2 月 . 10, 2025 09:12

Back to list

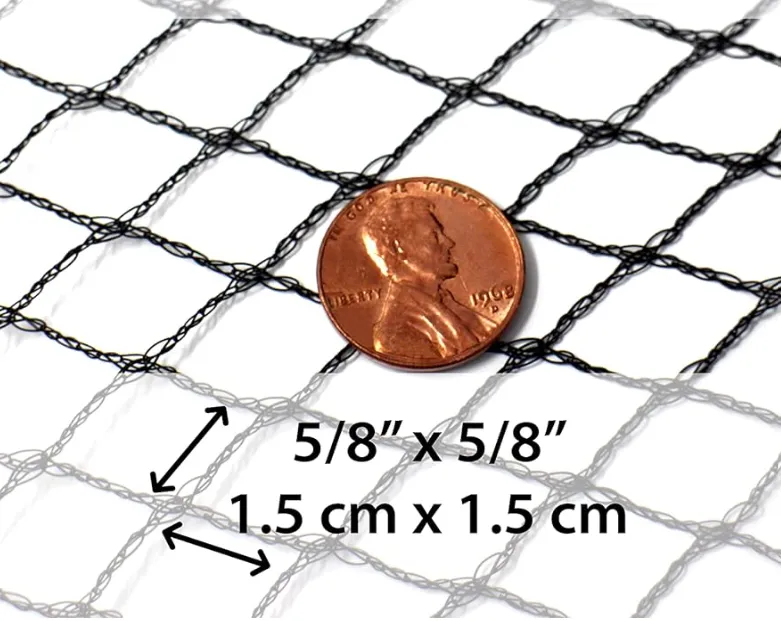

nylon netting mesh

In the dynamic world of industrial textiles, nylon netting mesh stands out as a versatile and indispensable material. Its adaptability lends itself to a wide range of applications, from agriculture to fashion, underscoring its reputation as a product of choice across various sectors.

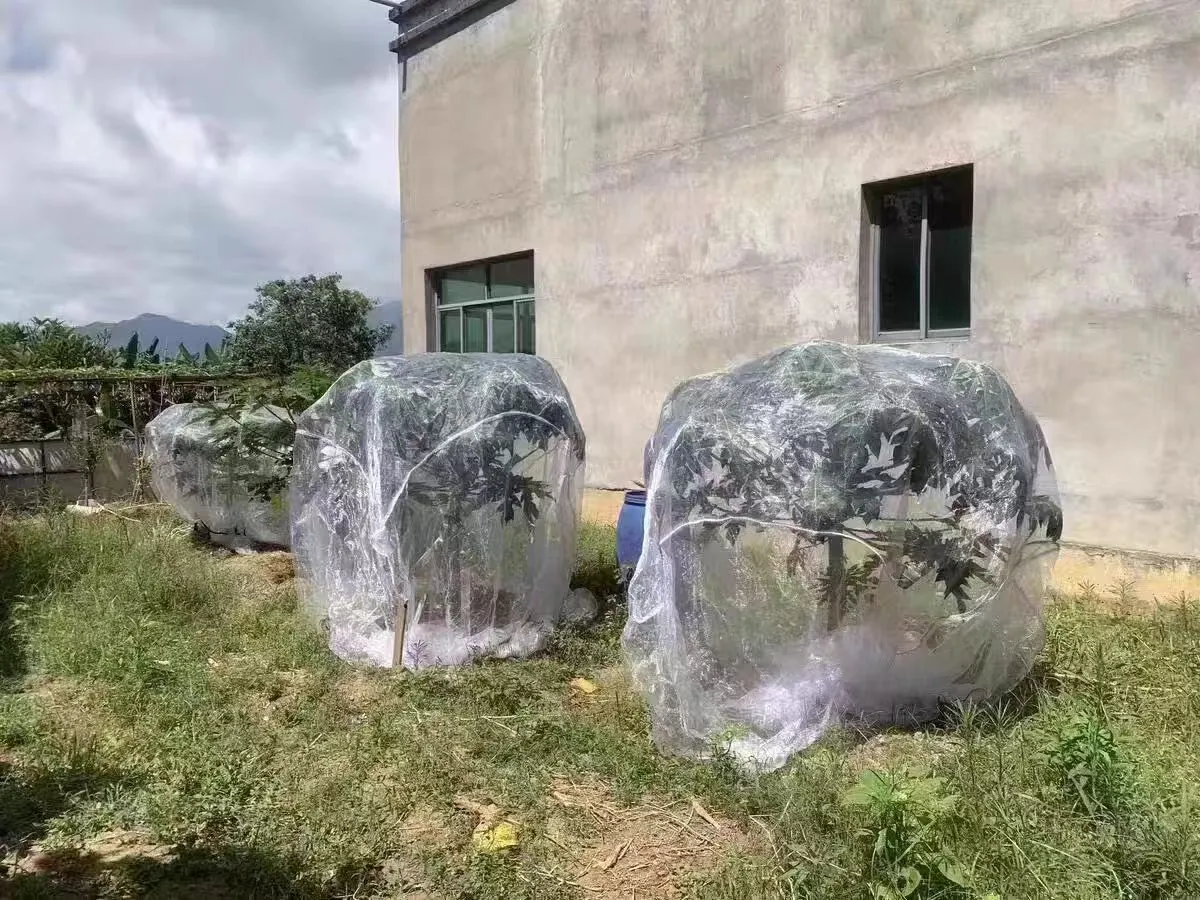

Trust is a significant factor when selecting materials for industrial use, and nylon netting mesh does not disappoint. Its long-standing presence in the market is a testament to its reliability and effectiveness. Companies that specialize in producing this mesh adhere to strict regulatory compliance, further bolstering consumer confidence. Clients benefit from a product that has been vetted by authoritative bodies, assuring them of its safety and efficacy. Moreover, real-world experiences offer insightful testimony to the mesh’s capabilities. Farmers who have switched to nylon netting report a significant reduction in crop damage and loss, attributing this to the mesh’s robust barrier against pests. In architectural applications, designers employ this mesh for tensile structures, where its lightweight and flexible nature allows for creative yet practical solutions. These case studies reflect the material’s versatility and effectiveness in real-world scenarios. In the realm of fashion, nylon netting mesh continues to inspire creative designs due to its sheer adaptability and aesthetic appeal. Fashion designers incorporate the mesh into their collections, providing texture and structural elements that are both functional and visually striking. This evidences the material’s cross-industry appeal, highlighting its multifaceted use cases. Nylon netting mesh, therefore, stands as a paragon of industrial textile innovation. Its widespread application, coupled with a robust foundation of expertise and authority, solidifies its position as a trusted material. In an era where safety and sustainability dictate material choice, nylon netting offers a compelling option that does not compromise on quality or performance. As industries continue to evolve, the demand for such reliable and adaptive materials will only grow, making nylon netting mesh a staple in industrial and creative applications alike.

Trust is a significant factor when selecting materials for industrial use, and nylon netting mesh does not disappoint. Its long-standing presence in the market is a testament to its reliability and effectiveness. Companies that specialize in producing this mesh adhere to strict regulatory compliance, further bolstering consumer confidence. Clients benefit from a product that has been vetted by authoritative bodies, assuring them of its safety and efficacy. Moreover, real-world experiences offer insightful testimony to the mesh’s capabilities. Farmers who have switched to nylon netting report a significant reduction in crop damage and loss, attributing this to the mesh’s robust barrier against pests. In architectural applications, designers employ this mesh for tensile structures, where its lightweight and flexible nature allows for creative yet practical solutions. These case studies reflect the material’s versatility and effectiveness in real-world scenarios. In the realm of fashion, nylon netting mesh continues to inspire creative designs due to its sheer adaptability and aesthetic appeal. Fashion designers incorporate the mesh into their collections, providing texture and structural elements that are both functional and visually striking. This evidences the material’s cross-industry appeal, highlighting its multifaceted use cases. Nylon netting mesh, therefore, stands as a paragon of industrial textile innovation. Its widespread application, coupled with a robust foundation of expertise and authority, solidifies its position as a trusted material. In an era where safety and sustainability dictate material choice, nylon netting offers a compelling option that does not compromise on quality or performance. As industries continue to evolve, the demand for such reliable and adaptive materials will only grow, making nylon netting mesh a staple in industrial and creative applications alike.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024