2 月 . 02, 2025 02:29

Back to list

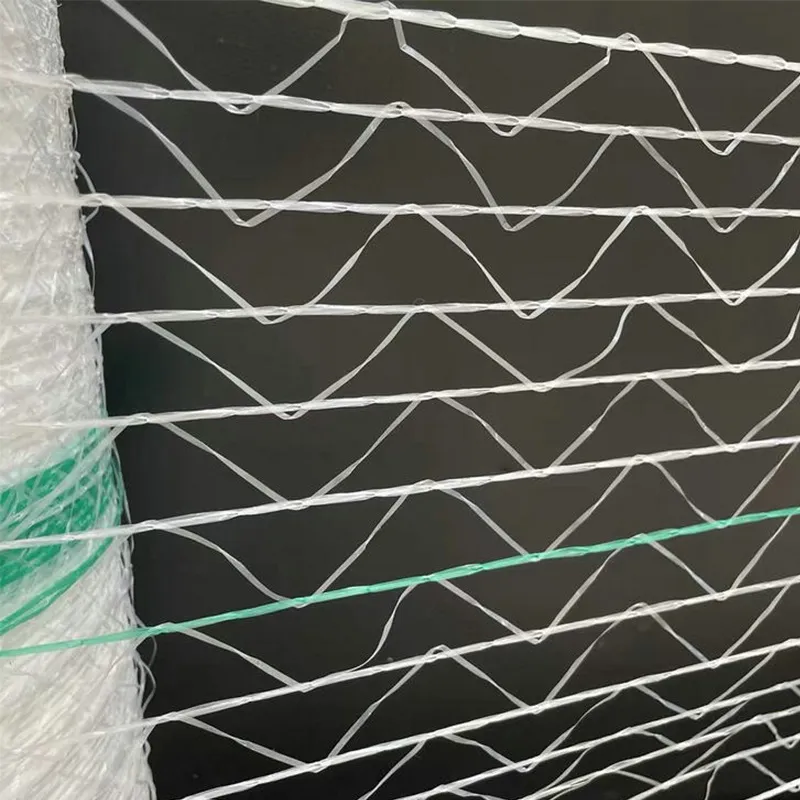

solar bird mesh

The digital world thrives on innovation, and the manufacturing sector is no exception. Mesh manufacturing machines represent a significant leap forward in fabricating intricate structures across various industries, offering notable advancements in productivity and quality. With new technologies revolutionizing traditional manufacturing methods, understanding mesh manufacturing machines' capabilities is crucial for businesses aiming to remain competitive in today's fast-paced market.

Trustworthiness in mesh manufacturing machines can largely be attributed to the robust testing and quality control processes established by manufacturers. Reputable machine producers undergo comprehensive testing procedures to guarantee that each piece of equipment performs to specification. By leveraging certifications and adhering to international quality standards such as ISO 9001, manufacturers ensure that their products offer consistency and reliability. Reassurance is provided to end-users through detailed documentation and transparent communication, both of which are key factors in building long-term trust. For businesses seeking to invest in mesh manufacturing machines, it is crucial to consider the machine's compatibility with existing systems and its ability to support future expansion. Engaging with trusted suppliers who offer comprehensive support, training, and maintenance services can make all the difference in achieving a successful integration. Aligning with suppliers who demonstrate industry recognition and a proven track record of innovation will help mitigate potential risks associated with adopting new technologies. In an era where customization and efficiency are paramount, mesh manufacturing machines stand out as indispensable tools for modern manufacturers. They not only enhance precision and versatility but also align with sustainable manufacturing practices by minimizing waste and energy consumption. Embracing this technology can empower businesses to deliver superior products and foster a competitive edge in increasingly challenging markets. To conclude, the strategic implementation of mesh manufacturing machines requires a comprehensive approach that encompasses practical experience, technical expertise, authoritative validation, and a clear understanding of the technology's long-term benefits. By focusing on these key indicators, businesses can leverage mesh manufacturing machines to drive innovation and achieve unparalleled success in their respective fields.

Trustworthiness in mesh manufacturing machines can largely be attributed to the robust testing and quality control processes established by manufacturers. Reputable machine producers undergo comprehensive testing procedures to guarantee that each piece of equipment performs to specification. By leveraging certifications and adhering to international quality standards such as ISO 9001, manufacturers ensure that their products offer consistency and reliability. Reassurance is provided to end-users through detailed documentation and transparent communication, both of which are key factors in building long-term trust. For businesses seeking to invest in mesh manufacturing machines, it is crucial to consider the machine's compatibility with existing systems and its ability to support future expansion. Engaging with trusted suppliers who offer comprehensive support, training, and maintenance services can make all the difference in achieving a successful integration. Aligning with suppliers who demonstrate industry recognition and a proven track record of innovation will help mitigate potential risks associated with adopting new technologies. In an era where customization and efficiency are paramount, mesh manufacturing machines stand out as indispensable tools for modern manufacturers. They not only enhance precision and versatility but also align with sustainable manufacturing practices by minimizing waste and energy consumption. Embracing this technology can empower businesses to deliver superior products and foster a competitive edge in increasingly challenging markets. To conclude, the strategic implementation of mesh manufacturing machines requires a comprehensive approach that encompasses practical experience, technical expertise, authoritative validation, and a clear understanding of the technology's long-term benefits. By focusing on these key indicators, businesses can leverage mesh manufacturing machines to drive innovation and achieve unparalleled success in their respective fields.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024