1 月 . 25, 2025 21:38

Back to list

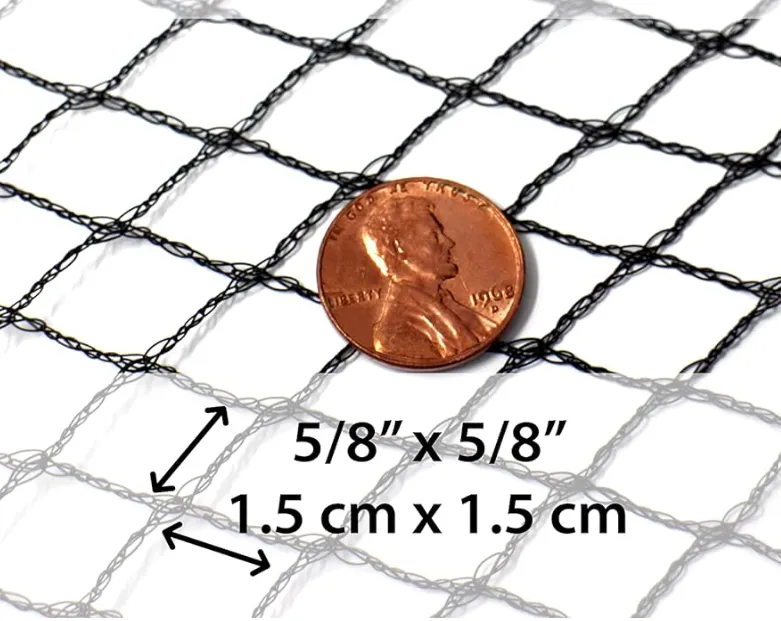

extruded steel mesh

Extruded steel mesh, a crucial component across numerous industries, offers a blend of strength, adaptability, and efficiency that is unmatched by traditional materials. Having spent years exploring its applications and benefits, I've witnessed firsthand how it revolutionizes processes and products alike. This robust material stands as a testament to engineering innovation, combining cutting-edge technology with practical utility, serving as a testament to human ingenuity in addressing complex demands.

Similarly, in the aerospace industry, extruded steel mesh is utilized for its excellent strength-to-weight ratio. As aircraft design increasingly tilts towards performance efficiency and fuel economy, materials like this mesh become invaluable. It supports structural components without adding unnecessary weight, thereby maximizing payloads and minimizing fuel consumption. Its corrosion resistance further benefits the aerospace sector, where exposure to varied atmospheric conditions is a regular occurrence. From an expert standpoint, the precision and adaptability of extruded steel mesh also make it a valuable resource in architecture and art. Architects leverage this material to create intricate designs and facades, taking advantage of its pliability and strength to push creative boundaries without compromising on safety or durability. In art installations, the mesh allows artists to explore large-scale projects, providing a supportive framework that remains aesthetically pleasing. It's essential to underscore the reputation of extruded steel mesh manufacturers, who consistently demonstrate expertise and authority in the industry. These manufacturers ensure rigorous testing and quality control measures are in place to validate the integrity of their products. Customers and industries relying on extruded steel mesh can trust in its performance, assured by the certifications and thorough quality checks conducted throughout the production process. In sum, extruded steel mesh continues to prove itself an indispensable material in crafting the world around us. Combining extensive research, industry experience, and technical expertise, this material not only meets existing needs but also anticipates future demands, ensuring it remains a fundamental element in industrial innovation. It's these qualities that drive its growing popularity and widespread adoption across various pivotal sectors.

Similarly, in the aerospace industry, extruded steel mesh is utilized for its excellent strength-to-weight ratio. As aircraft design increasingly tilts towards performance efficiency and fuel economy, materials like this mesh become invaluable. It supports structural components without adding unnecessary weight, thereby maximizing payloads and minimizing fuel consumption. Its corrosion resistance further benefits the aerospace sector, where exposure to varied atmospheric conditions is a regular occurrence. From an expert standpoint, the precision and adaptability of extruded steel mesh also make it a valuable resource in architecture and art. Architects leverage this material to create intricate designs and facades, taking advantage of its pliability and strength to push creative boundaries without compromising on safety or durability. In art installations, the mesh allows artists to explore large-scale projects, providing a supportive framework that remains aesthetically pleasing. It's essential to underscore the reputation of extruded steel mesh manufacturers, who consistently demonstrate expertise and authority in the industry. These manufacturers ensure rigorous testing and quality control measures are in place to validate the integrity of their products. Customers and industries relying on extruded steel mesh can trust in its performance, assured by the certifications and thorough quality checks conducted throughout the production process. In sum, extruded steel mesh continues to prove itself an indispensable material in crafting the world around us. Combining extensive research, industry experience, and technical expertise, this material not only meets existing needs but also anticipates future demands, ensuring it remains a fundamental element in industrial innovation. It's these qualities that drive its growing popularity and widespread adoption across various pivotal sectors.

Latest news

-

The Versatility of Stainless Steel Wire MeshNewsNov.01,2024

-

The Role and Types of Sun Shade SolutionsNewsNov.01,2024

-

Safeguard Your Space with Effective Bird Protection SolutionsNewsNov.01,2024

-

Protect Your Garden with Innovative Insect-Proof SolutionsNewsNov.01,2024

-

Innovative Solutions for Construction NeedsNewsNov.01,2024

-

Effective Bird Control Solutions for Every NeedNewsNov.01,2024