3 月 . 07, 2025 05:32

Back to list

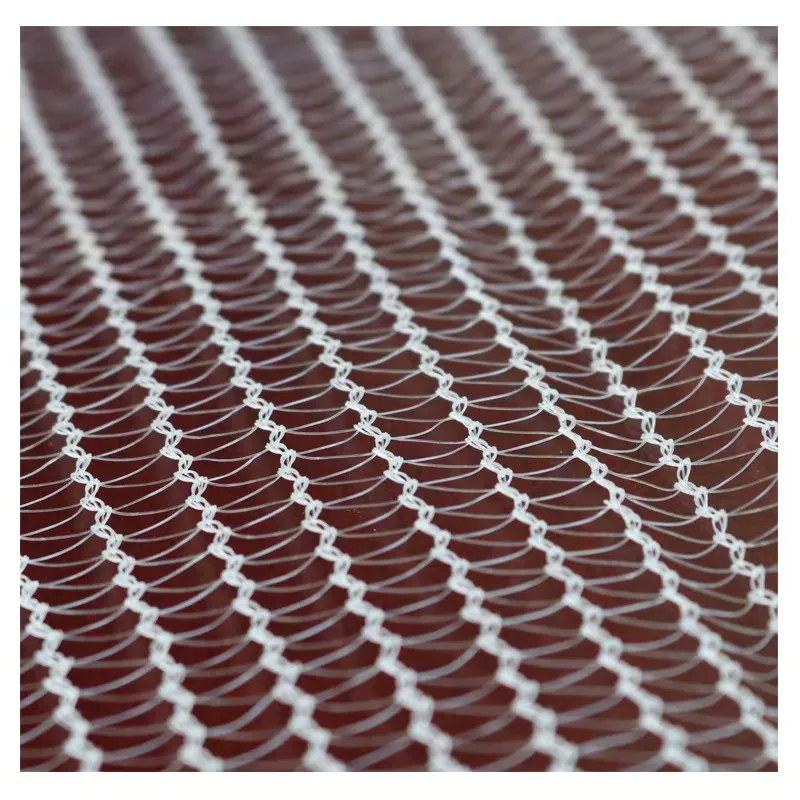

Thickened Nylon Mesh

In the dynamic world of industrial applications, fine screen mesh made from stainless steel stands out as a critical component for many processes, valued for its durability, adaptability, and high performance. As industries continue to evolve, the demand for high-quality materials that offer precision and reliability increases. Here's an earthshaking revelation of what fine screen mesh stainless steel brings to the table and why it remains unparalleled in its domain.

Authoritativeness extends beyond product quality into the realm of thought leadership. Companies at the forefront of stainless steel screen mesh technology often engage in research and development, continually pushing the boundaries of what these materials can achieve. By publishing findings, presenting at industry conferences, and collaborating with academic institutions, these companies solidify their position as leaders. Such efforts not only foster innovation but also assure clients that the solutions offered are at the cutting edge of technological advancement. Trustworthiness in this arena is built on transparency and a track record of success. Firms offer detailed specifications and certifications, such as ISO compliance, to assure customers of the product's quality. Customer service plays a vital role further by providing expert guidance, from initial consultation to after-sales support. This holistic approach builds a relationship of trust between the manufacturer and the client, laying the groundwork for continuous partnerships. In practice, stainless steel fine screen mesh finds diverse applications across industries. In water treatment plants, its ability to perform under constant exposure to moisture without degrading is invaluable. Chemical processing plants appreciate its non-reactive nature, maintaining purity and safety standards. In the food and beverage industry, the mesh offers a balance of hygiene and precision, crucial for filtration and sieving tasks. The mesh's versatility is not merely about function; it's about adapting to each industry's unique demands with precision and reliability. In conclusion, fine screen mesh stainless steel is a linchpin in modern industrial processes, offering unmatched durability and precision. Companies investing in its development are not just selling a product; they are providing a solution built on expertise, authority, and trust. As advancements continue, those at the helm of this technology remain committed to breaking new ground, ensuring that industries worldwide can rely on stainless steel meshes that define quality and efficiency. These products are not just components; they are critical infrastructures that empower industries to soar to new heights.

Authoritativeness extends beyond product quality into the realm of thought leadership. Companies at the forefront of stainless steel screen mesh technology often engage in research and development, continually pushing the boundaries of what these materials can achieve. By publishing findings, presenting at industry conferences, and collaborating with academic institutions, these companies solidify their position as leaders. Such efforts not only foster innovation but also assure clients that the solutions offered are at the cutting edge of technological advancement. Trustworthiness in this arena is built on transparency and a track record of success. Firms offer detailed specifications and certifications, such as ISO compliance, to assure customers of the product's quality. Customer service plays a vital role further by providing expert guidance, from initial consultation to after-sales support. This holistic approach builds a relationship of trust between the manufacturer and the client, laying the groundwork for continuous partnerships. In practice, stainless steel fine screen mesh finds diverse applications across industries. In water treatment plants, its ability to perform under constant exposure to moisture without degrading is invaluable. Chemical processing plants appreciate its non-reactive nature, maintaining purity and safety standards. In the food and beverage industry, the mesh offers a balance of hygiene and precision, crucial for filtration and sieving tasks. The mesh's versatility is not merely about function; it's about adapting to each industry's unique demands with precision and reliability. In conclusion, fine screen mesh stainless steel is a linchpin in modern industrial processes, offering unmatched durability and precision. Companies investing in its development are not just selling a product; they are providing a solution built on expertise, authority, and trust. As advancements continue, those at the helm of this technology remain committed to breaking new ground, ensuring that industries worldwide can rely on stainless steel meshes that define quality and efficiency. These products are not just components; they are critical infrastructures that empower industries to soar to new heights.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024