1 月 . 28, 2025 06:00

Back to list

Thickened Nylon Mesh

Mining screen mesh plays an indispensable role in the mining industry, acting as a critical filter that separates valuable minerals from waste. With ever-evolving technology and industry requirements, selecting the right mining screen mesh can mean the difference between success and inefficiency. Here, we delve into the essential aspects of mining screen mesh, drawing upon years of experience and expert insight to guide your choice.

Another core pillar is Trustworthiness. For those new to exploring screen mesh options, it’s imperative to engage with manufacturers and suppliers who boast a proven track record. Reputable companies offer warranties, clear documentation, and adhere to international safety and quality standards. Their offerings aren’t just products; they provide peace of mind, knowing that the equipment will withstand the rigors of your specific mining environment. Yet, what underscores both Authoritativeness and Trustworthiness is real-world feedback. Mining operators should seek out case studies and testimonials that detail how particular screen meshes have functioned in comparable industries or conditions. Firsthand accounts are invaluable not only as a confidence gauge but as a practical predictor of performance in situ. Innovative trends in the field are pointing towards self-cleaning meshes, which incorporate design elements that help reduce blinding and clogging. These meshes leverage the expertise of materials science, incorporating coatings or specialized weaving to naturally shed materials that tend to cake and obstruct traditional meshes. The result is a drastic reduction in downtime for cleaning and maintenance, allowing operations to maintain peak performance levels. Finally, in considering the economic aspect, investing in premium screen mesh might initially seem daunting, but the return on investment through enhanced durability, reduced maintenance, and improved efficiency can far outweigh the upfront costs. This economic prudence is a cornerstone of strategic thinking in mining operations today. In conclusion, the world of mining screen mesh is complex and requires a deep understanding of both the product and the operational environment. From material selection to customization, from engaging reputable suppliers to integrating cutting-edge technology, every step must be orchestrated with precision and care. By aligning these aspects with the values of Experience, Expertise, Authoritativeness, and Trustworthiness, mining operations not only ensure they are equipped with the optimal tool but also position themselves for sustainable success in an industry that demands no less.

Another core pillar is Trustworthiness. For those new to exploring screen mesh options, it’s imperative to engage with manufacturers and suppliers who boast a proven track record. Reputable companies offer warranties, clear documentation, and adhere to international safety and quality standards. Their offerings aren’t just products; they provide peace of mind, knowing that the equipment will withstand the rigors of your specific mining environment. Yet, what underscores both Authoritativeness and Trustworthiness is real-world feedback. Mining operators should seek out case studies and testimonials that detail how particular screen meshes have functioned in comparable industries or conditions. Firsthand accounts are invaluable not only as a confidence gauge but as a practical predictor of performance in situ. Innovative trends in the field are pointing towards self-cleaning meshes, which incorporate design elements that help reduce blinding and clogging. These meshes leverage the expertise of materials science, incorporating coatings or specialized weaving to naturally shed materials that tend to cake and obstruct traditional meshes. The result is a drastic reduction in downtime for cleaning and maintenance, allowing operations to maintain peak performance levels. Finally, in considering the economic aspect, investing in premium screen mesh might initially seem daunting, but the return on investment through enhanced durability, reduced maintenance, and improved efficiency can far outweigh the upfront costs. This economic prudence is a cornerstone of strategic thinking in mining operations today. In conclusion, the world of mining screen mesh is complex and requires a deep understanding of both the product and the operational environment. From material selection to customization, from engaging reputable suppliers to integrating cutting-edge technology, every step must be orchestrated with precision and care. By aligning these aspects with the values of Experience, Expertise, Authoritativeness, and Trustworthiness, mining operations not only ensure they are equipped with the optimal tool but also position themselves for sustainable success in an industry that demands no less.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

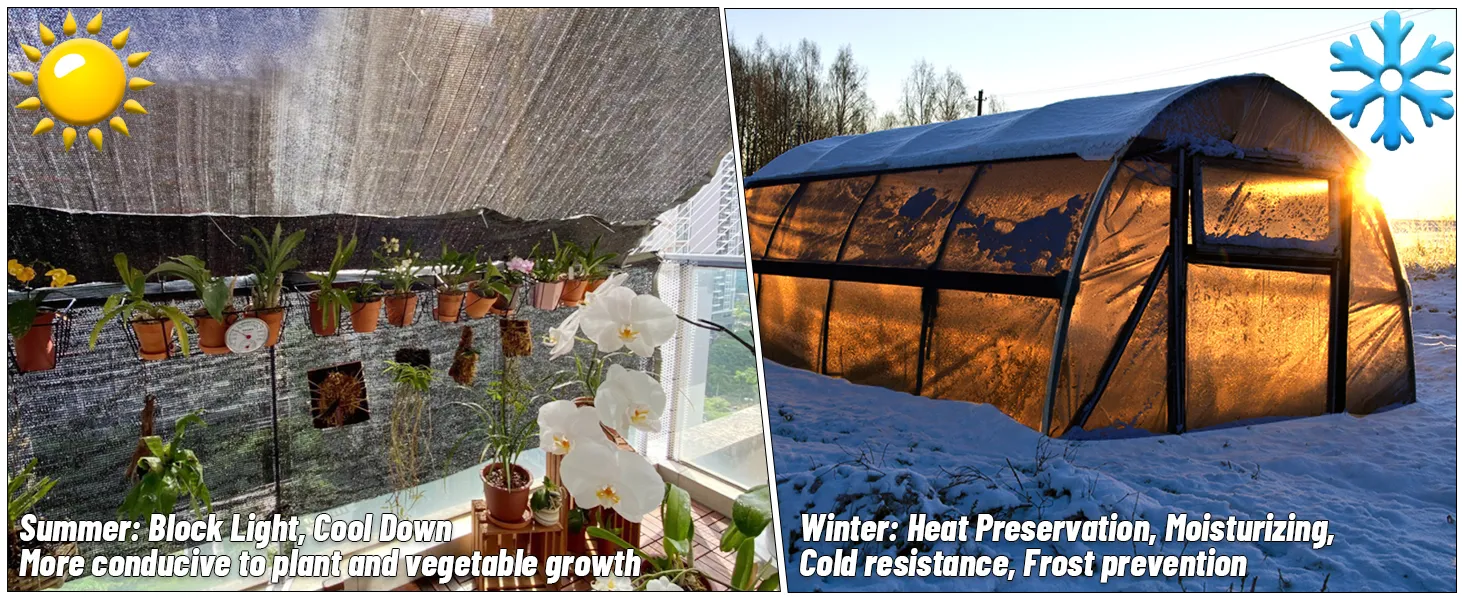

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024