2 月 . 06, 2025 02:16

Back to list

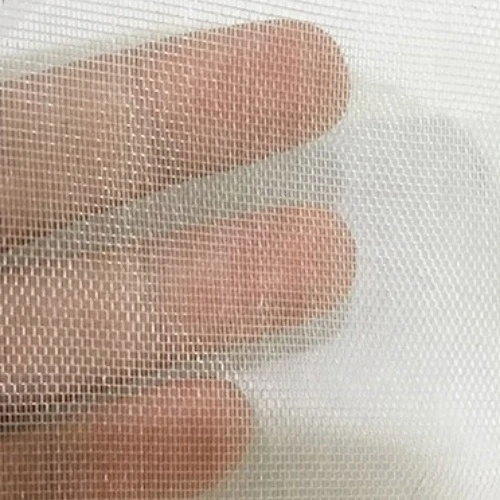

filter steel

The demand for high-quality steel products has grown exponentially as industries continuously seek materials that offer superior durability and performance. Among the myriad of steel products, filter steel has emerged as a unique, innovative solution, leveraged extensively in various industrial applications. This article explores the capabilities of filter steel, underpinning its effectiveness, and how businesses can benefit from its application, while also delving into the qualities that make it stand out in today's competitive landscape.

Authoritative research underscores the superiority of filter steel in various applications. Recent studies highlight its efficiency in capturing finer particles that other materials may fail to filter. The structured matrix of filter steel provides a larger surface area for capturing contaminants, leading to higher filtration efficiency. Moreover, advancements in manufacturing techniques have enabled customization of pore sizes to cater to specific needs, further solidifying its authority in filtration technology. Industry experts advocate for the increased adoption of filter steel, citing its alignment with sustainability goals. Its durability and resistance to chemical reactions reduce the need for replacements and the associated environmental impact of manufacturing and disposing of less durable materials. This aligns with the growing corporate responsibility towards eco-friendly practices, making filter steel an attractive option for industries striving to enhance their sustainability profiles. Trust in filter steel is driven by consistent performance and the reassurance provided by rigorous quality controls during production. Leading manufacturers ensure that each batch of filter steel meets regulatory standards and is subject to comprehensive testing protocols. This assurance of quality builds confidence among consumers and end-users, fostering a perception of reliability that is invaluable in crucial industrial operations where failure is not an option. In conclusion, the application of filter steel is not just beneficial but vital across several industries where filtration reliability and precision are non-negotiable. Its proven track record of performance, coupled with expert endorsements and a commitment to quality, positions filter steel as a forerunner in filtration solutions. As industries continue to evolve, the continued innovation and application of filter steel will undoubtedly contribute to greater efficiency, sustainability, and operational excellence. Businesses looking to optimize their processes should consider integrating filter steel to reap its myriad benefits, advancing both their product capabilities and market competitiveness.

Authoritative research underscores the superiority of filter steel in various applications. Recent studies highlight its efficiency in capturing finer particles that other materials may fail to filter. The structured matrix of filter steel provides a larger surface area for capturing contaminants, leading to higher filtration efficiency. Moreover, advancements in manufacturing techniques have enabled customization of pore sizes to cater to specific needs, further solidifying its authority in filtration technology. Industry experts advocate for the increased adoption of filter steel, citing its alignment with sustainability goals. Its durability and resistance to chemical reactions reduce the need for replacements and the associated environmental impact of manufacturing and disposing of less durable materials. This aligns with the growing corporate responsibility towards eco-friendly practices, making filter steel an attractive option for industries striving to enhance their sustainability profiles. Trust in filter steel is driven by consistent performance and the reassurance provided by rigorous quality controls during production. Leading manufacturers ensure that each batch of filter steel meets regulatory standards and is subject to comprehensive testing protocols. This assurance of quality builds confidence among consumers and end-users, fostering a perception of reliability that is invaluable in crucial industrial operations where failure is not an option. In conclusion, the application of filter steel is not just beneficial but vital across several industries where filtration reliability and precision are non-negotiable. Its proven track record of performance, coupled with expert endorsements and a commitment to quality, positions filter steel as a forerunner in filtration solutions. As industries continue to evolve, the continued innovation and application of filter steel will undoubtedly contribute to greater efficiency, sustainability, and operational excellence. Businesses looking to optimize their processes should consider integrating filter steel to reap its myriad benefits, advancing both their product capabilities and market competitiveness.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024