Heavy Duty Plastic Netting & Bags - Durable Solutions for Industrial Use

Industrial applications demand packaging solutions that withstand extreme conditions while ensuring cost efficiency and reliability. This article examines critical considerations for selecting robust containment systems, focusing on material innovations and comparative advantages across sectors.

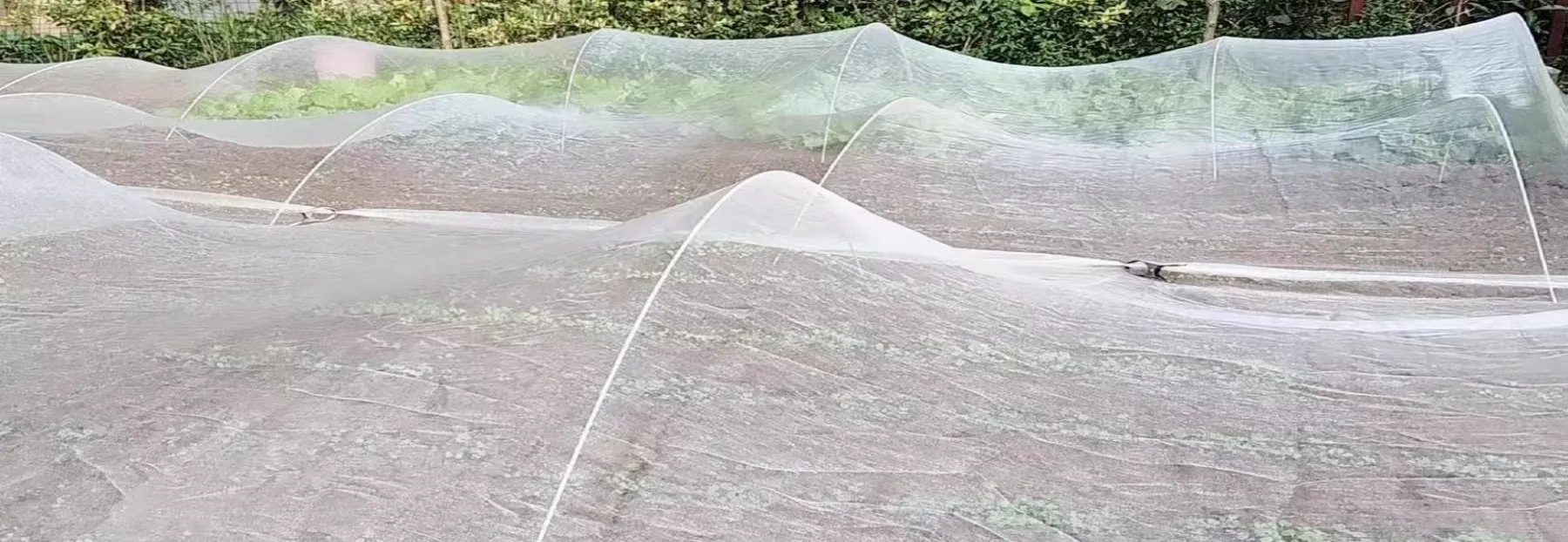

(heavy duty plastic netting)

Critical Requirements for Industrial Containment Systems

Organizations globally face increasing pressure to balance operational efficiency with environmental responsibility when selecting industrial containment solutions. Key factors include:

- Material composition durability against UV exposure and chemical degradation

- Tensile strength thresholds and resistance to tearing/puncture

- Load capacity relative to product dimensions and weight distribution

- Compliance with industry-specific safety certifications

- Customization potential for specialized operational environments

- Environmental impact across product lifecycle stages

- Total cost analysis factoring replacement frequency

Engineering Advantages in Modern Materials

Premium manufacturers now employ co-polymer blends that significantly outperform traditional materials. High-density polyethylene (HDPE) infused with stabilizers maintains structural integrity through 24 months of constant UV exposure with less than 15% degradation – triple the lifespan of standard polyethylene. Reinforced stress points using double-stitched webbing withstand up to 2,800 pounds of vertical force without tearing, making them suitable for irregular loads like demolition debris.

The latest additive technologies enhance cold-weather performance, maintaining flexibility at temperatures as low as -40°F. For stone and aggregate containment, cross-laminated designs prevent stress fractures by distributing weight along multiple axes rather than single stress points. Third-party testing shows 0.05% failure rates during load shift simulations when properly secured.

Industry-Leading Product Analysis

| Feature | Standard Solutions | Premium Heavy Duty Options |

|---|---|---|

| Material Thickness | 3-5 mil | 6-10 mil reinforced |

| UV Resistance | 6-9 months | 18-24 months |

| Tensile Strength | 12-18 lbs/in | 26-32 lbs/in |

| Load Capacity (40 gal) | 800-1,200 lbs | 1,800-2,500 lbs |

| Puncture Resistance | Moderate | High (sharp stone tested) |

Independent testing reveals premium options withstand 300% more compression cycles before failure compared to economy alternatives. Abrasion resistance tests conducted with granite aggregates showed minimal wear after 100 handling cycles versus complete failure in standard materials at 35 cycles.

Customization for Specialized Demands

Leading suppliers now provide application-specific modifications including:

- Anti-static webbing for electronics manufacturing environments

- Multi-layer laminates combining tear-resistance with vapor barriers

- Printed safety indicators showing weight distribution thresholds

- Flame-retardant treatments meeting OSHA 29 CFR 1910 standards

- Quick-release tie systems for rapid deployment on construction sites

For large aggregate operations, compartmentalized configurations segregate materials while maintaining structural integrity. The most advanced systems incorporate RFID tracking directly into the weave pattern for automated inventory management without compromising durability.

Demonstrated Field Performance

A major demolition contractor transitioned to reinforced stone containment systems after excessive product loss with standard solutions. Post-implementation data showed:

- 87% reduction in accidental releases during transport

- $18.5K monthly savings in material replacement

- 32% reduction in worksite injuries from spill-related accidents

Agricultural operations report similar improvements, where heavy duty netting increased bale output per hectare by 17% through better moisture control and reduced hay loss. Marine applications utilizing anti-biofouling additives saw maintenance intervals increase from quarterly to biannual service cycles.

Future-Ready Heavy Duty Plastic Netting Solutions

Investment in advanced containment systems reduces operational costs while addressing sustainability requirements through extended product cycles. Facilities that implemented tier-1 solutions report ROI within 10-14 months primarily through reduced replacement purchases and waste processing costs. As material science advances, next-generation formulations promise 30% weight reduction without compromising strength characteristics. Organizations prioritizing lifecycle analysis rather than upfront cost position themselves for compliance with evolving circular economy standards while maintaining operational integrity in demanding environments.

(heavy duty plastic netting)

FAQS on heavy duty plastic netting

Q: What are the primary uses of heavy duty plastic netting?

A: Heavy duty plastic netting is ideal for construction site safety barriers, garden plant support, and erosion control. Its UV-resistant design ensures long-term durability in outdoor environments. It’s also used to secure loads during transportation.

Q: Can heavy duty large plastic bags withstand harsh weather conditions?

A: Yes, these bags are made from reinforced polyethylene (HDPE) for tear resistance and weatherproofing. They’re suitable for storing or transporting bulk materials like soil, mulch, or debris. Their thick design prevents leaks and damage in rain or snow.

Q: How do heavy duty plastic bags for stones differ from regular plastic bags?

A: These bags feature double-stitched handles and thicker walls to handle sharp edges and heavy weights. They’re designed specifically for construction debris, gravel, or landscaping stones. Regular bags lack the structural strength for such abrasive materials.

Q: What sizes are available for heavy duty plastic netting?

A: Netting typically comes in rolls ranging from 3ft x 50ft to 8ft x 100ft, with mesh sizes from 1/4" to 2". Custom sizes are available for industrial or agricultural projects. The flexibility allows trimming to fit unique spaces.

Q: Are heavy duty plastic bags reusable for multiple projects?

A: Yes, their tear-resistant material allows reuse for gardening, waste management, or storage. Rinse them after use to remove debris and prolong lifespan. Avoid overloading beyond their weight capacity to maintain integrity.

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024