2 月 . 02, 2025 03:43

Back to list

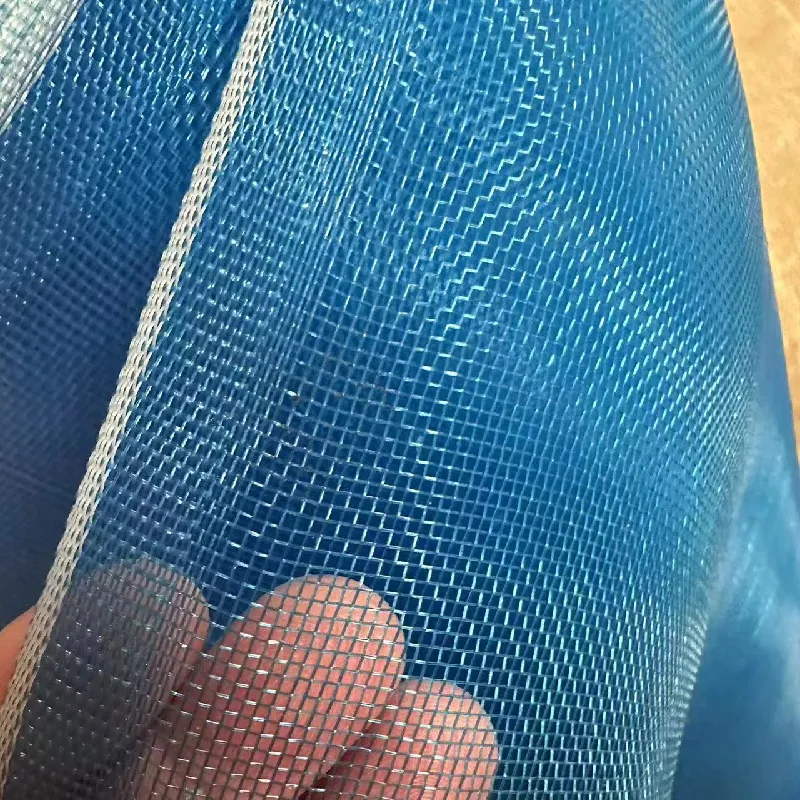

solar bird mesh

Metal steel mesh has become an indispensable component in various sectors, owing to its versatility and robust nature. Its applications range from industrial uses, where it serves as a critical barrier in construction projects, to artistic displays that grace modern architecture with their intricate designs. The adaptability of metal steel mesh, coupled with its durability, makes it a highly sought-after product across different industries.

In the industrial sector, especially in manufacturing and security, metal steel mesh plays a critical role. For industrial filtration, the mesh is ideal due to its ability to filter out impurities without degrading. In security, its application extends to perimeter fencing and protective grilles, where its strength acts as a deterrent against intrusions. The reliability of metal steel mesh in these applications speaks volumes about its authoritative status as a material of choice. Customer experiences with metal steel mesh range from overwhelmingly positive to indispensable, frequently highlighting the adaptability and longevity as its core strengths. Professionals using this material have consistently documented its value in enhancing their operations, whether by amplifying safety, boosting aesthetic appeal, or providing reliable reinforcement. Moreover, as a product backed by years of developmental research and usage, metal steel mesh is a material whose credibility is rooted in its proven performance across different applications. Its established reputation in technical utility and design innovation has made it a trustworthy material that professionals continue to rely on. Experts in metallurgy and construction agree that the future of metal steel mesh holds exciting possibilities, with advancements likely increasing its precision applications and sustainability. As industries evolve, the adaptability and robustness of metal steel mesh ensure that it will remain not just relevant but integral to progressive construction methods and designs. This wealth of attributes confirms that metal steel mesh is not merely another material on the market but an indispensable resource backed by expertise, trusted for its remarkable balance of form and function.

In the industrial sector, especially in manufacturing and security, metal steel mesh plays a critical role. For industrial filtration, the mesh is ideal due to its ability to filter out impurities without degrading. In security, its application extends to perimeter fencing and protective grilles, where its strength acts as a deterrent against intrusions. The reliability of metal steel mesh in these applications speaks volumes about its authoritative status as a material of choice. Customer experiences with metal steel mesh range from overwhelmingly positive to indispensable, frequently highlighting the adaptability and longevity as its core strengths. Professionals using this material have consistently documented its value in enhancing their operations, whether by amplifying safety, boosting aesthetic appeal, or providing reliable reinforcement. Moreover, as a product backed by years of developmental research and usage, metal steel mesh is a material whose credibility is rooted in its proven performance across different applications. Its established reputation in technical utility and design innovation has made it a trustworthy material that professionals continue to rely on. Experts in metallurgy and construction agree that the future of metal steel mesh holds exciting possibilities, with advancements likely increasing its precision applications and sustainability. As industries evolve, the adaptability and robustness of metal steel mesh ensure that it will remain not just relevant but integral to progressive construction methods and designs. This wealth of attributes confirms that metal steel mesh is not merely another material on the market but an indispensable resource backed by expertise, trusted for its remarkable balance of form and function.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024