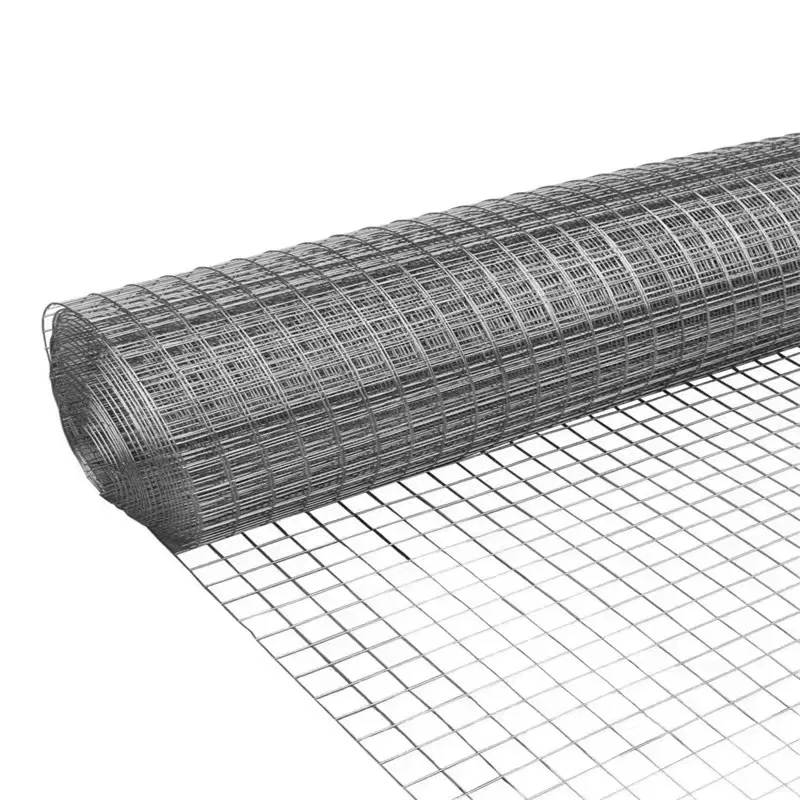

galvanized steel net

The Versatility and Advantages of Galvanized Steel Nets

Galvanized steel nets have emerged as a crucial component in various industries due to their unique properties and versatility. These nets, made from steel that has undergone a galvanization process, combine strength with corrosion resistance, making them ideal for a wide range of applications. From construction to agriculture, the usage of galvanized steel nets has proven to be beneficial in enhancing efficiency and durability.

Understanding Galvanization

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rust and corrosion. This is typically achieved through either hot-dip galvanization or electro-galvanization. In the hot-dip process, steel is submerged in molten zinc, creating a robust coating that can withstand harsh environmental conditions. On the other hand, electro-galvanization involves applying a zinc layer through an electrochemical process, which results in a thinner coating but can provide a smooth finish suitable for certain applications. Regardless of the method, both processes significantly increase the lifespan of the steel, making it an ideal choice for netting.

Applications in Construction

In the construction industry, galvanized steel nets serve multiple functions. They are often used as reinforcement in concrete, providing additional strength and stability. The corrosion resistance of galvanized steel ensures that these nets will endure the test of time, even in concrete structures exposed to moisture and other elements.

Furthermore, galvanized steel nets are also utilized in road construction and maintenance. They can be employed as safety barriers and fencing to protect construction sites and ensure public safety. The visibility and strength of galvanized steel nets make them a favorite choice for temporary fencing solutions. Their lightweight nature allows for easy transport and installation, which is essential in fast-paced construction environments.

Agricultural Uses

galvanized steel net

The agricultural sector has also benefited significantly from the use of galvanized steel nets. These nets are commonly used in fencing for livestock and crop protection. The durability of galvanized steel means that these fences can withstand extreme weather conditions, animal impacts, and other environmental factors without succumbing to rust or wear and tear.

In addition to fencing, galvanized steel nets are essential for supporting structures in gardening and horticulture, such as trellises for climbing plants. Their flexibility allows them to be shaped into various formations, making them suitable for different plant growth requirements. Moreover, the nets can also be used for soil erosion control, helping to stabilize soil on slopes and prevent the loss of vital nutrients.

Environmental Considerations

One of the significant advantages of galvanized steel nets is their environmental impact. Steel is a recyclable material, meaning that at the end of its life cycle, galvanized steel nets can be reprocessed and repurposed. This not only reduces waste but also lowers the demand for new raw materials. By choosing galvanized steel, industries are making a sustainable choice that contributes to a circular economy.

Conclusion

The prominence of galvanized steel nets in various sectors demonstrates their versatility and practicality. Their inherent strength, coupled with corrosion resistance, makes them an ideal choice for construction and agricultural applications. The long lifespan and environmental benefits of galvanized steel further bolster its appeal.

As industries continue to seek durable and efficient solutions, the demand for galvanized steel nets is expected to grow. Whether providing structural support in high-rise buildings, safeguarding agricultural fields, or serving as protective barriers in construction sites, galvanized steel nets are poised to play a pivotal role in enhancing productivity and sustainability across various domains. Their seamless integration into everyday applications illustrates the lasting impact of innovative processes like galvanization in modern industry.

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024