2 月 . 15, 2025 00:59

Back to list

fibc jumbo bag

FIBC jumbo bags, commonly referred to as bulk bags, have emerged as indispensable tools across various industries. Offering unmatched versatility, these bags are revered for their capacity to handle, store, and transport large quantities of goods. Let's delve into why these bags are not just a choice but a necessity for many businesses, focusing on experience, expertise, authoritativeness, and trustworthiness.

Trustworthiness encompasses the environmental impact and sustainability of these bags. FIBC jumbo bags are, by design, reusable and recyclable, aligning with contemporary sustainability goals. After the initial use, they can be repurposed for various applications, minimizing waste. Moreover, leading manufacturers have initiated programs for refurbishing or recycling these bags, underlining their commitment to environmental responsibility. Such initiatives resonate well with businesses aiming to reduce their carbon footprint. Furthermore, the trust placed in FIBC jumbo bags is highlighted through numerous case studies where industries like agriculture, construction, and chemicals have adopted these bags for enhanced productivity. In agriculture, for instance, these bags have simplified the transport of crops, protecting them from spoilage and contamination. In construction, the ability to transport sand, gravel, and cement seamlessly has proven invaluable, especially in projects with complex logistics. These real-world applications validate the necessity and reliability of jumbo bags. To conclude, the adoption of FIBC jumbo bags is a testament to their effectiveness and adaptability. As industries continue to evolve, the demand for efficient, safe, and sustainable packaging solutions will only increase, and FIBC jumbo bags are poised to meet these demands. Their widespread use across diverse sectors underscores their integral role in modern supply chains, making them a product backed by experience, expertise, authority, and trust.

Trustworthiness encompasses the environmental impact and sustainability of these bags. FIBC jumbo bags are, by design, reusable and recyclable, aligning with contemporary sustainability goals. After the initial use, they can be repurposed for various applications, minimizing waste. Moreover, leading manufacturers have initiated programs for refurbishing or recycling these bags, underlining their commitment to environmental responsibility. Such initiatives resonate well with businesses aiming to reduce their carbon footprint. Furthermore, the trust placed in FIBC jumbo bags is highlighted through numerous case studies where industries like agriculture, construction, and chemicals have adopted these bags for enhanced productivity. In agriculture, for instance, these bags have simplified the transport of crops, protecting them from spoilage and contamination. In construction, the ability to transport sand, gravel, and cement seamlessly has proven invaluable, especially in projects with complex logistics. These real-world applications validate the necessity and reliability of jumbo bags. To conclude, the adoption of FIBC jumbo bags is a testament to their effectiveness and adaptability. As industries continue to evolve, the demand for efficient, safe, and sustainable packaging solutions will only increase, and FIBC jumbo bags are poised to meet these demands. Their widespread use across diverse sectors underscores their integral role in modern supply chains, making them a product backed by experience, expertise, authority, and trust.

Next:

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

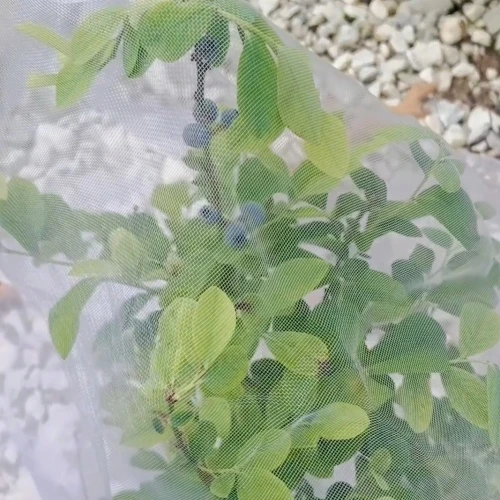

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024