2 月 . 20, 2025 01:51

Back to list

stainless steel gauze mesh

Exploring the Versatile World of Stainless Steel Gauze Mesh A Comprehensive Insight

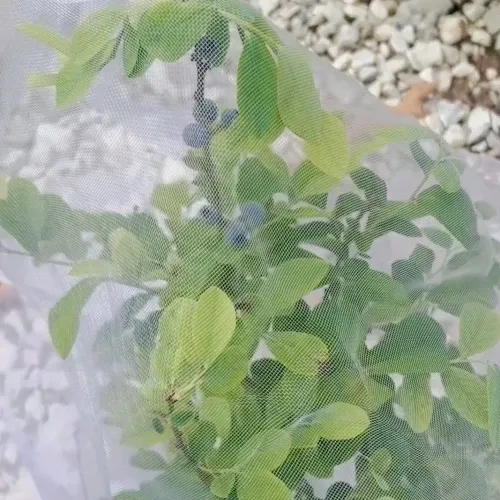

One of the most compelling aspects of stainless steel gauze mesh lies in its authoritativeness within its application domains. Leading architects and engineers consistently advocate for its use in construction projects due to its aesthetic appeal and functional benefits. The mesh can be fashioned into sophisticated facades or used as balustrade infills, offering both form and function. Its sleek appearance brings modern elegance, while its strength and durability fulfill the practical demands of structural engineering. In the realm of trusted applications, stainless steel gauze mesh shines in medical and food processing industries where hygiene and cleanliness are paramount. The non-reactive nature of stainless steel ensures that there are no contaminations, making it an ideal barrier or filtration medium in environments that demand the highest standards of cleanliness. Regulatory bodies often endorse stainless steel for such uses, underscoring the trust it commands within these precision-driven fields. Aside from its industrial applications, stainless steel gauze mesh has found its way into the lives of consumers, recognized for its practicality and durability in everyday items. From window screens that offer protection against insects without obstructing airflow, to advanced culinary tools designed for straining and sieving, its utility is undeniable. As consumers increasingly seek long-lasting, high-quality products, stainless steel gauze mesh consistently meets those expectations with its proven reliability and performance. In summary, stainless steel gauze mesh is an indispensable material that merges practicality with ingenuity across various domains. Its unmatched durability, combined with versatile configurations, allows it to serve diverse applications, exuding expertise and authority in each use. Trusted for its integrity and performance, it remains a preferred choice for professionals and consumers alike, embodying the pinnacle of modern material science.

One of the most compelling aspects of stainless steel gauze mesh lies in its authoritativeness within its application domains. Leading architects and engineers consistently advocate for its use in construction projects due to its aesthetic appeal and functional benefits. The mesh can be fashioned into sophisticated facades or used as balustrade infills, offering both form and function. Its sleek appearance brings modern elegance, while its strength and durability fulfill the practical demands of structural engineering. In the realm of trusted applications, stainless steel gauze mesh shines in medical and food processing industries where hygiene and cleanliness are paramount. The non-reactive nature of stainless steel ensures that there are no contaminations, making it an ideal barrier or filtration medium in environments that demand the highest standards of cleanliness. Regulatory bodies often endorse stainless steel for such uses, underscoring the trust it commands within these precision-driven fields. Aside from its industrial applications, stainless steel gauze mesh has found its way into the lives of consumers, recognized for its practicality and durability in everyday items. From window screens that offer protection against insects without obstructing airflow, to advanced culinary tools designed for straining and sieving, its utility is undeniable. As consumers increasingly seek long-lasting, high-quality products, stainless steel gauze mesh consistently meets those expectations with its proven reliability and performance. In summary, stainless steel gauze mesh is an indispensable material that merges practicality with ingenuity across various domains. Its unmatched durability, combined with versatile configurations, allows it to serve diverse applications, exuding expertise and authority in each use. Trusted for its integrity and performance, it remains a preferred choice for professionals and consumers alike, embodying the pinnacle of modern material science.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024