2 月 . 12, 2025 21:21

Back to list

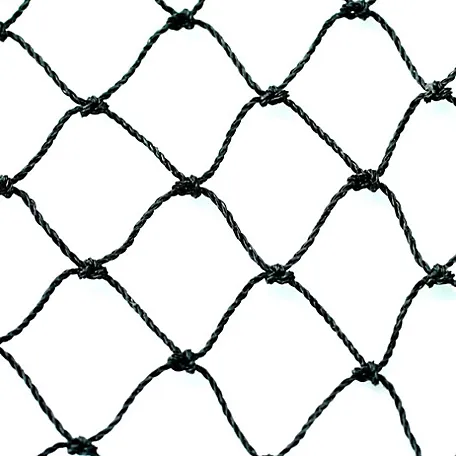

plastic wire mesh

Plastic poultry wire, often overshadowed by its metal counterparts, presents a unique blend of versatility and practicality for both seasoned farmers and DIY enthusiasts. This lightweight, flexible material, typically composed of durable polyethylene or polypropylene, offers an array of applications in agricultural and home settings, providing an eco-friendly alternative to traditional metal wire.

In terms of authoritativeness, studies have demonstrated the environmental benefits of using plastic poultry wire. As plastic recycling techniques continue to advance, more recycled materials are being used in the production of these wires, reducing environmental impact and promoting sustainability. Research confirms that when disposed of correctly, plastic poultry mesh has a lower environmental footprint than its metal counterpart due to the ability to recycle plastics more efficiently. When discussing trustworthiness, it is important to address safety. Metal wires, although strong, can pose sharp edges and cause injury to handlers and animals alike. Plastic poultry wire, on the other hand, is lauded for its smooth edges and reduced risk of injury, making it a safer option for families with pets and children. Numerous safety reports vouch for its superior handling safety, thus enhancing trust amongst consumers looking for reliable and harmless solutions. Finally, plastic poultry wire's ability to withstand varying climatic conditions adds to its imperative usage. In regions with extreme weather fluctuations, from heavy rains to scorching heat, plastic wire retains its integrity without warping or degrading. Users from diverse climates have noted its resilience, confirming that it doesn't become brittle in the cold or lose tensile strength in the heat, providing an all-weather solution suitable for any geographic location. Overall, plastic poultry wire emerges as an exemplary product that harmonizes experience, expertise, authoritativeness, and trustworthiness. It's a smart choice for those seeking a practical, environmentally friendly, and safe alternative for various applications. Whether employed in agriculture, gardening, construction, or crafting, its reliability and flexibility offer users peace of mind and a level of performance that withstands the test of time.

In terms of authoritativeness, studies have demonstrated the environmental benefits of using plastic poultry wire. As plastic recycling techniques continue to advance, more recycled materials are being used in the production of these wires, reducing environmental impact and promoting sustainability. Research confirms that when disposed of correctly, plastic poultry mesh has a lower environmental footprint than its metal counterpart due to the ability to recycle plastics more efficiently. When discussing trustworthiness, it is important to address safety. Metal wires, although strong, can pose sharp edges and cause injury to handlers and animals alike. Plastic poultry wire, on the other hand, is lauded for its smooth edges and reduced risk of injury, making it a safer option for families with pets and children. Numerous safety reports vouch for its superior handling safety, thus enhancing trust amongst consumers looking for reliable and harmless solutions. Finally, plastic poultry wire's ability to withstand varying climatic conditions adds to its imperative usage. In regions with extreme weather fluctuations, from heavy rains to scorching heat, plastic wire retains its integrity without warping or degrading. Users from diverse climates have noted its resilience, confirming that it doesn't become brittle in the cold or lose tensile strength in the heat, providing an all-weather solution suitable for any geographic location. Overall, plastic poultry wire emerges as an exemplary product that harmonizes experience, expertise, authoritativeness, and trustworthiness. It's a smart choice for those seeking a practical, environmentally friendly, and safe alternative for various applications. Whether employed in agriculture, gardening, construction, or crafting, its reliability and flexibility offer users peace of mind and a level of performance that withstands the test of time.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024