2 月 . 10, 2025 11:46

Back to list

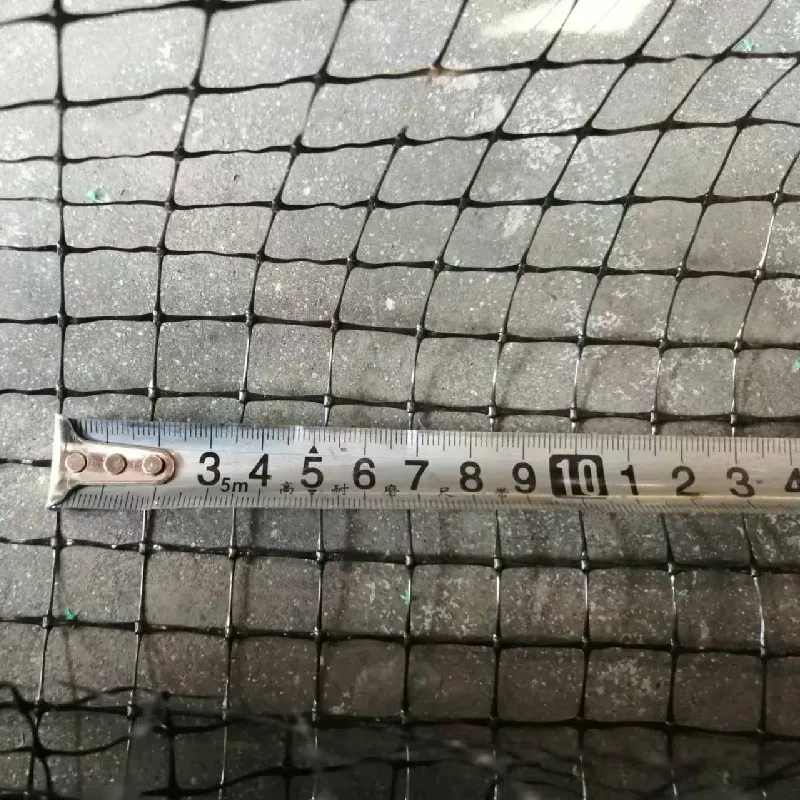

nylon filter cloth mesh

When selecting the right material for fencing projects or other structural needs, galvanized hardware cloth often emerges as a top contender. Its blend of durability, cost-effectiveness, and versatility makes it an invaluable resource for both professionals and DIY enthusiasts. Here, we dive deep into understanding what makes galvanized hardware cloth stand out, backed by real-world applications and expert insights.

The trustworthiness of galvanized hardware cloth is rooted in decades of use across various sectors. For instance, in the poultry industry, it is commonly used to construct cages and aviaries, ensuring safety while providing a clear view for monitoring the animals. Veterinarians and animal care experts often recommend it as it minimizes injury risks due to its smooth, yet sturdy construction. Feedback from those who have extensive experience with galvanized hardware cloth highlights its ease of installation. Even those new to DIY projects find it manageable to work with, often requiring only basic tools for cutting and shaping. Its adaptability is evident in its use across projects of different scales and scopes, from simple home repairs to complex architectural undertakings. Moreover, from an economic perspective, galvanized hardware cloth offers excellent value for money. Its durability reduces the need for frequent replacements, translating to long-term savings. Additionally, its availability in various gauges and sizes meets the demands of different project requirements, ensuring that users pay for precisely what they need without unnecessary overspending. Ultimately, the expertise, authoritativeness, and trustworthiness surrounding galvanized hardware cloth are reinforced by its wide-ranging applications and the expert endorsements it receives. As an industry staple, its performance and reliability are well-documented, making it a go-to solution for those seeking a resilient, versatile, and economical material for their construction or crafting needs. By prioritizing quality and longevity, users ensure that their projects stand the test of time, backed by the proven track record of galvanized hardware cloth.

The trustworthiness of galvanized hardware cloth is rooted in decades of use across various sectors. For instance, in the poultry industry, it is commonly used to construct cages and aviaries, ensuring safety while providing a clear view for monitoring the animals. Veterinarians and animal care experts often recommend it as it minimizes injury risks due to its smooth, yet sturdy construction. Feedback from those who have extensive experience with galvanized hardware cloth highlights its ease of installation. Even those new to DIY projects find it manageable to work with, often requiring only basic tools for cutting and shaping. Its adaptability is evident in its use across projects of different scales and scopes, from simple home repairs to complex architectural undertakings. Moreover, from an economic perspective, galvanized hardware cloth offers excellent value for money. Its durability reduces the need for frequent replacements, translating to long-term savings. Additionally, its availability in various gauges and sizes meets the demands of different project requirements, ensuring that users pay for precisely what they need without unnecessary overspending. Ultimately, the expertise, authoritativeness, and trustworthiness surrounding galvanized hardware cloth are reinforced by its wide-ranging applications and the expert endorsements it receives. As an industry staple, its performance and reliability are well-documented, making it a go-to solution for those seeking a resilient, versatile, and economical material for their construction or crafting needs. By prioritizing quality and longevity, users ensure that their projects stand the test of time, backed by the proven track record of galvanized hardware cloth.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024