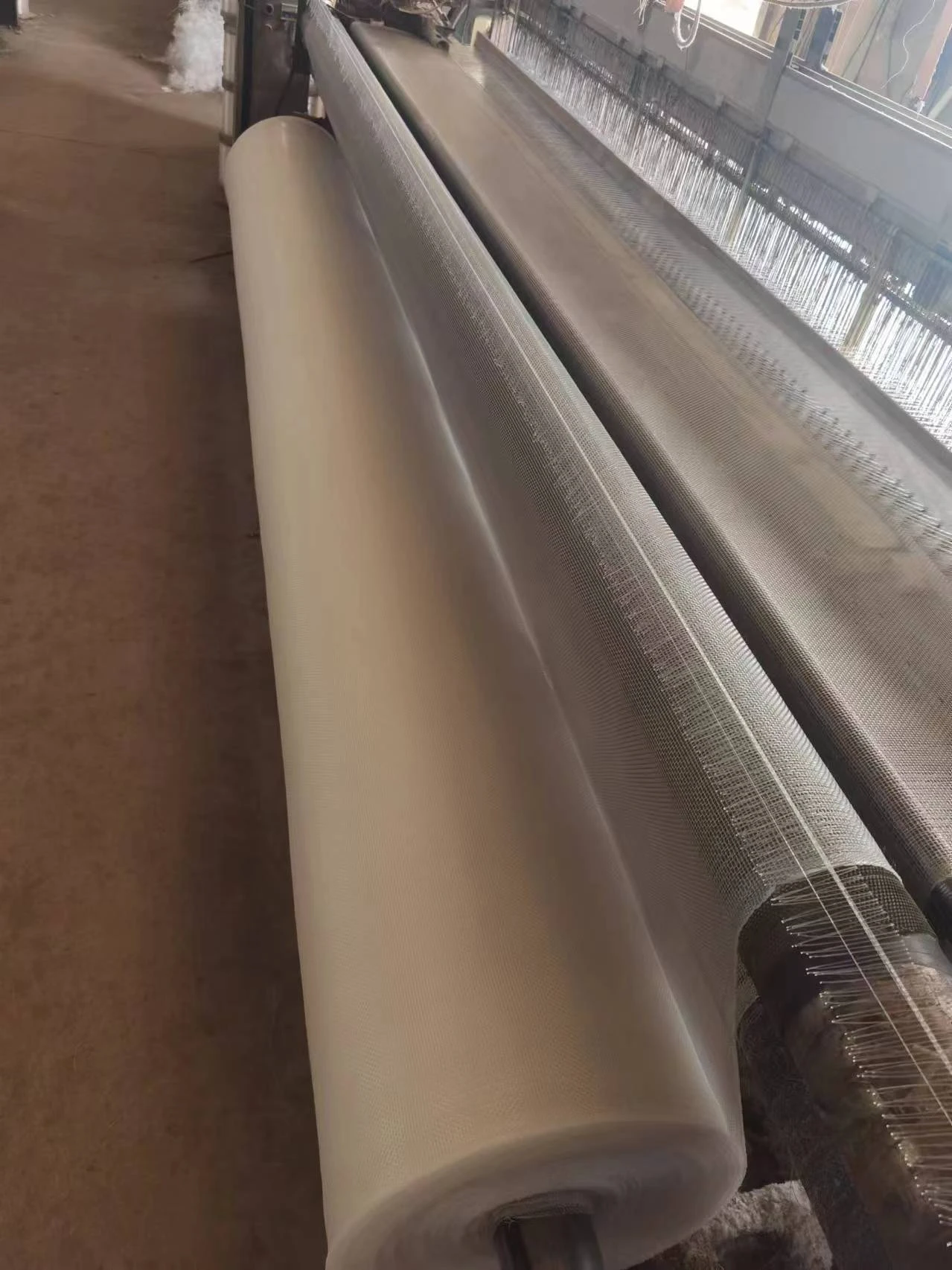

nylon micron mesh

Exploring Nylon Micron Mesh Versatility and Applications

Nylon micron mesh is a specialized type of filter material made from nylon, a synthetic polymer known for its durability, flexibility, and resistance to various chemicals. The term micron refers to the size of the openings in the mesh, which can be precisely controlled during manufacturing, allowing for a wide range of filtration distinctions. Depending on the application, nylon micron mesh can range from a few microns in size to larger openings suitable for various purposes. This article explores the properties, benefits, and diverse applications of nylon micron mesh in different industries.

Properties of Nylon Micron Mesh

One of the standout qualities of nylon micron mesh is its excellent mechanical strength. Nylon fibers are known for their ability to withstand physical stress, which makes the mesh durable and long-lasting. This durability is essential in applications that require frequent handling or exposure to harsh environments.

Another key property is its resistance to chemicals. Nylon is generally resilient against many acids, greases, and solvents, which allows the mesh to be used in industrial settings without significant degradation. Moreover, nylon micron mesh is lightweight and flexible, providing ease of use in various applications.

Nylon micron mesh is also hydrophobic, which means it typically repels water. However, it can be treated or woven in a way that allows for specific filtration applications where water permeability is required. This versatility makes nylon micron mesh an appealing choice for many filtering processes.

Benefits of Using Nylon Micron Mesh

The advantages of using nylon micron mesh extend beyond its physical properties. Its fine filtration capabilities are central to its appeal. The precise control over opening sizes allows for the separation of particles based on specific requirements, ranging from very fine particulates in laboratory environments to larger particles in industrial applications.

The material is also highly customizable. Manufacturers can produce nylon micron mesh in various configurations, including different weave patterns, thicknesses, and sizes, to suit specific needs. This customization allows businesses to optimize their filtering processes and achieve desired outcomes more efficiently.

nylon micron mesh

Additionally, nylon micron mesh is resistant to mold and mildew, which is particularly beneficial in applications such as food processing, where hygiene standards are paramount. Its ease of cleaning and maintenance further enhances its viability in settings where clean conditions are critical.

Applications of Nylon Micron Mesh

The applications of nylon micron mesh are vast and varied, spanning several industries. In food and beverage, it is often used for filtering liquids, such as juice or beer, ensuring that unwanted particles are removed while allowing the product to flow freely. Its ability to maintain hygiene standards makes it invaluable in this sector.

In the pharmaceutical industry, nylon micron mesh is instrumental for filtration during the manufacturing of drugs. It ensures that contaminants are filtered out, maintaining the purity and effectiveness of the final product. The mesh can also be employed in laboratory settings to ensure precise sampling and test results.

The chemical processing industry also benefits from nylon micron mesh. It is used in the filtration of chemicals, solvents, and oils, allowing for the efficient separation of particles and by-products during processing. This contributes to smoother operations and improved product quality.

Furthermore, in environmental applications, nylon micron mesh can be utilized for water treatment processes. Its fine filtration capabilities are essential for removing impurities and pollutants, contributing to cleaner water systems.

Conclusion

Nylon micron mesh serves as an indispensable material across various sectors due to its unique properties, benefits, and broad applications. Its durability, chemical resistance, and fine filtration capabilities make it an ideal choice for businesses aiming to enhance their operational efficiency and product quality. As industries continue to innovate and seek improved filtration solutions, the relevance of nylon micron mesh is expected to grow, solidifying its place as a fundamental component in modern engineering and manufacturing processes. Whether in food safety, pharmaceuticals, or environmental protection, nylon micron mesh is set to play a crucial role in the future, enabling cleaner, safer, and more efficient outcomes across the board.

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024