2 月 . 08, 2025 00:49

Back to list

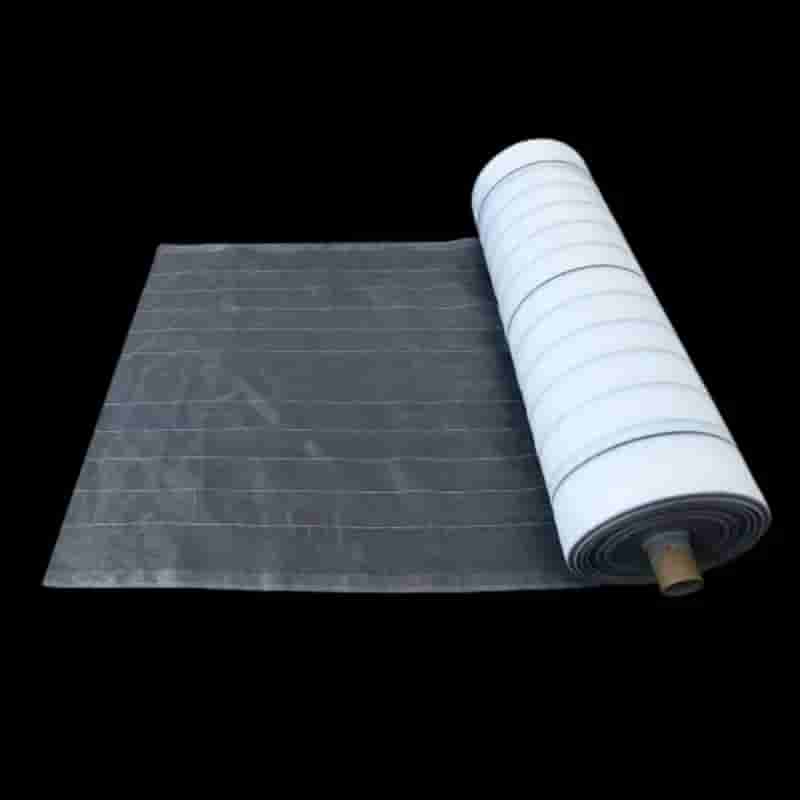

nylon net price

Understanding the nuances of nylon net pricing requires a blend of industry expertise, firsthand experience, and an appreciation for market dynamics. Nylon nets have become integral across a variety of industries, from fishing and agriculture to construction and industrial applications. As an authoritative figure in the nylon net sector, I aim to provide insightful perspectives that will help you navigate the intricacies of pricing, quality, and demand.

Another critical factor to consider is the intended application of nylon nets. For instance, farmers looking to use nets for crop protection may prioritize different qualities than a construction company needing nets for safety purposes. Thoroughly matching product specifications to the intended use can provide better value for money, even if it requires a higher initial investment. Market demands play a pivotal role in determining price strategies as well. Seasonal fluctuations can lead to varying demands, which in turn influence prices. The fishing industry, for example, sees different patterns of nylon net pricing based on fishing seasons and marine regulations. Maintaining a reputable position in the nylon net market involves ongoing research and adaptation. As technological advances continue to enhance the properties of nylon nets, staying abreast of these developments can assist in making well-informed purchasing decisions. Careful consideration of the production location is also essential. Production in regions with lower labor costs can lead to reduced prices, but potential buyers should weigh the quality and ethical implications. Partnering with manufacturers who adhere to high labor and environmental standards supports long-term sustainability and brand reputation. Ultimately, navigating the nylon net market with proficiency involves understanding these various elements and leveraging proven expertise. The insights offered here are designed to empower professionals engaging with nylon net products, providing a clear, authoritative roadmap for making informed pricing decisions that are both economically sound and strategically robust.

Another critical factor to consider is the intended application of nylon nets. For instance, farmers looking to use nets for crop protection may prioritize different qualities than a construction company needing nets for safety purposes. Thoroughly matching product specifications to the intended use can provide better value for money, even if it requires a higher initial investment. Market demands play a pivotal role in determining price strategies as well. Seasonal fluctuations can lead to varying demands, which in turn influence prices. The fishing industry, for example, sees different patterns of nylon net pricing based on fishing seasons and marine regulations. Maintaining a reputable position in the nylon net market involves ongoing research and adaptation. As technological advances continue to enhance the properties of nylon nets, staying abreast of these developments can assist in making well-informed purchasing decisions. Careful consideration of the production location is also essential. Production in regions with lower labor costs can lead to reduced prices, but potential buyers should weigh the quality and ethical implications. Partnering with manufacturers who adhere to high labor and environmental standards supports long-term sustainability and brand reputation. Ultimately, navigating the nylon net market with proficiency involves understanding these various elements and leveraging proven expertise. The insights offered here are designed to empower professionals engaging with nylon net products, providing a clear, authoritative roadmap for making informed pricing decisions that are both economically sound and strategically robust.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024