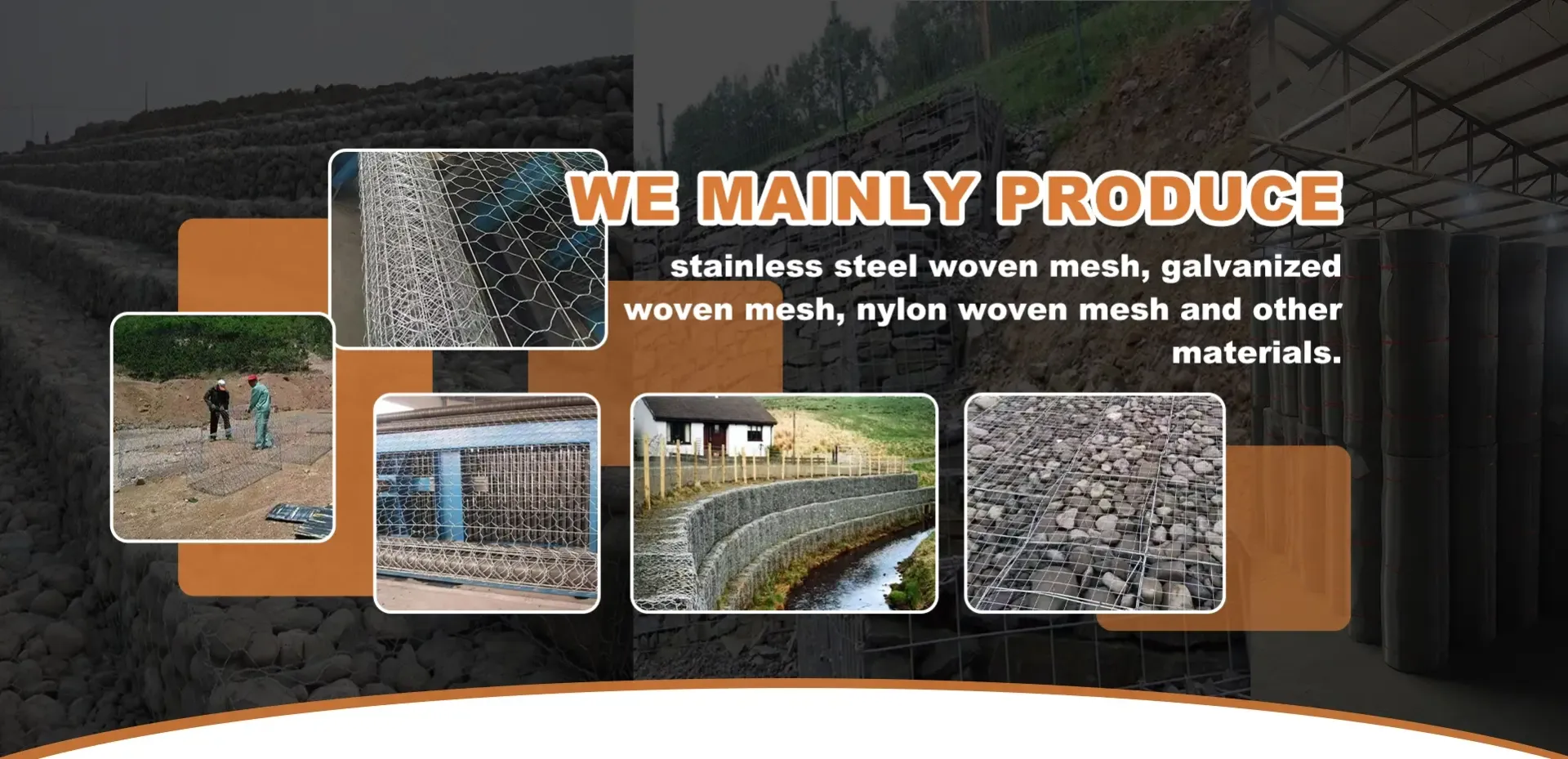

Stainless steel mesh is an industrial material renowned for its unique combination of strength, durability, and resistance to corrosion. These properties make it an ideal choice for a wide array of applications across various industries, ranging from construction to food processing. This article explores the characteristics, production methods, and diverse applications of stainless steel mesh, illustrating why it is a favored material in today's manufacturing and construction sectors.

Characteristics of Stainless Steel Mesh

One of the primary features of stainless steel mesh is its corrosion resistance. Stainless steel is an alloy that typically contains chromium, which forms a protective layer of chromium oxide on the surface. This layer prevents oxidation, making the mesh suitable for environments exposed to moisture and chemicals. As a result, stainless steel mesh can maintain its integrity over time, even in harsh conditions.

In addition to corrosion resistance, stainless steel mesh is also characterized by its high tensile strength. This strength ensures that the mesh can withstand significant loads without deforming, making it ideal for structural applications. Stainless steel’s ability to endure extreme temperatures further expands its utility, as it remains stable and retains its properties even when exposed to heat or cold.

Production Methods of Stainless Steel Mesh

The production of stainless steel mesh involves various methods, each suited to different mesh specifications and application requirements. The most common manufacturing processes include weaving, welding, and netting.

1. Weaving Stainless steel wires are woven together to create mesh sheets with varying apertures (the opening sizes in the mesh). This method allows for precise control over mesh density, making it adaptable for different filtration and screening processes.

2. Welding In this process, the wires are electrically welded at their intersections, producing a more robust and uniform mesh. Welded stainless steel mesh is particularly valued in applications that require a strong and rigid product, such as fencing and security screens.

3. Netting This method involves the use of a net-like structure that is typically more flexible than woven or welded varieties. It is often used in applications like horticulture for plant supports and insect barriers.

stainless steel mesh

Regardless of the production method, the quality of stainless steel mesh is heavily influenced by the grade of stainless steel used. Various grades, such as 304 and 316, are chosen based on their specific properties and suitability for particular environments.

Applications of Stainless Steel Mesh

The versatility of stainless steel mesh leads to its application in numerous fields

1. Construction In construction, stainless steel mesh is commonly used for reinforcing concrete. It provides structural integrity and prevents cracking, enhancing the longevity of buildings and infrastructure.

2. Filtration and Separation In industries like food processing, chemical manufacturing, and water treatment, stainless steel mesh is used for filtration applications. Its fine openings allow it to effectively separate solids from liquids or gases, making it crucial in maintaining product purity and efficiency.

3. Security and Fencing Stainless steel mesh is also utilized in security applications, where it acts as a barrier while allowing visibility and airflow. It's often used in fencing, gates, and as enclosures for industrial sites or private properties.

4. Architectural Design In contemporary architecture, stainless steel mesh serves aesthetic and functional purposes. It can be used in facades, sunshades, and decorative elements, providing a modern look while ensuring structural functionality.

5. Industrial Applications Various industries leverage stainless steel mesh for applications such as sieving, screening, and reinforcement. Its reliability and strength make it suitable for heavy-duty tasks in manufacturing and processing environments.

Conclusion

Stainless steel mesh exemplifies a remarkable material that combines practicality with versatility. From its corrosion resistance and strength to its range of applications, it stands out as a solution across various industries. Whether you're involved in construction, food processing, or security, understanding the benefits and uses of stainless steel mesh can lead to better decision-making in material selection and application. As technology progresses, the development of new stainless steel mesh products is likely to enhance its capabilities and expand its utility even further in the future.

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024