fibc big bag

Understanding FIBC Big Bags A Versatile Solution for Bulk Packaging

In today's world of logistics and supply chain management, efficiency and sustainability have become paramount. One solution that is gaining traction in various industries is the Flexible Intermediate Bulk Container (FIBC), commonly known as big bags. These versatile bags have revolutionized the way bulk materials are stored and transported, offering numerous benefits over traditional packaging methods.

What is an FIBC Big Bag?

FIBC big bags are large, industrial-grade sacks made from woven polypropylene fabric. They are designed to hold a substantial amount of bulk materials, often ranging from 500 to 2,000 kilograms. The bags can be customized in terms of size, shape, and features, making them suitable for a wide array of applications in industries such as agriculture, construction, chemicals, food products, and more. Their lightweight nature, combined with their ability to carry heavy loads, makes them a popular choice for companies looking to optimize their packaging solutions.

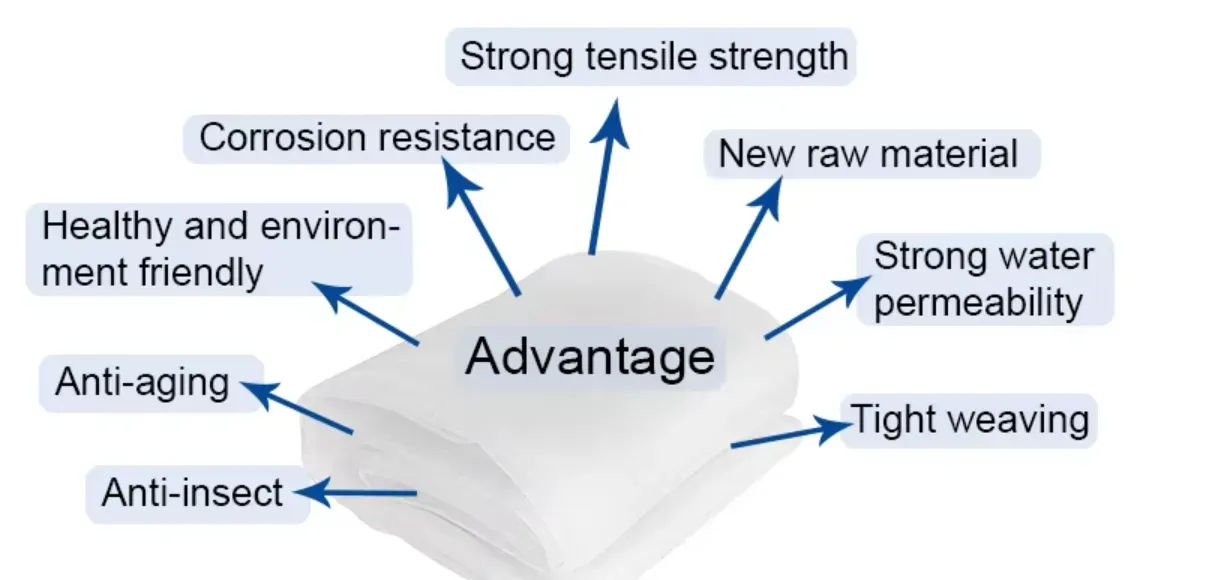

Benefits of FIBC Big Bags

1. Cost-Effectiveness One of the most significant advantages of utilizing FIBC big bags is the cost savings they provide. Compared to traditional packaging options like drums or boxes, big bags require less material and can be produced at a lower cost. Additionally, they can be folded when empty, saving valuable storage space and reducing shipping costs.

2. Durability Made from high-quality, UV-resistant polypropylene, FIBCs are designed to withstand harsh environmental conditions. They are resistant to tears, punctures, and abrasions, ensuring the safe transport of materials without compromising on strength. Properly constructed and maintained big bags can last for multiple trips, adding to their cost-effectiveness.

fibc big bag

3. Versatility FIBC big bags can accommodate a wide variety of materials, from granules and powders to crystals and liquids. They come in various designs, such as standard FIBCs, ventilated bags, and conductive bags, each serving specialized purposes. This versatility makes them an ideal solution for numerous industries, allowing for tailored bulk packaging.

4. Ease of Handling Big bags are designed for easy handling. They typically come with four lifting loops, allowing for straightforward loading and unloading using forklifts or cranes. This ease of use can significantly enhance operational efficiency in warehouses and transportation settings.

5. Environmental Impact As companies increasingly seek to adopt sustainable practices, FIBC big bags offer an eco-friendly alternative to single-use packaging. They are recyclable and can be reused several times, reducing the overall environmental footprint of packaging waste.

Applications of FIBC Big Bags

FIBC big bags are utilized in a broad spectrum of applications. In the construction industry, they are commonly used for transporting sand, gravel, and cement. In agriculture, they are perfect for bulk grains and fertilizers. The food industry also benefits from FIBCs for transporting ingredients like sugar, flour, and rice safely and hygienically. Additionally, the chemical sector uses FIBC bags for handling hazardous materials, ensuring safety and compliance with regulations.

Conclusion

As industries continue to evolve, the demand for efficient and sustainable packaging solutions will grow. FIBC big bags emerge as a practical choice for businesses aiming to streamline their operations while being mindful of environmental concerns. Their robust nature, cost-effectiveness, and versatility make them indispensable in today’s supply chain. Whether for transporting raw materials or storing finished products, FIBC big bags offer an innovative approach to bulk packaging challenges, solidifying their place as a preferred solution in numerous sectors. Embracing this technology can lead to improved logistics, operational efficiency, and sustainability within any organization.

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024