2 月 . 20, 2025 02:47

Back to list

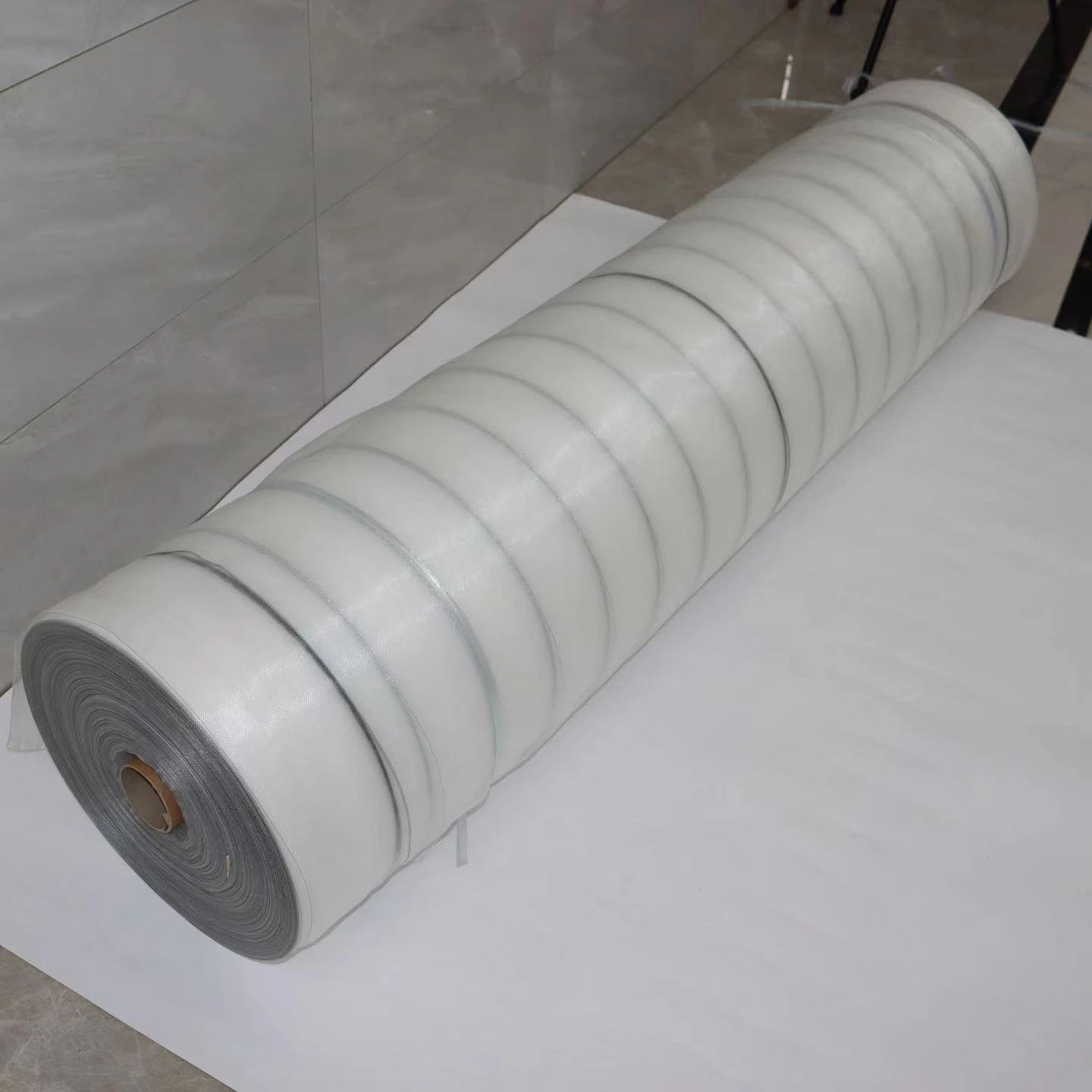

industrial mesh screen

Industrial mesh screens play a pivotal role in various applications, ranging from separation processes to architectural designs. With their versatility and durable nature, these screens are essential components in industries that demand precise filtration and controlled processing environments. Let's delve into the critical aspects that make industrial mesh screens an invaluable asset and analyze their multifaceted benefits.

Trustworthiness in industrial applications is paramount, and manufacturers must adhere to strict industry standards and quality controls. Reliable companies ensure that their industrial mesh screens are rigorously tested for durability and performance before distribution. Understanding the importance of trust in this context, leading manufacturers often provide certifications and transparency regarding their production processes. This commitment not only sustains the reputation of manufacturers but also assures clients of the product's reliability. Expertise in the manufacturing process further contributes to the industrial mesh screen's overall performance. Experienced engineers and technicians employ cutting-edge technology to design screens that meet specific industrial requirements. This expertise ensures that the products not only meet but often exceed industry standards. Manufacturers with decades of experience often leverage their knowledge to innovate and adapt mesh screens to new industrial challenges, maintaining their competitive edge in the market. The real-world experience of industries that have integrated industrial mesh screens into their operations highlights their transformative impact. In wastewater management, for instance, the use of finely-tuned mesh screens has significantly reduced impurities, leading to cleaner water output. Similarly, in the food and beverage industry, mesh screens help maintain product quality and safety by efficiently filtering contaminants. In conclusion, industrial mesh screens are indispensable in today's technologically advanced industries. Their precise filtration capabilities, robust construction, and adaptable design make them suitable for a wide range of applications. By choosing a reputable manufacturer, businesses can ensure that they are investing in products that offer reliable performance, thereby enhancing operational efficiency and contributing to sustainable industrial practices. As industries continue to evolve, the role of industrial mesh screens will undoubtedly expand, solidifying their place as critical components in future innovations.

Trustworthiness in industrial applications is paramount, and manufacturers must adhere to strict industry standards and quality controls. Reliable companies ensure that their industrial mesh screens are rigorously tested for durability and performance before distribution. Understanding the importance of trust in this context, leading manufacturers often provide certifications and transparency regarding their production processes. This commitment not only sustains the reputation of manufacturers but also assures clients of the product's reliability. Expertise in the manufacturing process further contributes to the industrial mesh screen's overall performance. Experienced engineers and technicians employ cutting-edge technology to design screens that meet specific industrial requirements. This expertise ensures that the products not only meet but often exceed industry standards. Manufacturers with decades of experience often leverage their knowledge to innovate and adapt mesh screens to new industrial challenges, maintaining their competitive edge in the market. The real-world experience of industries that have integrated industrial mesh screens into their operations highlights their transformative impact. In wastewater management, for instance, the use of finely-tuned mesh screens has significantly reduced impurities, leading to cleaner water output. Similarly, in the food and beverage industry, mesh screens help maintain product quality and safety by efficiently filtering contaminants. In conclusion, industrial mesh screens are indispensable in today's technologically advanced industries. Their precise filtration capabilities, robust construction, and adaptable design make them suitable for a wide range of applications. By choosing a reputable manufacturer, businesses can ensure that they are investing in products that offer reliable performance, thereby enhancing operational efficiency and contributing to sustainable industrial practices. As industries continue to evolve, the role of industrial mesh screens will undoubtedly expand, solidifying their place as critical components in future innovations.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024